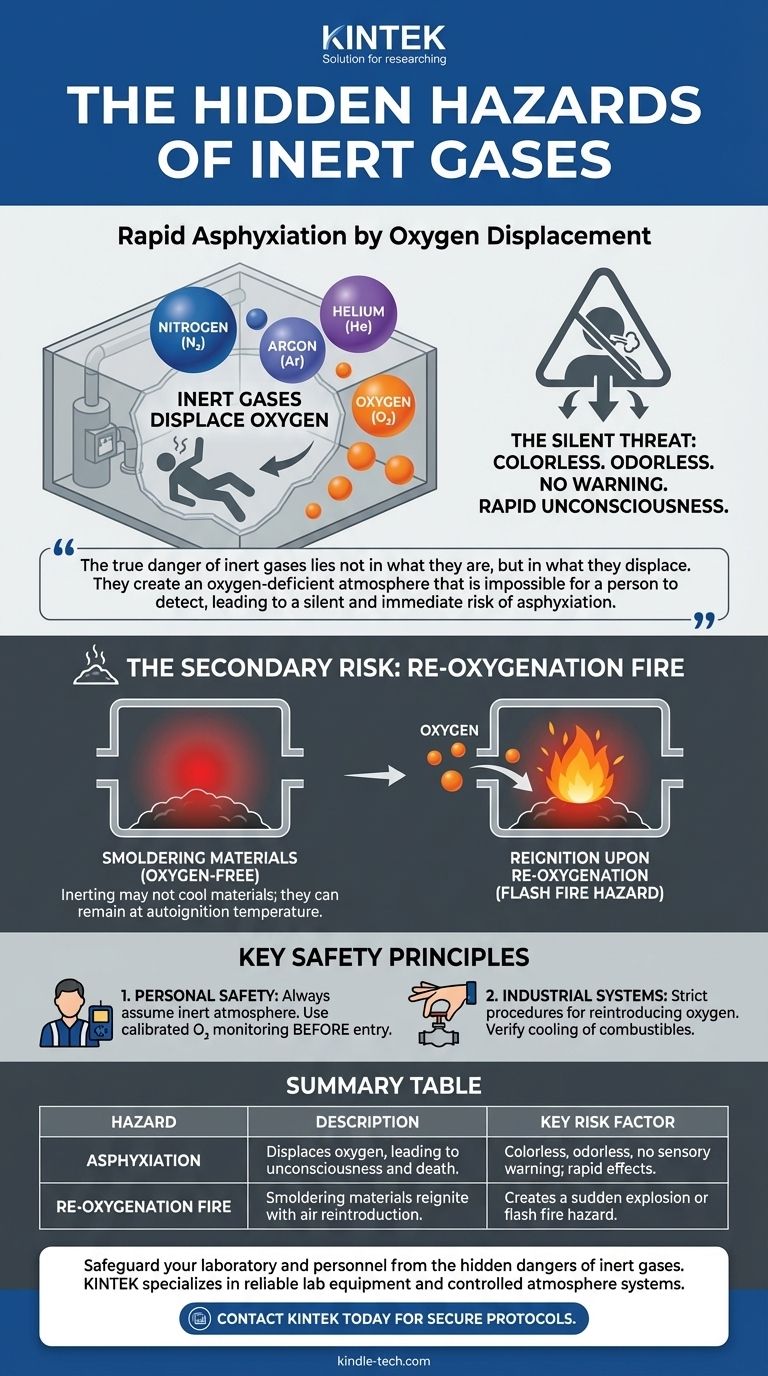

The primary hazard of inert gases is their ability to cause rapid asphyxiation by displacing oxygen. These gases—such as nitrogen, argon, and helium—are not toxic, but their presence in high concentrations reduces the breathable oxygen in the air to fatally low levels. This danger is particularly deceptive because it occurs without any sensory warning signs.

The true danger of inert gases lies not in what they are, but in what they displace. They create an oxygen-deficient atmosphere that is impossible for a person to detect, leading to a silent and immediate risk of asphyxiation and a secondary, hidden risk of fire when air is reintroduced.

