The importance of carbon nanotubes (CNTs) stems from their unique and exceptional nanoscale properties, which allow them to serve as a high-performance additive in a vast range of materials. Their primary commercial use is as a conductive additive in lithium-ion batteries, but they are also crucial for enhancing composites, films, and next-generation electronics, especially in green technologies.

Carbon nanotubes are not just a single product but a foundational "platform" material. Their true importance lies in their ability to upgrade the performance of existing materials, making them stronger, lighter, and more conductive, thereby enabling significant advancements in energy, electronics, and manufacturing.

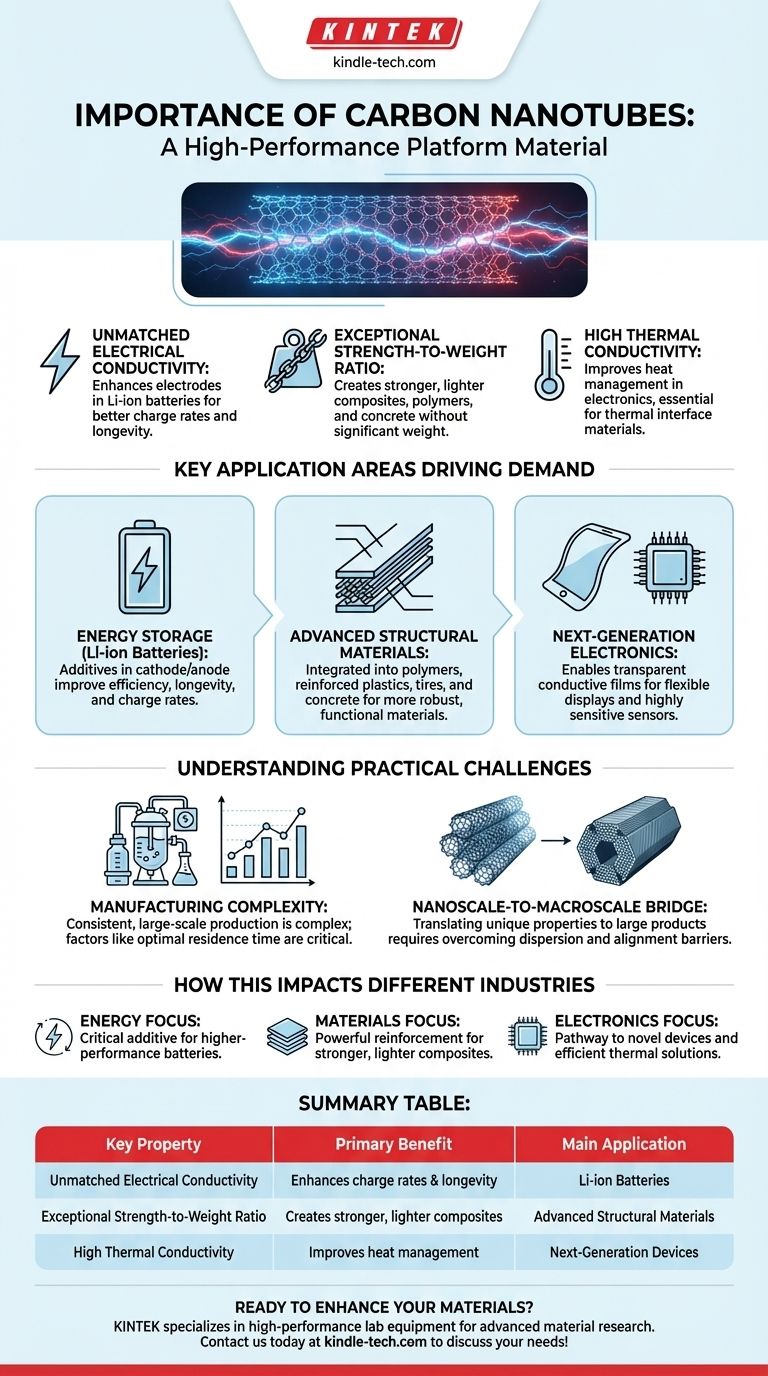

The Foundation: Why Nanoscale Properties Matter

Carbon nanotubes are substances with a size between 1 and 100 nanometers, a scale at which materials exhibit special physical and chemical properties. This unique structure is the source of their value.

Unmatched Electrical Conductivity

One of the most significant properties of CNTs is their excellent ability to conduct electricity.

This makes them an ideal additive for applications where conductivity is critical, most notably in the electrodes of lithium-ion batteries.

Exceptional Strength-to-Weight Ratio

CNTs are incredibly strong and simultaneously very lightweight.

This combination is highly sought after in composite materials, where adding a small fraction of CNTs can dramatically increase the strength and durability of polymers, concrete, asphalt, and even metals without adding significant weight.

High Thermal Conductivity

Beyond electrical properties, CNTs are also excellent conductors of heat.

This has led to their exploration and use in thermal interface materials, which are essential for managing heat in high-performance electronics and other systems.

Key Application Areas Driving Demand

The theoretical properties of CNTs are being translated into practical, high-value applications across several critical industries.

Revolutionizing Energy Storage

The most mature and significant market for CNTs is in lithium-ion batteries.

They are used as conductive additives in both the cathode and anode, improving charge rates, battery longevity, and overall efficiency.

Enhancing Structural Materials

CNTs are a key component in the future of advanced composites.

They are integrated into everything from conductive polymers and fiber-reinforced plastics to tires and concrete, creating materials that are fundamentally more robust and functional.

Enabling Next-Generation Electronics

The unique properties of CNTs are paving the way for new electronic devices.

Applications include transparent conductive films for flexible displays, highly sensitive sensors, and other emerging electronic components that rely on their nanoscale characteristics.

Understanding the Practical Challenges

Despite their immense promise, the widespread adoption of carbon nanotubes is tempered by real-world technical hurdles. Understanding these limitations is key to appreciating their current market position.

The Difficulty of Manufacturing

Producing high-quality CNTs consistently and at a large scale is a complex chemical process.

Factors like maintaining an optimal residence time during growth are crucial. Too little time wastes raw materials, while too much can limit production and create unwanted by-products.

Bridging the Nanoscale to the Macroscale

A significant challenge lies in translating the incredible properties of a single nanotube to a large-scale, practical product.

Ensuring that CNTs are properly dispersed and aligned within a composite material, for example, is a major technical barrier that researchers are actively working to overcome.

How This Impacts Different Industries

Your interest in carbon nanotubes should be guided by their specific impact on your field. They are not a universal solution, but a targeted enhancer for specific goals.

- If your primary focus is energy storage: CNTs are a critical additive for creating higher-performance, longer-lasting, and faster-charging lithium-ion batteries.

- If your primary focus is advanced materials: CNTs serve as a powerful reinforcement agent to create stronger, lighter, and more functional composites for aerospace, automotive, and construction.

- If your primary focus is next-generation electronics: CNTs offer a pathway to developing novel devices like flexible displays, ultra-sensitive sensors, and efficient thermal management solutions.

Ultimately, carbon nanotubes are a fundamental building block for the next generation of high-performance technology.

Summary Table:

| Key Property | Primary Benefit | Main Application |

|---|---|---|

| Unmatched Electrical Conductivity | Enhances charge rates & battery longevity | Lithium-ion Batteries |

| Exceptional Strength-to-Weight Ratio | Creates stronger, lighter composites | Advanced Structural Materials |

| High Thermal Conductivity | Improves heat management in electronics | Next-Generation Devices |

Ready to enhance your materials with carbon nanotubes?

KINTEK specializes in providing high-performance lab equipment and consumables for developing and testing advanced materials like CNTs. Whether you're innovating in energy storage, composites, or electronics, our solutions help you achieve superior results. Contact us today to discuss how we can support your laboratory's needs!

Visual Guide

Related Products

- Multi-zone Laboratory Tube Furnace

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Graphite Vacuum Continuous Graphitization Furnace

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What are the advantages of ion beam sputtering? Achieve Superior Thin Film Quality and Precision

- What are the future uses of CNTs? Revolutionizing Electronics, Energy, and Materials

- What is a thin film device? Unlocking the Power of Nanoscale Materials

- How strong are carbon nanotubes compared to steel? Unlocking the Potential of the Strongest Material

- What is the effect of thickness of thin film? Master Optical, Electrical, and Mechanical Properties

- What is the easiest way to make graphene? Match the Method to Your Goal

- What method is used to make thin films? A Guide to Chemical and Physical Deposition

- What are the applications of thin film semiconductor? From Microchips to Solar Energy