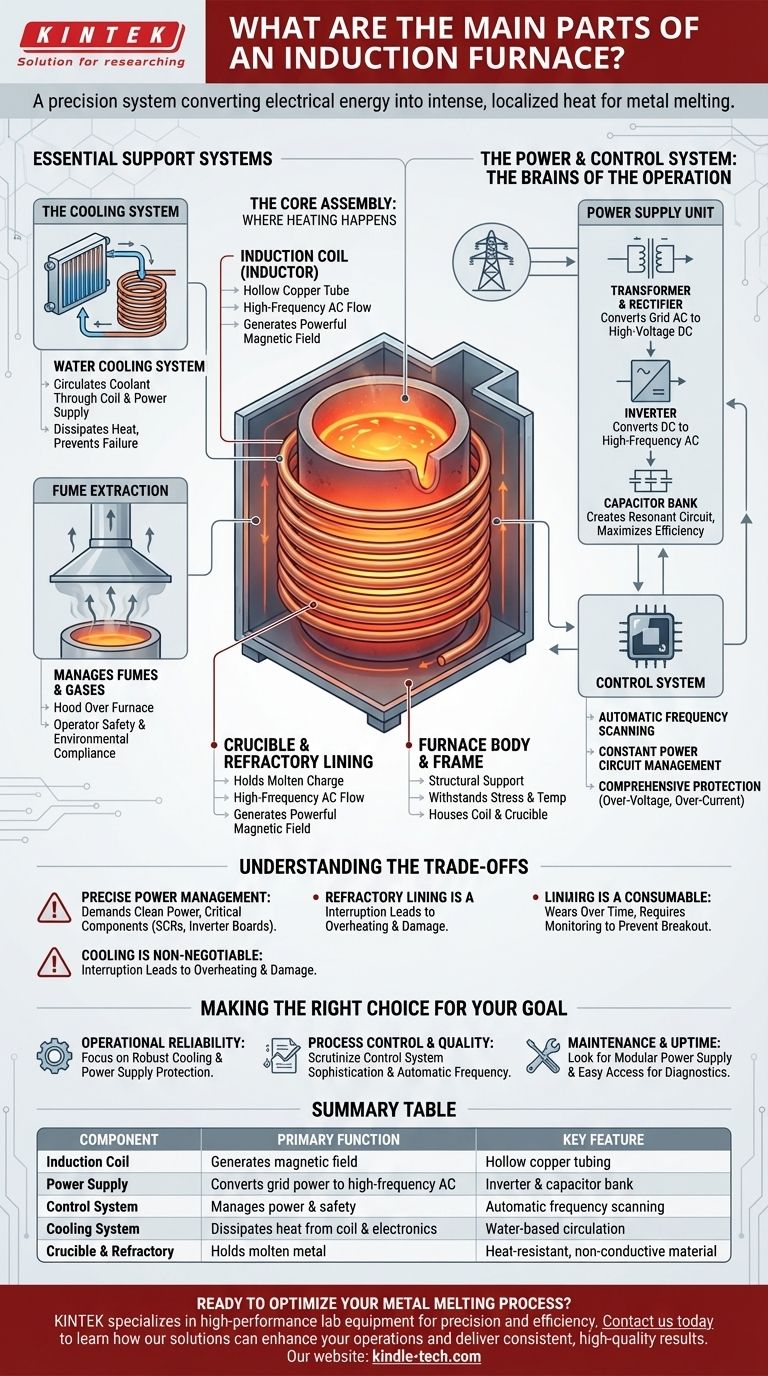

At the heart of any induction furnace is a set of core components designed to convert electrical energy into intense, localized heat. The main parts are the furnace body which houses the induction coil and crucible, a specialized power supply unit, a precision control system, and an essential cooling system. Together, these components create a powerful magnetic field that heats conductive materials from within.

An induction furnace isn't just a heater; it's a precisely controlled system. Its true function lies in how the power supply, control system, and induction coil work in concert to generate a powerful, alternating magnetic field that induces intense electrical currents directly within the material to be melted.

The Core Assembly: Where Heating Happens

The furnace assembly is the physical structure where the melting process takes place. It is designed to contain the molten material safely while withstanding extreme temperatures and powerful magnetic forces.

The Induction Coil (Inductor)

The induction coil is the primary active component. It is a hollow copper tube, wound into a coil, through which high-frequency alternating current flows.

This current generates a powerful and rapidly alternating magnetic field in the center of the coil, which is the driving force behind the entire induction heating process.

The Crucible and Refractory Lining

The crucible is the vessel that holds the metal charge. It is placed within the induction coil but does not touch it.

Crucibles are made from highly heat-resistant refractory materials that are also non-conductive, preventing them from being heated by the magnetic field. The choice of material depends on the metal being melted.

The Furnace Body and Frame

The furnace body is the structural steel framework that supports the induction coil and crucible. It is engineered to withstand the mechanical stresses and high temperatures of continuous operation.

The Power & Control System: The Brains of the Operation

This is the most complex part of the furnace. It takes standard utility power and converts it into the high-frequency, high-current power required by the induction coil, all while providing precise control and safety.

The Power Supply Unit

The power supply does not simply pass electricity to the coil. It fundamentally transforms it. Its key stages include:

- Transformer & Rectifier: Converts incoming AC power from the grid into high-voltage DC power.

- Inverter: Takes the DC power and converts it back into AC, but at a much higher and precisely controlled frequency.

- Capacitor Bank: Works with the inverter to create a resonant circuit, maximizing the efficiency of power transfer to the induction coil.

The Control System

The control system is the furnace's nerve center, often managed by a main control board with integrated circuits. It ensures stable, efficient, and safe operation.

Its duties include automatic frequency scanning to find the optimal operating point, managing a constant power circuit that adjusts voltage and current as the metal melts, and providing comprehensive protection against over-voltage or over-current faults.

Essential Support Systems

For an induction furnace to function reliably and safely, it depends on critical auxiliary systems that manage waste heat and operational logistics.

The Cooling System

The immense electrical currents flowing through the power supply and induction coil generate significant heat. A robust water cooling system is essential.

This system circulates coolant through the hollow copper induction coil and within the power supply cabinet to dissipate heat, preventing catastrophic failure of the components.

Fume Extraction

The melting process releases fumes and gases that must be safely managed. A fume extraction system, often a hood positioned over the furnace, is a critical component for operator safety and environmental compliance.

Understanding the Trade-offs

While highly efficient, induction furnaces are demanding systems with specific operational requirements that must be understood.

The Need for Precise Power Management

The high efficiency of the furnace is entirely dependent on the sophisticated power electronics. These systems require clean power and must be maintained, as components like silicon-controlled rectifiers and inverter boards are critical to operation.

Cooling is Non-Negotiable

The effectiveness of the cooling system is directly linked to the furnace's reliability and lifespan. Any interruption or reduction in cooling capacity can quickly lead to overheating and severe damage to the coil or power supply.

Refractory Lining is a Consumable

The crucible's refractory lining is subjected to extreme thermal and chemical stress. It is a consumable item that will wear out over time and must be monitored and replaced regularly to prevent a dangerous metal breakout.

Making the Right Choice for Your Goal

When evaluating or operating an induction furnace, understanding the interplay of these parts is key.

- If your primary focus is operational reliability: Pay close attention to the design of the cooling system and the comprehensiveness of the power supply's protection circuits.

- If your primary focus is process control and quality: Scrutinize the sophistication of the control system, specifically its ability to maintain constant power and adjust frequency automatically.

- If your primary focus is maintenance and uptime: Look for a modular power supply cabinet with components that are easy to access for diagnostics and repair.

By understanding how these core components function as an integrated system, you can effectively operate, maintain, and specify the right induction furnace for your application.

Summary Table:

| Component | Primary Function | Key Feature |

|---|---|---|

| Induction Coil | Generates magnetic field | Hollow copper tubing |

| Power Supply | Converts grid power to high-frequency AC | Inverter & capacitor bank |

| Control System | Manages power & safety | Automatic frequency scanning |

| Cooling System | Dissipates heat from coil & electronics | Water-based circulation |

| Crucible & Refractory | Holds molten metal | Heat-resistant, non-conductive material |

Ready to optimize your metal melting process? KINTEK specializes in high-performance lab equipment, including induction furnaces designed for precision, reliability, and efficiency. Our systems feature advanced power management, robust cooling, and intuitive controls tailored to your laboratory's needs. Contact us today to learn how our solutions can enhance your operations and deliver consistent, high-quality results.

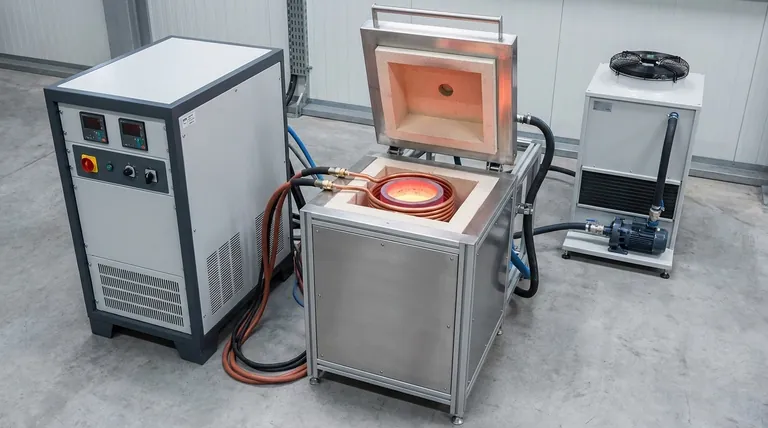

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?