At their core, modern dental ceramics are primarily glass-ceramics, advanced materials engineered for both beauty and durability. The two most prominent categories used for restorations like crowns and bridges are leucite-based ceramics and lithium disilicate-based ceramics. The selection between them hinges on the specific clinical demands for strength and aesthetics.

The central challenge in dental restorations is balancing strength with appearance. The type of ceramic chosen is therefore a deliberate decision based on the location of the tooth, the biting forces it must endure, and the aesthetic goal of the procedure.

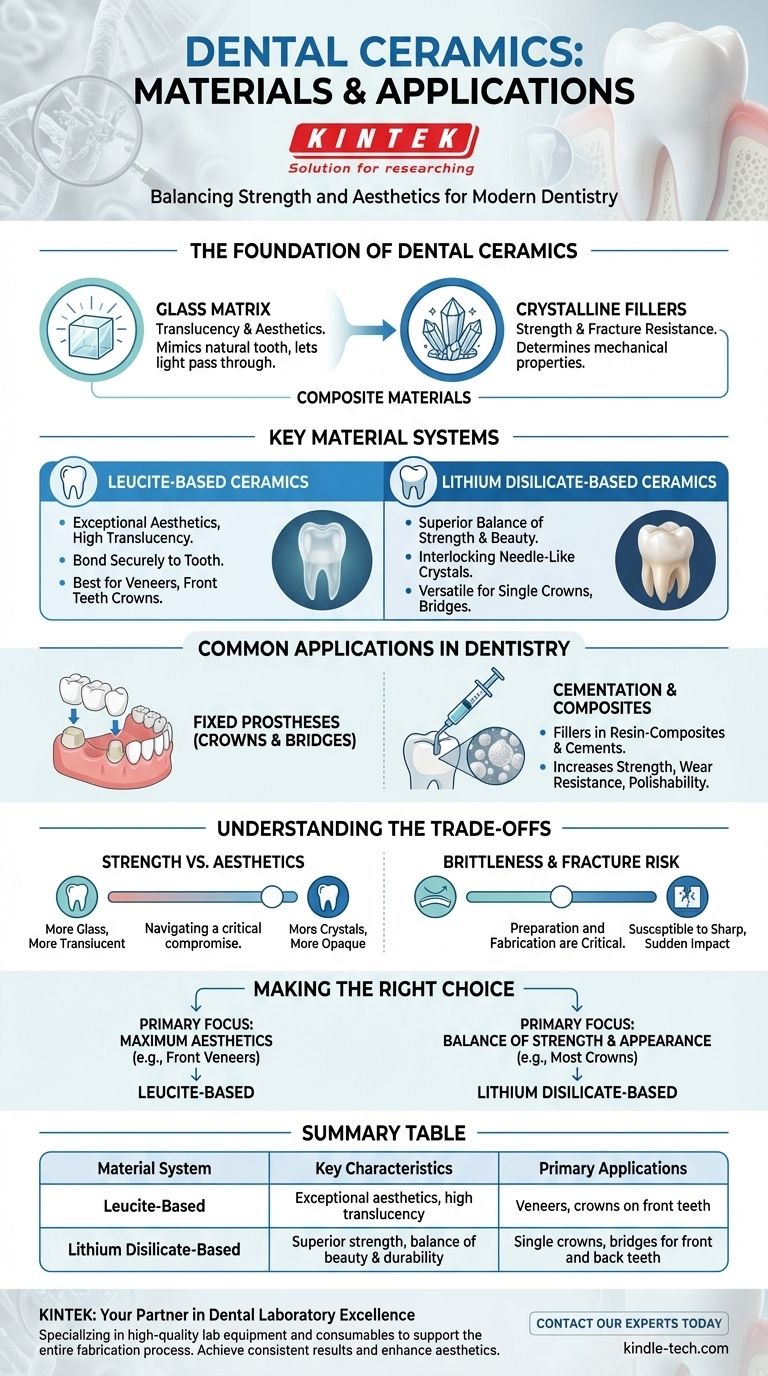

The Foundation of Dental Ceramics

Dental ceramics are composite materials, meaning they are a blend of different components. Their unique properties come from the precise ratio of a glass matrix to crystalline fillers.

The Glass Matrix

The glassy component provides the material's translucency and aesthetic qualities. It allows light to pass through the restoration, mimicking the appearance of a natural tooth.

The Crystalline Fillers

Crystals are dispersed within the glass to provide strength and fracture resistance. The type, size, and amount of these crystals fundamentally determine the material's mechanical properties.

