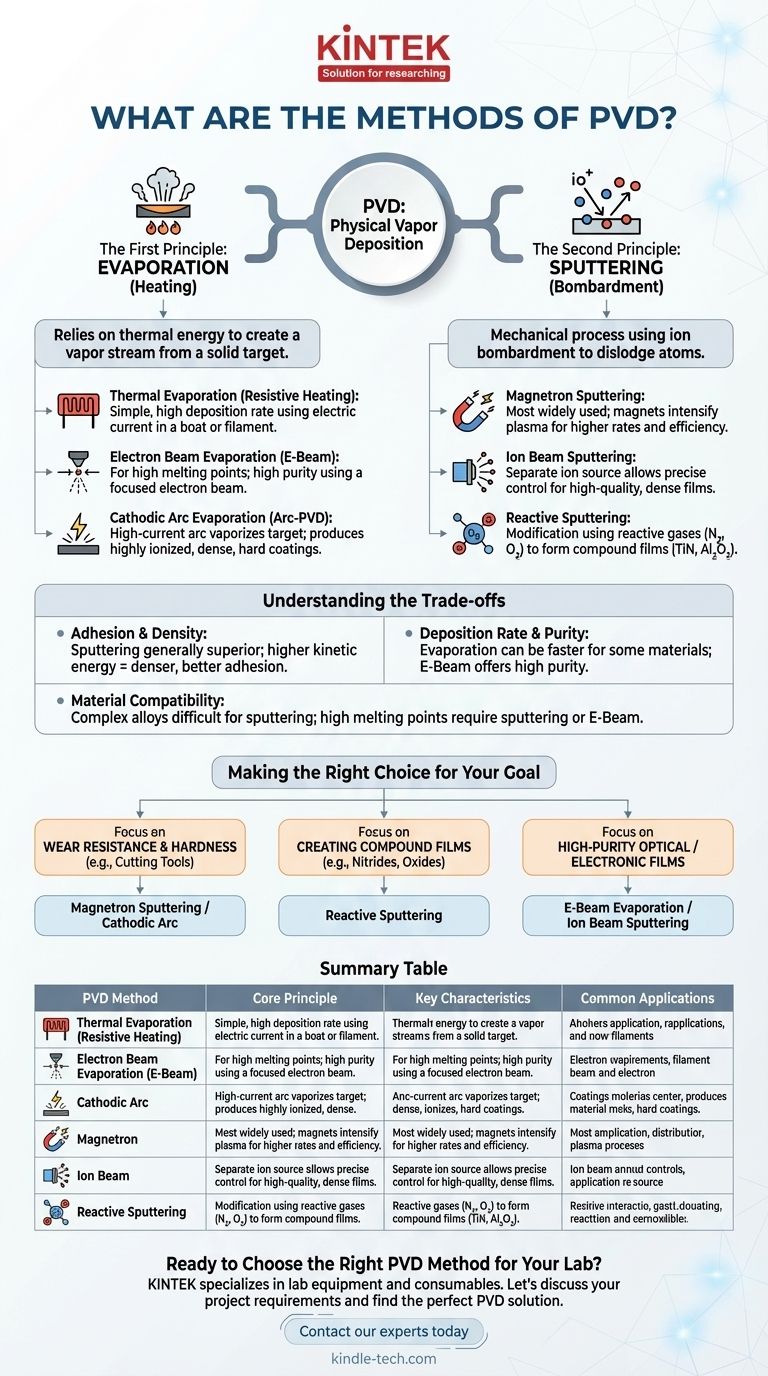

The primary methods of Physical Vapor Deposition (PVD) are fundamentally categorized into two distinct families: evaporation and sputtering. The most common industrial techniques include magnetron sputtering, cathodic arc evaporation, and thermal evaporation, each designed to transform a solid material into a vapor that can be deposited as a high-performance thin film.

The critical difference between PVD methods isn't the specific machine used, but the physical principle employed. Your choice ultimately comes down to one of two actions: you either heat a material until it evaporates, or you bombard it with ions to knock atoms loose.

The First Principle: Evaporation

Evaporation techniques rely on thermal energy to create a vapor stream. A solid source material, known as the "target," is heated in a high vacuum until its atoms gain enough energy to boil off or sublimate into the vapor phase, which then condenses on the substrate.

Thermal Evaporation (Resistive Heating)

This is one of the simplest PVD methods. An electric current is passed through a high-resistance boat or filament containing the source material, generating intense heat and causing the material to evaporate.

