The primary hazard of a power press is the point of operation, where the ram and die perform work on the material. This area is responsible for the vast majority of serious injuries, as the immense force and speed of the machine can cause crushing and amputation in an instant. Other significant hazards include unintended machine cycling, flying debris, and exposure to moving mechanical parts.

Understanding power press hazards requires looking beyond the obvious danger zone. The true risk lies in the interaction between the machine's mechanical state, its safety systems, and the human operator, where a failure in any one area can lead to a catastrophic event.

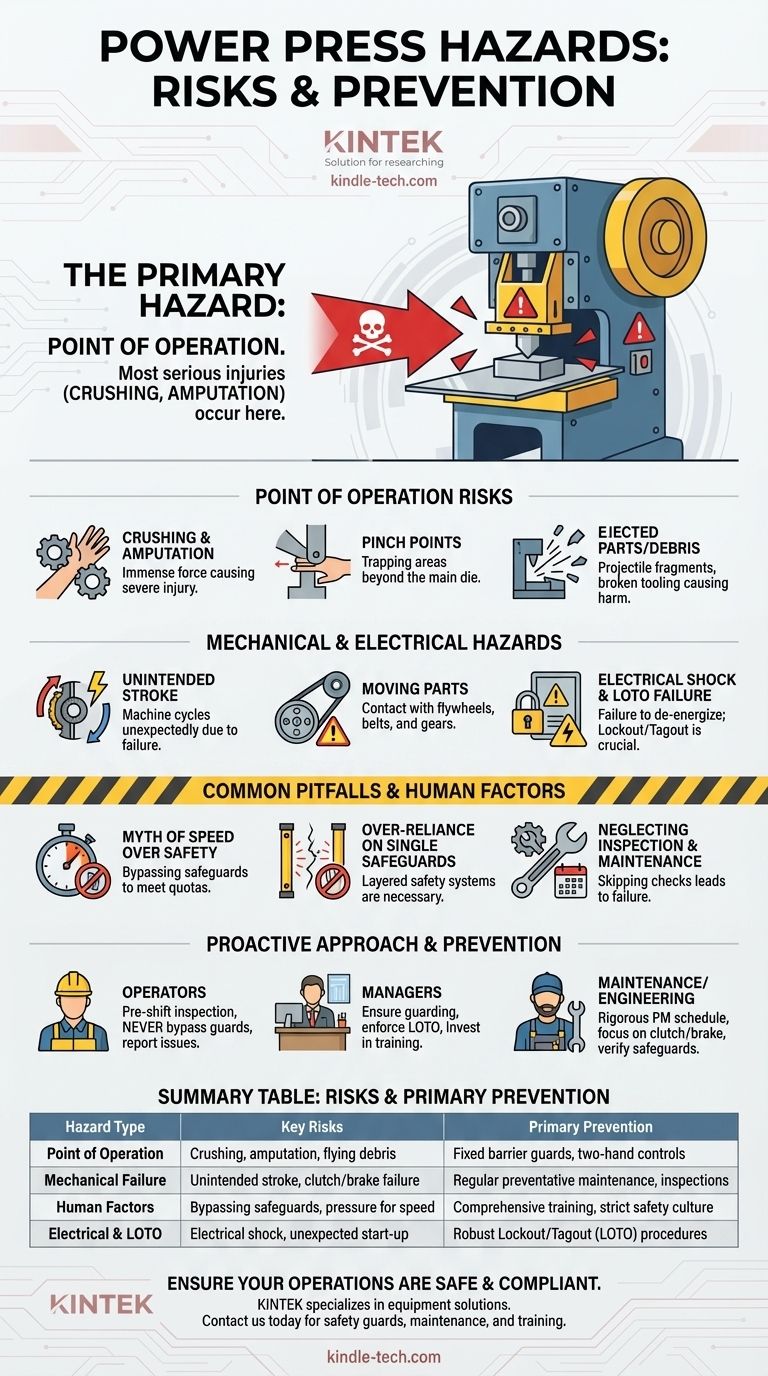

The Primary Hazard: The Point of Operation

The point of operation is where the tool and die meet to shape, punch, or shear material. It is, by design, the most dangerous part of the machine.

Crushing and Amputation

The force exerted by a power press is measured in tons and is designed to permanently deform metal. Any body part, most commonly hands and fingers, caught between the closing dies will be subjected to this force, resulting in severe crushing or amputation.

Pinch Points

Beyond the main die area, numerous other pinch points exist. These are any locations where a moving part of the press moves past a stationary part, creating a risk of trapping a limb or clothing. This includes areas around part feeders, ejectors, and the ram itself.

Ejected Parts and Debris

During operation, the press can violently eject material fragments, broken tooling, or even the workpiece itself. Without proper guarding, these projectiles can strike the operator or others in the vicinity, causing eye injuries or other serious harm.

Mechanical and Electrical Hazards

Failures within the machine's core systems introduce unpredictable and severe risks that can defeat standard operating procedures.

Unintended Stroke (Mechanical Failure)

This is one of the most feared power press failures. A worn or faulty clutch/brake mechanism can cause the press to cycle unexpectedly, even when the operator has not activated the controls. This can happen during die setting or part adjustment, when an operator's hands are most likely to be in the danger zone.

Moving Parts and Power Transmission

The flywheel, crankshaft, belts, and gears that drive the press are all significant hazards. Contact with these components during operation can cause entanglement, friction burns, and impact injuries. Proper machine guarding is essential to prevent access.

Electrical Shock and Lockout/Tagout (LOTO) Failures

Power presses are high-voltage machines. During maintenance, repair, or die changes, failing to properly de-energize and lock out the power source creates a severe risk of electrical shock or unexpected machine start-up. A robust Lockout/Tagout (LOTO) program is non-negotiable.

Common Pitfalls and Human Factors

Even a perfectly functioning machine can be hazardous if operated incorrectly or if human factors are ignored. Understanding these pitfalls is critical to building a truly safe system.

The Myth of Speed over Safety

There is often pressure to meet production quotas, which can tempt operators or supervisors to bypass or disable safety devices like light curtains or two-hand controls. This is a false economy. An accident results in far greater downtime, cost, and human tragedy than the marginal speed gained by unsafe practices.

Over-reliance on a Single Safeguard

No single safety device is infallible. A light curtain can be misaligned, and an operator can defeat two-hand controls. The safest approach is a layered system where multiple safeguards, such as fixed barrier guards combined with electronic sensors, work together to protect the operator.

Neglecting Inspection and Maintenance

A power press is a dynamic machine that undergoes immense stress. Brakes wear, clutches fail, and guards become damaged. Skipping daily operator inspections or deferring scheduled preventative maintenance is a direct path to mechanical failure and an eventual accident.

A Proactive Approach to Power Press Safety

Preventing incidents requires a systemic approach that addresses the machine, the process, and the people involved.

- If your primary focus is operating the machine: Always perform a pre-shift inspection, never bypass a safety guard for any reason, and immediately report any unusual noise or malfunction to your supervisor.

- If your primary focus is managing the work area: Ensure all presses have appropriate, functioning guards, enforce a strict Lockout/Tagout policy, and invest in comprehensive, ongoing operator training.

- If your primary focus is maintenance and engineering: Adhere to a rigorous preventative maintenance schedule, paying special attention to the clutch, brake, and safety systems, and always verify that safeguards are reinstalled correctly after any service.

Ultimately, a safe power press operation is a consistently productive and sustainable operation.

Summary Table:

| Hazard Type | Key Risks | Primary Prevention |

|---|---|---|

| Point of Operation | Crushing, amputation, flying debris | Fixed barrier guards, two-hand controls |

| Mechanical Failure | Unintended stroke, clutch/brake failure | Regular preventative maintenance, inspections |

| Human Factors | Bypassing safeguards, pressure for speed | Comprehensive training, strict safety culture |

| Electrical & LOTO | Electrical shock, unexpected start-up | Robust Lockout/Tagout (LOTO) procedures |

Ensure your power press operations are safe and compliant. The immense force of a power press demands the highest standards in safety equipment and protocols. KINTEK specializes in lab and industrial equipment, offering solutions and expertise to help you mitigate these critical risks. Our team can assist you in selecting the right safety guards, implementing preventative maintenance schedules, and training your staff on proper Lockout/Tagout procedures.

Protect your team and your productivity. Contact us today for a consultation on how we can support your commitment to a safer workplace.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the process of XRF analysis? Master Sample Prep for Accurate Results

- Why is a laboratory hydraulic press required for cold pressing titanium alloys? Key to High-Density Sintering

- What are the advantages of a power press machine? Achieve High-Speed, Cost-Effective Metal Stamping

- What is the purpose of a hydraulic press? Generate Immense Force for Shaping, Crushing, and Compacting

- Do hydraulic presses need electricity? Discover the Power Source for Your Workshop

- What is the physical mechanism for sintering Cu-Cr-Nb powders? Overcoming Oxide Barriers with Hydraulic Loading

- How does a laboratory powder pellet press facilitate the preparation of multi-layered gradient Al2O3/ZrO2 ceramic green bodies? Precision Bonding Techniques

- How strong is a hydraulic press? Unleash Immense Force with Pascal's Law