At their core, the mechanical applications of carbon nanotubes (CNTs) revolve around their use as a nano-scale reinforcement additive. While widely known for their electrical properties, their unparalleled strength and low weight allow them to be mixed in small quantities into bulk materials like polymers, concrete, and metals to dramatically enhance their structural integrity, durability, and performance.

The primary role of CNTs in mechanical applications is not to act as a standalone material, but to function as microscopic rebar within a larger material matrix, stopping cracks from forming and transferring stress with incredible efficiency.

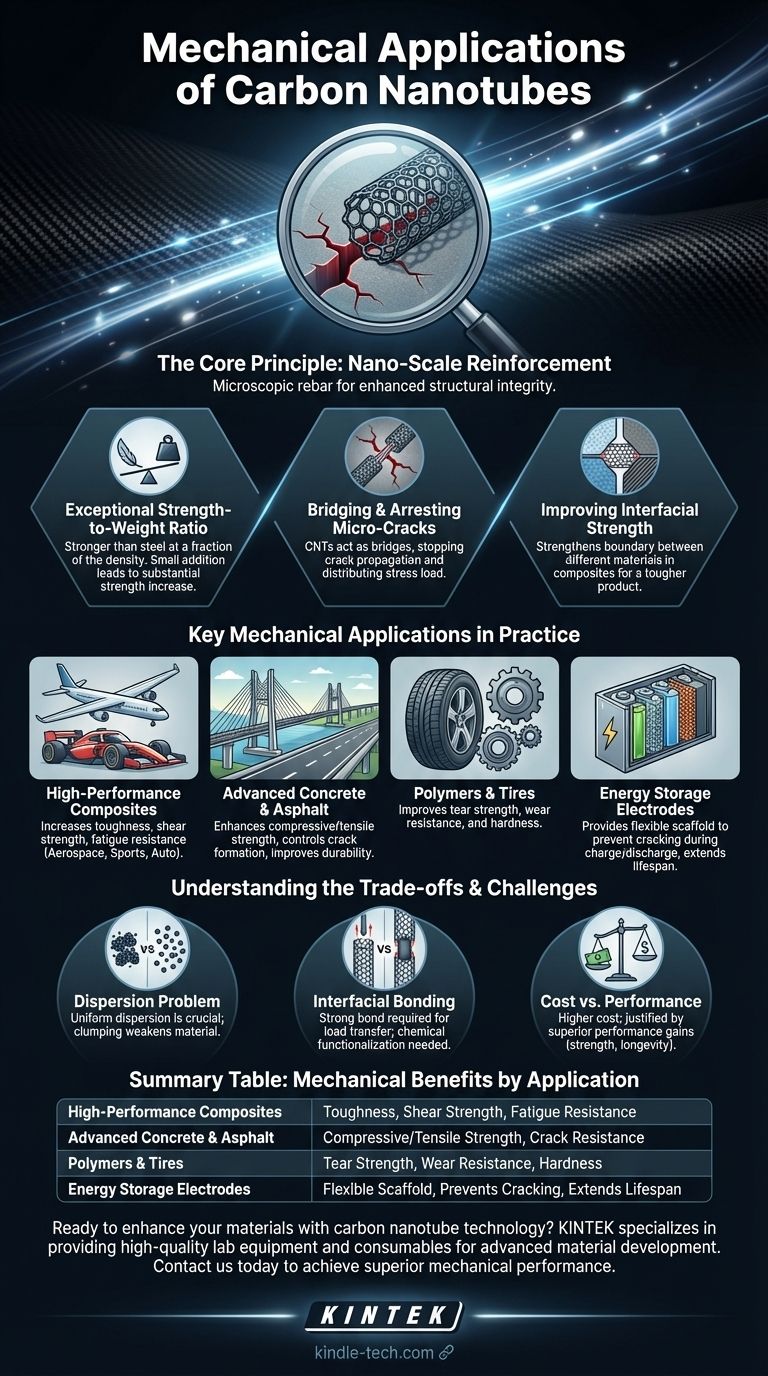

The Core Principle: Nano-Scale Reinforcement

To understand the mechanical applications of CNTs, you must first grasp how they work on a microscopic level. They are not typically used to build large objects directly but are dispersed into other materials.

Exceptional Strength-to-Weight Ratio

CNTs possess one of the highest strength-to-weight ratios of any known material. They are significantly stronger than steel but at a fraction of the density.

This property means that adding even a very small percentage of CNTs by weight can lead to a substantial increase in the composite material's overall strength without adding significant mass.

Bridging and Arresting Micro-Cracks

Nearly all material failures begin as microscopic cracks. When dispersed properly within a material matrix like a polymer or concrete, CNTs act as bridges across these tiny imperfections.

As stress is applied and a micro-crack begins to form, it encounters a nanotube. The nanotube's immense strength stops the crack from propagating, effectively transferring the stress load across the flaw and distributing it throughout the bulk material.

Improving Interfacial Strength

In composites, the boundary (or interface) between different materials is often the weakest point. For example, in a carbon fiber reinforced polymer, the bond between the fibers and the polymer matrix is critical.

CNTs can be used to strengthen this interface, creating a more robust bond between the primary reinforcement (like carbon fiber) and the matrix, leading to a tougher and more durable final product.

Key Mechanical Applications in Practice

The principle of nano-scale reinforcement has been successfully applied across several industries, moving CNTs from the laboratory to real-world components.

High-Performance Composites

This is a primary application area. CNTs are added to the resin (epoxy) matrix of fiber-reinforced polymers, which are used in aerospace, high-end sporting goods, and automotive components.

Here, they enhance the toughness, shear strength, and fatigue resistance of the composite material, complementing the larger carbon or glass fibers.

Advanced Concrete and Asphalt

Adding a small fraction of a percent of CNTs to a concrete mix can significantly increase its compressive and tensile strength. The CNTs control the formation of micro-cracks that occur as the concrete cures and is subjected to load.

This results in a more durable material that is more resistant to cracking and has a longer service life, which is also being explored for asphalt in high-wear road applications.

Enhancing Polymers and Tires

In the tire industry, CNTs are used as an additive to rubber. They improve tear strength and wear resistance, leading to longer-lasting tires.

Beyond tires, they are used in a wide range of conductive and non-conductive polymers to improve mechanical properties like tensile strength and hardness for applications ranging from industrial components to electronics casings.

A Supporting Role in Energy Storage

While the primary function of CNTs in lithium-ion batteries is to enhance electrical conductivity, their mechanical properties are a critical secondary benefit.

The incredible strength of CNTs provides a flexible, robust scaffold within the battery electrode. This prevents the electrode material from cracking and degrading during the physical expansion and contraction that occurs while charging and discharging, directly improving the battery's lifespan and stability.

Understanding the Trade-offs and Challenges

While the benefits are significant, leveraging CNTs effectively comes with critical engineering challenges that must be addressed for any successful application.

The Dispersion Problem

This is the single most important hurdle. CNTs have a strong tendency to clump together (agglomerate) due to van der Waals forces. If they are not properly dispersed, these clumps act as defects, weakening the material instead of strengthening it.

Achieving a uniform, homogenous dispersion within a matrix is a complex and often proprietary manufacturing step that is essential for performance.

Interfacial Bonding

For a CNT to transfer load effectively, it must bond well to the surrounding material matrix. A weak bond means the nanotube will simply pull out of the matrix under stress, providing no reinforcement benefit.

Chemical modification of the nanotube surface, known as functionalization, is often required to ensure strong adhesion to the specific polymer or material being used.

Cost vs. Performance

High-quality carbon nanotubes remain more expensive than traditional additives like carbon black or glass fibers. Their use must be justified by a performance requirement that cheaper alternatives cannot meet.

The decision to use CNTs is an economic one, balancing the added material cost against the value of increased strength, longevity, or weight reduction.

Making the Right Choice for Your Goal

The decision to integrate CNTs for mechanical enhancement depends entirely on your specific performance target and economic constraints.

- If your primary focus is maximum strength and lightweighting: Consider CNTs for advanced composites in applications like aerospace or performance sports, where the high cost is justified by unparalleled performance gains.

- If your primary focus is durability and service life: Explore CNTs as an additive in bulk materials like concrete, asphalt, or industrial polymers, where a small addition can significantly reduce life-cycle costs.

- If your primary focus is creating a multifunctional material: Use CNTs where their mechanical strength supports another key property, such as enabling stable, long-lasting electrodes in batteries or creating durable, conductive plastics.

By understanding them as a targeted reinforcement tool rather than a miracle material, you can effectively leverage their properties to solve specific engineering challenges.

Summary Table:

| Application Area | Key Mechanical Benefit |

|---|---|

| High-Performance Composites | Increases toughness, shear strength, and fatigue resistance |

| Advanced Concrete & Asphalt | Enhances compressive/tensile strength and crack resistance |

| Polymers & Tires | Improves tear strength, wear resistance, and hardness |

| Energy Storage Electrodes | Provides flexible scaffold to prevent cracking and extend lifespan |

Ready to enhance your materials with carbon nanotube technology? KINTEK specializes in providing high-quality lab equipment and consumables for advanced material development. Whether you're working on next-generation composites, durable construction materials, or innovative energy storage solutions, our expertise can help you achieve superior mechanical performance. Contact us today to discuss how we can support your laboratory's specific needs and drive your projects forward.

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Electrode Polishing Material for Electrochemical Experiments

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- Is it possible during the synthesis of CNTs to determine its chirality? Master the Challenge of CNT Purity Control

- What are thin films in physics? Unlocking Unique Properties at the Nanoscale

- What is the sputtering rate? Master the Key to Controlling Your Thin Film Deposition

- What factors influence step coverage in deposition processes? Mastering Uniformity for High Aspect Ratio Features

- Which parameters affect sputter yield using an ion beam? Master Ion Energy, Mass, Angle & Material Properties

- What is RF and DC sputtering? Choose the Right Thin-Film Deposition Technique

- What are the disadvantages of sputtering deposition? Slower Rates, Higher Costs & Process Complexity

- Can SiO2 be sputtered? RF vs. Reactive Sputtering for Superior SiO2 Films