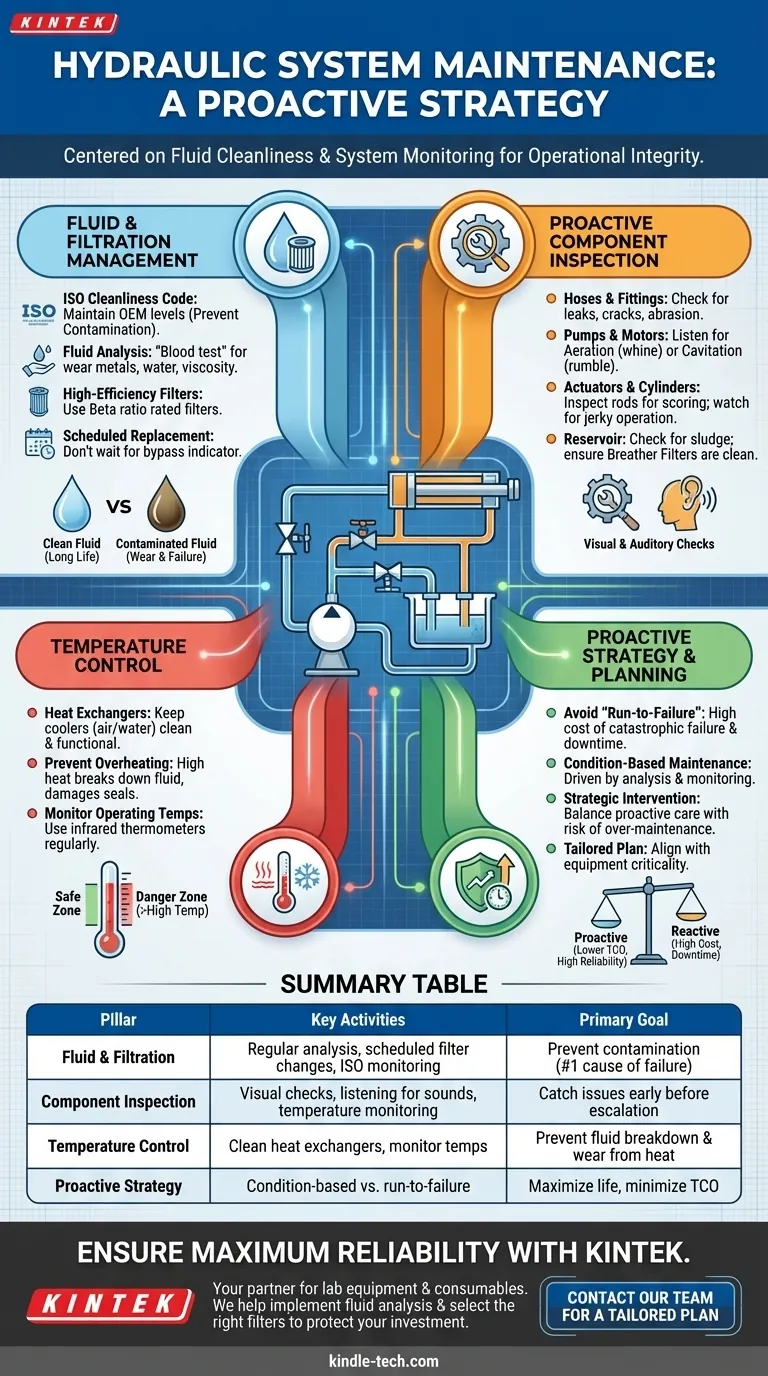

At its core, hydraulic system maintenance revolves around four key pillars: managing the fluid, changing the filters, inspecting the components, and controlling the temperature. These activities are not isolated tasks but part of a comprehensive strategy to maintain system cleanliness and operational integrity, as contamination and heat are the primary causes of nearly all hydraulic failures.

The single most important principle of hydraulic maintenance is this: it is a proactive strategy centered on fluid cleanliness and system monitoring, not a reactive checklist. The condition of the hydraulic fluid is a direct indicator of the health of the entire system.

The Foundation: Fluid and Filtration Management

The hydraulic fluid is the lifeblood of the system. It transmits power, lubricates components, transfers heat, and carries away contaminants. Its health is non-negotiable.

Why Fluid Cleanliness is Critical

Contamination is the primary cause of hydraulic component wear and failure. Particulate matter—dirt, metal flakes, and seal fragments—acts like liquid sandpaper, eroding tight-tolerance surfaces inside pumps, valves, and motors.

The goal is to maintain a specific fluid ISO Cleanliness Code, which is a measure of particulate contamination. Following the original equipment manufacturer's (OEM) recommended cleanliness level is essential for reliability.

The Power of Regular Fluid Analysis

Think of fluid analysis as a blood test for your machinery. Sending a small sample to a lab provides critical data on the system's internal condition.

This analysis can detect wear metals (indicating which component is failing), water content (which causes corrosion and fluid breakdown), and changes in viscosity before they lead to a catastrophic failure.

The Role of Filtration

Filters are the system's kidneys, tasked with removing harmful contaminants from the fluid. However, not all filters are created equal.

A filter's Beta ratio indicates its capture efficiency at a specific particle size. Using high-quality filters that meet or exceed OEM specifications is a direct investment in the longevity of your hydraulic components.

Scheduled Filter Replacement

Do not wait for the filter bypass indicator to activate. By that point, contaminated fluid is already being sent directly to your sensitive components.

Filters should be replaced on a schedule based on operating hours or as recommended by fluid analysis. Always remember to also service the case drain filters on pumps and motors and the breather filters on the reservoir, which prevent airborne moisture and dirt from entering the system.

Proactive Component Inspection and Monitoring

Regular, observant inspections are your best tool for catching problems before they escalate. This involves more than just looking for leaks; it requires using your senses.

Hoses, Fittings, and Seals

Visually inspect all hoses for cracking, abrasion, and blistering. Check every fitting for leaks. A minor drip can quickly become a major failure and represents a point where contaminants can enter the system.

Pumps and Motors

Listen for changes in sound. A high-pitched whining may indicate aeration (air entering the system through leaks), while a lower-pitched rumbling can signal cavitation (fluid vaporizing due to flow restrictions), both of which are destructive to the pump. Use an infrared thermometer to check for excessive operating temperatures.

Actuators and Cylinders

Check cylinder rods for scoring or pitting, which can damage seals and introduce contaminants. Watch for jerky or slow operation, which may indicate internal leakage or air in the system.

Reservoir and Heat Exchangers

The reservoir is more than a holding tank. Periodically check inside for sludge or sediment. Most importantly, ensure the heat exchanger (cooler) is clean and functioning. Clogged fins on an air cooler or low flow in a water cooler will cause the system to overheat.

Understanding the Trade-offs: Reactive vs. Proactive

Your approach to maintenance directly impacts your operational costs and reliability.

The High Cost of "Run-to-Failure"

A reactive, run-to-failure approach may seem cheaper in the short term, but it leads to catastrophic outcomes. A single component failure can send a shockwave of contamination through the entire system, requiring a complete, and extremely expensive, system flush and the replacement of multiple components. Unplanned downtime is always more costly than planned maintenance.

The Long-Term Value of Proactive Care

A proactive maintenance program based on schedules and condition monitoring (like fluid analysis) significantly extends the life of components. It reduces unplanned downtime and lowers the total cost of ownership over the equipment's lifespan.

The Risk of Over-Maintenance

There is a risk in being too invasive. Every time a hydraulic system is opened to replace a component, there is a chance of introducing contamination. Maintenance should be strategic and precise, guided by a clear schedule and data from inspections and fluid analysis.

Creating Your Hydraulic Maintenance Plan

Your specific strategy should align with the criticality of the equipment and your operational goals.

- If your primary focus is maximum reliability for critical equipment: Implement a condition-based maintenance program driven by routine fluid analysis and temperature monitoring.

- If your primary focus is cost-effective care for standard machinery: Establish a rigorous time-based schedule for fluid and filter changes and empower operators to perform daily visual inspections.

- If you are troubleshooting an existing problem: Always start with the fluid and filters, as they provide a clear history of the system's internal health and will guide your next steps.

Ultimately, consistent and intelligent maintenance transforms a hydraulic system from a potential liability into a reliable asset.

Summary Table:

| Maintenance Pillar | Key Activities | Primary Goal |

|---|---|---|

| Fluid & Filtration | Regular fluid analysis, scheduled filter changes, ISO cleanliness monitoring | Prevent contamination, the #1 cause of failure |

| Component Inspection | Visual checks for leaks, listening for unusual sounds, temperature monitoring | Catch issues early before they escalate |

| Temperature Control | Ensuring heat exchangers and coolers are clean and functional | Prevent fluid breakdown and component wear from overheating |

| Proactive Strategy | Condition-based monitoring vs. run-to-failure approach | Maximize system life and minimize total cost of ownership |

Ensure your lab's hydraulic equipment operates with maximum reliability.

A proactive maintenance strategy is key to avoiding unplanned downtime and costly repairs. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you implement a fluid analysis program and select the right filters to protect your investment.

Contact our team today to discuss a maintenance plan tailored to your specific hydraulic systems and operational goals.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- Vacuum Cold Trap Direct Cold Trap Chiller

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

People Also Ask

- What is the function of a laboratory hydraulic press in post-torrefaction? Transform Biochar into Energy-Dense Fuel

- Why is KBr used as a mulling agent? Achieve Clear IR Spectroscopy Results

- What is the function of a Laboratory Hydraulic Press in AlxCoCrFeNi HEA preparation? Engineered Porosity for Synthesis

- What causes hydraulic pressure spikes? Prevent System Damage from Hydraulic Shock

- How is XRF testing done? A Step-by-Step Guide to Elemental Analysis

- What is the specific application of a laboratory hydraulic press in the formation of lithium-air battery air electrodes?

- What are the safety precautions for KBr? Achieve Flawless FTIR Pellet Preparation and Data Accuracy

- How is a hydraulic press used to verify contaminated electrolyte solidification? Ensure 17-26 MPa Safety Compliance