Electron Beam Evaporation (E-Beam)

For materials with very high melting points, an electron beam is used as the heat source. A high-intensity beam of electrons is magnetically guided to strike the target material, creating a localized spot of intense heat that generates a vapor stream with high purity.

Cathodic Arc Evaporation (Arc-PVD)

This method uses a high-current, low-voltage electric arc to vaporize the target material. The arc creates small, highly energetic emissive spots on the cathode (target) surface that locally heat and vaporize the material, producing a highly ionized vapor that results in very dense and hard coatings.

The Second Principle: Sputtering

Sputtering is a mechanical, not thermal, process. It uses momentum transfer from energetic ions to dislodge, or "sputter," atoms from the surface of the target material. A plasma is typically used to create a steady supply of these bombarding ions.

Magnetron Sputtering

This is arguably the most widely used PVD technique today. Magnets are placed behind the target to trap electrons near its surface. This intensifies the plasma, leading to a much higher rate of ion bombardment and therefore a faster, more efficient deposition process.

Ion Beam Sputtering

In this technique, the ion source is separate from the target. An ion beam is generated and then accelerated toward the target, providing precise control over the energy and flux of the bombarding ions. This allows for the creation of extremely high-quality, dense films.

Reactive Sputtering

Reactive sputtering is not a standalone method but a modification of another sputtering process, usually magnetron sputtering. A reactive gas (like nitrogen or oxygen) is intentionally introduced into the vacuum chamber. The sputtered metal atoms react with this gas to form a compound film, such as titanium nitride (TiN) or aluminum oxide (Al₂O₃), directly on the substrate.

Understanding the Trade-offs: Evaporation vs. Sputtering

Neither principle is universally superior; the choice depends entirely on the desired properties of the final coating.

Adhesion and Density

Sputtering generally produces coatings with higher density and better adhesion. The sputtered atoms arrive at the substrate with much higher kinetic energy than evaporated atoms, effectively embedding themselves into the surface and creating a denser film structure.

Deposition Rate and Purity

Evaporation can offer higher deposition rates for certain materials, making it more efficient for thicker coatings. Electron beam evaporation, in particular, can produce films of very high purity because the heat source is highly localized.

Material Compatibility

Some complex alloys can be difficult to sputter uniformly, as one element may be sputtered more easily than another. Conversely, some materials have melting points that are too high for simple thermal evaporation, making sputtering or E-beam evaporation necessary.

Making the Right Choice for Your Goal

Selecting the correct PVD method requires aligning the process capabilities with your application's primary requirement.

- If your primary focus is wear resistance and hardness (e.g., cutting tools): Magnetron sputtering or cathodic arc evaporation are the leading industrial choices due to the dense, highly adherent films they produce.

- If your primary focus is creating compound films (e.g., nitrides, oxides): Reactive sputtering is the designated process, as it is designed to form these compounds during deposition.

- If your primary focus is high-purity optical or electronic films: Electron beam evaporation or ion beam sputtering provide the highest degree of control over contamination and film properties.

Understanding the core principle—heating versus bombardment—is the key to selecting the ideal PVD method for your specific application.

Summary Table:

| PVD Method | Core Principle | Key Characteristics | Common Applications |

|---|---|---|---|

| Thermal Evaporation | Heating (Resistive) | Simple, high deposition rate | Thin films for basic research |

| Electron Beam (E-Beam) Evaporation | Heating (Electron Beam) | High purity, high melting point materials | Optical coatings, electronics |

| Cathodic Arc Evaporation | Heating (Electric Arc) | Highly ionized vapor, dense/hard coatings | Wear-resistant tools |

| Magnetron Sputtering | Bombardment (Plasma) | High density, excellent adhesion, versatile | Decorative, functional coatings |

| Ion Beam Sputtering | Bombardment (Ion Beam) | Precise control, high-quality films | Precision optics, semiconductors |

| Reactive Sputtering | Bombardment + Chemical Reaction | Forms compound films (e.g., TiN) | Hard, decorative coatings |

Ready to Choose the Right PVD Method for Your Lab?

Selecting the ideal PVD technique is critical for achieving the specific film properties—like hardness, purity, or adhesion—that your research or production requires. The choice between evaporation and sputtering depends entirely on your application's goals.

KINTEK specializes in lab equipment and consumables, providing the expertise and reliable PVD solutions you need to succeed. We help laboratories like yours navigate these technical decisions to enhance efficiency and results.

Let's discuss your project requirements and find the perfect PVD solution for you.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method