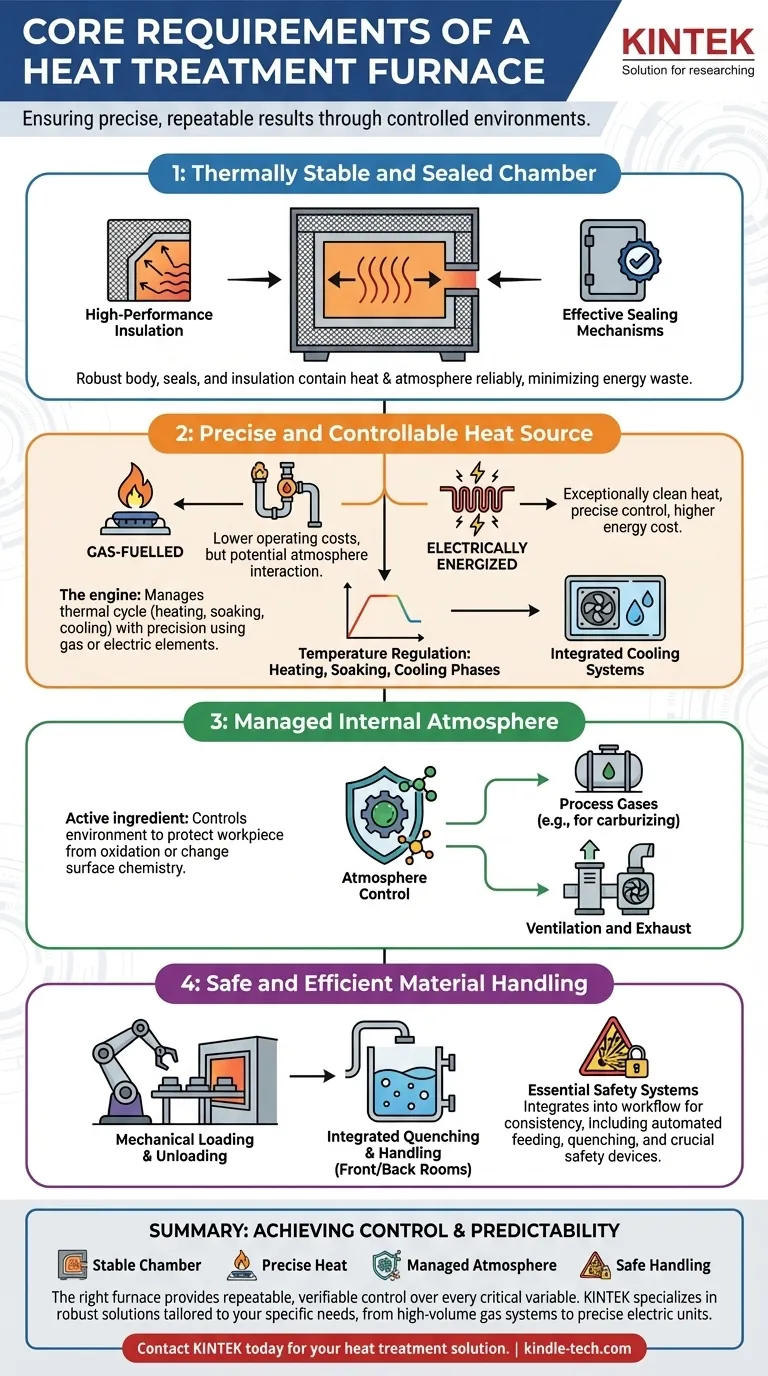

At its core, a heat treatment furnace is a highly controlled environment designed to precisely alter a material's properties. The fundamental requirements are a thermally insulated and sealed chamber, a powerful and controllable heat source, a managed internal atmosphere, and the mechanisms to safely handle the workpiece through its entire thermal cycle.

A successful heat treatment furnace isn't just about reaching high temperatures. It's about achieving absolute control over the entire process—heating, holding (soaking), and cooling—within a specific, managed atmosphere to produce a predictable and repeatable outcome in the material.

Requirement 1: A Thermally Stable and Sealed Chamber

The physical structure of the furnace is the foundation for all its functions. It must contain the heat and atmosphere reliably.

The Furnace Body

The body must be robust and well-sealed. Any leaks compromise the integrity of the internal atmosphere and lead to significant energy inefficiency.

High-Performance Insulation

Excellent insulation is critical for maintaining stable temperatures and ensuring energy efficiency. A well-insulated furnace top, for example, should not significantly exceed 300°C, proving that heat is being contained and used effectively rather than wasted.