Key Ceramic Material Systems

The two systems mentioned in your inquiry represent different approaches to balancing the glass-to-crystal ratio for optimal performance.

Leucite-Based Ceramics

Leucite is a type of crystal incorporated into a glass matrix. These ceramics are renowned for their exceptional aesthetics and ability to be bonded securely to tooth structure.

They are an excellent choice for restorations where appearance is the primary concern, such as veneers or crowns on front teeth.

Lithium Disilicate-Based Ceramics

This material contains a high concentration of needle-like lithium disilicate crystals, which interlock to create a remarkably strong and durable structure.

Lithium disilicate offers a superior balance of strength and beauty, making it a versatile and popular choice for single crowns and bridges in nearly any part of the mouth.

Common Applications in Dentistry

These advanced materials are not just used for crowns; they are integral to several aspects of modern restorative dentistry.

Fixed Prostheses (Crowns & Bridges)

This is the most common application. A crown made from lithium disilicate, for example, can withstand significant chewing forces while still looking natural.

Cementation and Composites

Ceramic particles are often used as fillers in resin-composite filling materials and dental cements. These particles increase the strength, wear resistance, and polishability of the final restoration.

Understanding the Trade-offs

No single material is perfect for every situation. The choice of a dental ceramic always involves navigating a critical trade-off.

Strength vs. Aesthetics

The fundamental compromise is between mechanical strength and visual appearance. Increasing the crystalline content makes a ceramic stronger but often more opaque, reducing its natural translucency.

A highly aesthetic, glass-rich ceramic may not be suitable for a molar that endures immense biting force. Conversely, the strongest materials may not be the first choice for a highly visible front tooth.

Brittleness and Fracture Risk

While strong, all ceramics are brittle materials. This means they are more susceptible to fracturing under sharp, sudden impact compared to metals.

The dentist's preparation of the tooth and the precise fabrication of the restoration are critical to minimize stress points and ensure long-term success.

Making the Right Choice for Your Goal

The selection of a dental ceramic is a clinical decision tailored to the unique needs of each patient and tooth.

- If your primary focus is maximum aesthetics (e.g., front tooth veneers): A leucite-based or other high-translucency glass-ceramic is often the ideal choice.

- If your primary focus is a balance of strength and appearance (e.g., most crowns): A lithium disilicate-based ceramic provides a robust and beautiful solution for both front and back teeth.

Ultimately, advances in these materials empower dental professionals to restore function and create beautiful, long-lasting smiles.

Summary Table:

| Material System | Key Characteristics | Primary Applications |

|---|---|---|

| Leucite-Based | Exceptional aesthetics, high translucency | Veneers, crowns on front teeth |

| Lithium Disilicate-Based | Superior strength, balance of beauty and durability | Single crowns, bridges for front and back teeth |

KINTEK: Your Partner in Dental Laboratory Excellence

Choosing the right ceramic material is critical for creating durable, aesthetically perfect dental restorations. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to the precise needs of dental laboratories. Our products support the entire fabrication process, ensuring you achieve optimal results with materials like leucite and lithium disilicate ceramics.

We help you:

- Achieve consistent, high-strength results with reliable processing equipment.

- Enhance aesthetic outcomes with precision tools and consumables.

- Streamline your workflow for crowns, bridges, and veneers.

Ready to elevate your dental restorations? Contact our experts today to discuss how KINTEK's solutions can meet your specific laboratory needs and drive your success.

Visual Guide

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Hexagonal Boron Nitride HBN Ceramic Ring

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Engineering Advanced Fine Alumina (Al₂O₃) Ceramic Positioning Pin Straight Bevel for Precision Applications

- Boron Nitride (BN) Crucible for Phosphorous Powder Sintered

People Also Ask

- What is sintering dental materials? The Key to Durable, High-Strength Dental Restorations

- What is the firing temperature for dental ceramics? Mastering the Critical Cycle for Strong, Aesthetic Restorations

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the major drawback of all-ceramic restorations in the posterior of the mouth? Overcoming Fracture Risk for Long-Lasting Results

- What is the effect of high speed sintering on zirconia? Dramatically Faster Cycles with Critical Trade-offs

- What is in a dental laboratory? Discover the High-Tech Hub Creating Your Perfect Smile

- Are ceramic crowns stain-resistant? Discover the Secret to a Lasting, Bright Smile

- Do ceramic crowns look natural? Achieve a Seamless, Natural-Looking Smile