The Silent Threat of Asphyxiation

The most immediate and severe hazard associated with inert gases is asphyxiation. This risk is often misunderstood because it doesn't work like a typical poison or irritant.

How Inert Gases Displace Oxygen

Inert gases are used to intentionally displace oxygen for industrial purposes, such as preventing fires or preserving materials. When released into a confined or poorly ventilated area, they physically push the normal, oxygen-rich air out of the space.

The Deceptive Nature of the Hazard

Unlike many hazardous gases, inert gases are colorless and odorless. Critically, the human body has no effective alarm system for a lack of oxygen; our reflex to breathe is primarily triggered by a buildup of carbon dioxide (CO2).

In an inert gas environment, you can exhale CO2 normally, so you do not feel the typical sensation of suffocation or the desperate urge to breathe.

Rapid and Unwarned Onset

The effect is insidious and incredibly fast. While minor oxygen deficiency might cause dizziness or a headache, these symptoms are unreliable and fleeting.

A person entering an environment with a high concentration of an inert gas can lose consciousness within seconds, often without any preliminary signs of distress. This leads to collapse, followed quickly by death if not immediately removed and resuscitated.

The Hidden Danger: Re-Oxygenation

A less obvious but equally severe hazard can occur when attempting to return a space to a normal, breathable atmosphere after it has been inerted.

The Smoldering Fire Risk

Inerting a space is an effective way to extinguish a fire by removing oxygen. However, it may not cool the combustible materials below their autoignition temperature.

These materials can continue to smolder or self-heat for a long time in the oxygen-free environment, remaining a source of extreme heat.

Creating a Flammable Atmosphere

When air is reintroduced to this space, the oxygen can cause the smoldering materials to immediately and violently reignite.

This can result in a serious fire or even an explosion within the confined space, turning a situation that seemed under control into an extremely dangerous event.

Key Safety Principles for Your Goal

Understanding these hazards is the first step toward implementing proper safety protocols. Your approach should depend on your specific context.

- If your primary focus is personal safety when entering spaces: Always assume an inert atmosphere is present where these gases are used. You must use calibrated oxygen monitoring equipment to verify the air is safe before entering any confined space.

- If your primary focus is managing an industrial inerting system: You must have strict, controlled procedures for reintroducing oxygen. This includes verifying that any potential combustible materials have been cooled sufficiently to prevent reignition.

Ultimately, treating inert gases with the same level of respect as toxic substances is the most critical principle for ensuring safety.

Summary Table:

| Hazard | Description | Key Risk Factor |

|---|---|---|

| Asphyxiation | Inert gases displace breathable oxygen, leading to unconsciousness and death. | Colorless, odorless, and provides no sensory warning; effects are rapid. |

| Re-Oxygenation Fire | Smoldering materials can violently reignite when air is reintroduced to an inerted space. | Creates a sudden explosion or flash fire hazard. |

Safeguard your laboratory and personnel from the hidden dangers of inert gases. KINTEK specializes in providing reliable lab equipment, including essential safety monitors and controlled atmosphere systems, to help you manage inert gas applications safely. Don't leave safety to chance—contact our experts today to ensure your lab protocols are secure and effective.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- 80L Chilling Circulator Cooling Water Circulator for Water Bath Cooling and Low Temperature Constant Temperature Reaction Bath

- 100L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 10L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- What are the specific applications of PTFE in micro-batch slug flow systems? Enhance Your Microfluidic Reaction Purity

- Why is PTFE wire used for hanging metal specimens in biodiesel corrosion tests? Ensure Pure Experimental Results

- How does the combination of PTFE tape and ceramic washers function in crevice corrosion modeling? Expert Analysis

- What are the process advantages of using PTFE channels in electrode installation ports? Ensure Precise Data Integrity

- How do Teflon (PTFE) baskets facilitate glass thin-film leaching? Enhance Accuracy with Chemical Inertness