Effective Sealing Mechanisms

Doors, ports, and any other openings must have robust sealing mechanisms. This is non-negotiable for furnaces that use a controlled atmosphere, as it prevents contamination from outside air and the escape of internal gases.

Requirement 2: A Precise and Controllable Heat Source

The "engine" of the furnace is its thermal system. It must not only generate heat but also manage it with precision throughout the treatment cycle.

Heating Elements

The primary heat source is typically either gas-fuelled or electrically energized. The choice between them depends on cost, precision requirements, and the specific heat treatment process.

Sophisticated Temperature Regulation

A heat treatment process is not static. The control system must manage different phases: a rapid heating period to reach the target temperature, followed by a "soaking" period where a constant temperature is maintained with precision.

Integrated Cooling Systems

Controlled cooling is often as critical as controlled heating. Many furnaces incorporate fast cooling chambers or integrate with external quenching tanks to complete the metallurgical transformation correctly.

Requirement 3: A Managed Internal Atmosphere

For most advanced heat treatments, the atmosphere inside the furnace is an active ingredient in the process.

Atmosphere Control

The furnace must contain a controlled atmosphere to protect the workpiece. This can prevent oxidation (scaling) or be used to actively change the surface chemistry of the part, such as in carburizing or nitriding.

Ventilation and Exhaust

A dedicated ventilation and exhaust system, often including a sealed and water-cooled fan, is required. This system safely manages process gases, maintains correct furnace pressure, and purges the chamber when needed.

Understanding the Trade-offs: Gas vs. Electric Heating

The choice of heat source is one of the most significant decisions, presenting a clear trade-off between operational cost and process purity.

Gas-Fired Furnaces

Gas furnaces generally have lower operating costs. However, the products of combustion can interact with the furnace atmosphere, which may be unacceptable for highly sensitive processes that demand extreme purity.

Electrically Heated Furnaces

Electric furnaces provide exceptionally clean heat and offer very precise temperature control. This makes them ideal for sensitive alloys and complex treatments, though their operational energy costs are typically higher.

Requirement 4: Safe and Efficient Material Handling

A furnace must integrate seamlessly into a production workflow, which requires mechanisms for handling parts safely and efficiently.

Mechanical Loading and Unloading

For consistency and operator safety, many industrial furnaces use mechanical or automated devices to feed parts into the furnace and extract them after the cycle is complete.

Integrated Quenching and Handling

The system often includes front and back rooms, elevators, and integrated quenching tanks. This allows the hot workpiece to be moved from the heating chamber to the cooling or quenching medium without being exposed to outside air.

Essential Safety Systems

Given the high temperatures, flammable gases, and high pressures involved, safety is paramount. All controllable atmosphere furnaces must be equipped with appropriate safety and explosion-proof devices to protect personnel and equipment.

Making the Right Choice for Your Application

Selecting a furnace begins with a clear understanding of your process goals.

- If your primary focus is high-volume, repeatable processing: Prioritize furnaces with automated material handling and continuous operation capabilities.

- If your primary focus is precision treatment of sensitive alloys: An electrically heated furnace with advanced atmosphere control offers the highest level of purity and accuracy.

- If your primary focus is operational efficiency and lower running costs: A well-designed gas-fired furnace is often the most economical choice, provided atmosphere purity is not the absolute top priority.

Ultimately, the right furnace is one that provides repeatable, verifiable control over every critical variable in your heat treatment process.

Summary Table:

| Requirement | Key Function | Key Components |

|---|---|---|

| Thermally Stable & Sealed Chamber | Contains heat and atmosphere | Robust body, high-performance insulation, effective door seals |

| Precise & Controllable Heat Source | Manages the thermal cycle | Heating elements (gas/electric), temperature regulation, cooling systems |

| Managed Internal Atmosphere | Protects workpiece and enables surface treatments | Atmosphere control, ventilation, and exhaust systems |

| Safe & Efficient Material Handling | Integrates into workflow and ensures operator safety | Mechanical loading/unloading, integrated quenching, safety systems |

Ready to achieve precise, repeatable heat treatment results?

KINTEK specializes in laboratory equipment and consumables, providing robust heat treatment furnaces tailored to your specific process needs. Whether you require the purity of electric heating for sensitive alloys or the cost-efficiency of gas-fired systems for high-volume processing, our expertise ensures you get the right solution for predictable outcomes.

Contact us today to discuss your application and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance