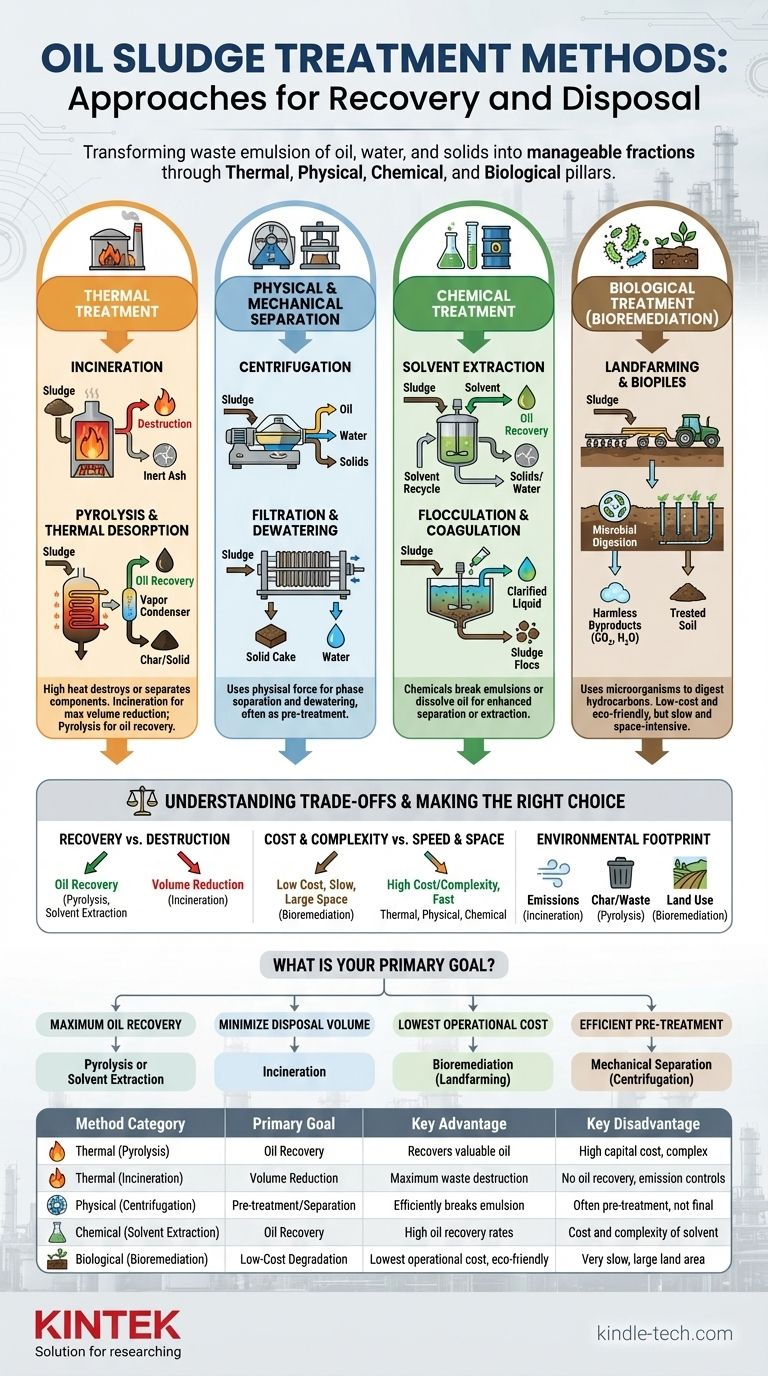

When confronting oil sludge, the available treatment methods are best categorized into four primary approaches: thermal, physical, chemical, and biological. Each approach uses a different fundamental principle to achieve the common goals of separating the oil, water, and solid phases, reducing overall volume, and enabling either resource recovery or safe disposal.

The core challenge of oil sludge treatment is not a lack of options, but selecting the right one. The optimal method is always a function of your primary goal: maximizing resource recovery, minimizing final waste volume, or achieving the lowest-cost compliant disposal.

The Four Pillars of Sludge Treatment

Understanding oil sludge requires seeing it not as a single substance, but as a stable emulsion of oil, water, and solids (like sand, rust, and organic sediment). Effective treatment is simply the process of breaking this emulsion and handling each component.

Thermal Treatment Methods

These methods leverage heat to either destroy or separate the sludge components. They are often fast and highly effective but can be energy-intensive.

Incineration

This is a high-temperature combustion process that completely destroys the organic and hydrocarbon components of the sludge.

It results in the greatest possible volume reduction, leaving behind only an inert solid ash. However, it offers no oil recovery and requires strict air pollution controls to manage emissions.

Pyrolysis and Thermal Desorption

These methods use heat in a low-oxygen or oxygen-free environment. Instead of burning the sludge, this process vaporizes the water and hydrocarbons, allowing them to be collected and condensed separately.

This is a key method for recovering the oil fraction. The solid byproduct is a dry, often carbon-rich material called "char," which must be managed or disposed of.

Physical and Mechanical Separation

These methods use physical force to separate the sludge phases without changing their chemical nature. They are often used as a crucial pre-treatment step to make other processes more efficient.

Centrifugation

High-speed centrifuges, particularly three-phase decanter centrifuges, are the workhorses of sludge treatment. They use powerful G-forces to separate the sludge into its distinct oil, water, and solid phases.

This method is highly effective for breaking the emulsion and significantly reducing the volume that requires further, more intensive treatment.

Filtration and Dewatering

Techniques like filter presses or belt presses are used to squeeze the liquid out of the sludge. This is primarily a dewatering step to increase the solid content and reduce the overall volume of the waste.

Chemical Treatment

This approach uses chemicals to break the emulsion and make physical separation easier or to extract valuable components.

Solvent Extraction

A specific solvent is mixed with the sludge to dissolve the oil, pulling it away from the water and solids. The oil-rich solvent is then separated, and the solvent is recovered for reuse, leaving behind the crude oil.

This method can achieve very high oil recovery rates but involves the cost and complexity of handling and recycling large volumes of solvent.

Flocculation and Coagulation

Chemicals are added to the sludge that cause the fine solid particles to clump together into larger masses, or "flocs." These heavier flocs then settle out of the liquid phase much more easily, clarifying the water and oil.

Biological Treatment (Bioremediation)

This method uses naturally occurring microorganisms to digest and break down the hydrocarbon components of the sludge into harmless substances like carbon dioxide and water.

Landfarming and Biopiles

In landfarming, sludge is spread over a prepared area of land and periodically tilled to aerate it. In biopiles, the sludge is mixed with bulking agents and formed into a pile with aeration pipes.

Bioremediation is often the lowest-cost and most environmentally friendly option. However, it is very slow, can require large areas of land, and its effectiveness is dependent on factors like climate and sludge toxicity.

Understanding the Trade-offs

No single method is universally superior. The correct choice involves a clear-eyed assessment of competing priorities.

Recovery vs. Destruction

The most fundamental trade-off is whether you want to recover the oil or simply get rid of the waste.

- Recovery-focused methods like pyrolysis and solvent extraction preserve the value of the hydrocarbons but are more complex.

- Destruction-focused methods like incineration offer maximum volume reduction but sacrifice any potential resource value.

Cost and Complexity

A bioremediation landfarm has very low capital and operational costs but is slow and land-intensive. A sophisticated pyrolysis plant is highly efficient and recovers valuable oil but requires a significant upfront investment and skilled operators.

Environmental and Regulatory Footprint

Incineration requires stringent air emission controls. Landfarming requires monitoring to prevent groundwater contamination. Pyrolysis produces a solid char that must be tested and managed as a potential waste stream. Every method has a regulatory consequence.

Sludge Composition is Key

The characteristics of your specific sludge will heavily influence your choice. Sludge with very high water content is an excellent candidate for initial dewatering with centrifuges. Sludge with low oil content may not justify the expense of a recovery-focused method like pyrolysis.

Making the Right Choice for Your Goal

Base your decision on a clear understanding of your primary objective.

- If your primary focus is maximum oil recovery: Pyrolysis or solvent extraction are your most effective options, turning a waste liability into a potential asset.

- If your primary focus is minimizing final waste volume for disposal: Incineration provides the most significant and immediate reduction, simplifying your final disposal logistics.

- If your primary focus is the lowest operational cost with ample time and space: Bioremediation offers a sustainable and low-cost, albeit slow, solution for degrading the hydrocarbon content.

- If your primary focus is pre-treatment or efficiently de-emulsifying raw sludge: Mechanical separation with three-phase centrifuges is the industry standard for the initial processing step.

By aligning your chosen method with your specific operational goals and constraints, you transform a complex waste problem into a manageable engineering challenge.

Summary Table:

| Method Category | Primary Goal | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Thermal (Pyrolysis) | Oil Recovery | Recovers valuable oil fraction | High capital cost, complex operation |

| Thermal (Incineration) | Volume Reduction | Maximum waste destruction | No oil recovery, requires emission controls |

| Physical (Centrifugation) | Pre-treatment/Separation | Efficiently breaks emulsion | Often a pre-treatment step, not a final solution |

| Chemical (Solvent Extraction) | Oil Recovery | High oil recovery rates | Cost and complexity of solvent handling |

| Biological (Bioremediation) | Low-Cost Degradation | Lowest operational cost, eco-friendly | Very slow, requires large land area |

Struggling to Select the Right Oil Sludge Treatment Method?

The optimal path depends entirely on your specific sludge composition and primary goal: maximizing oil recovery, minimizing disposal volume, or achieving the lowest cost. KINTEK specializes in providing the laboratory equipment and consumables needed to analyze your sludge and pilot these treatment processes effectively.

We help our customers in the environmental and oil & gas sectors make data-driven decisions. Contact us today via our [#ContactForm] to discuss how our solutions can help you transform your sludge from a liability into an asset or ensure compliant, efficient disposal.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- What are the three primary stages of the freeze-drying process? Master Precise Lyophilization for Your Lab

- What industries can benefit from freeze drying technology? Preserve Value in Pharma, Food & More

- Why does freeze drying extend the shelf life of products? Preserve Nutrition & Flavor for Years

- Which industries commonly utilize freeze drying techniques? The Key to Preserving High-Value Products

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures