Diamond-Like Carbon (DLC) coatings are a class of amorphous carbon films defined by a unique combination of properties typically found only in natural diamond. Their primary characteristics are exceptional hardness, an extremely low coefficient of friction, and high wear resistance, making them a premier choice for protecting critical components from mechanical failure.

The term "DLC" does not refer to a single material, but a family of coatings. The core challenge for any engineer is understanding that the properties of DLC can be precisely tuned, meaning success lies not just in choosing DLC, but in selecting the right type of DLC for a specific application.

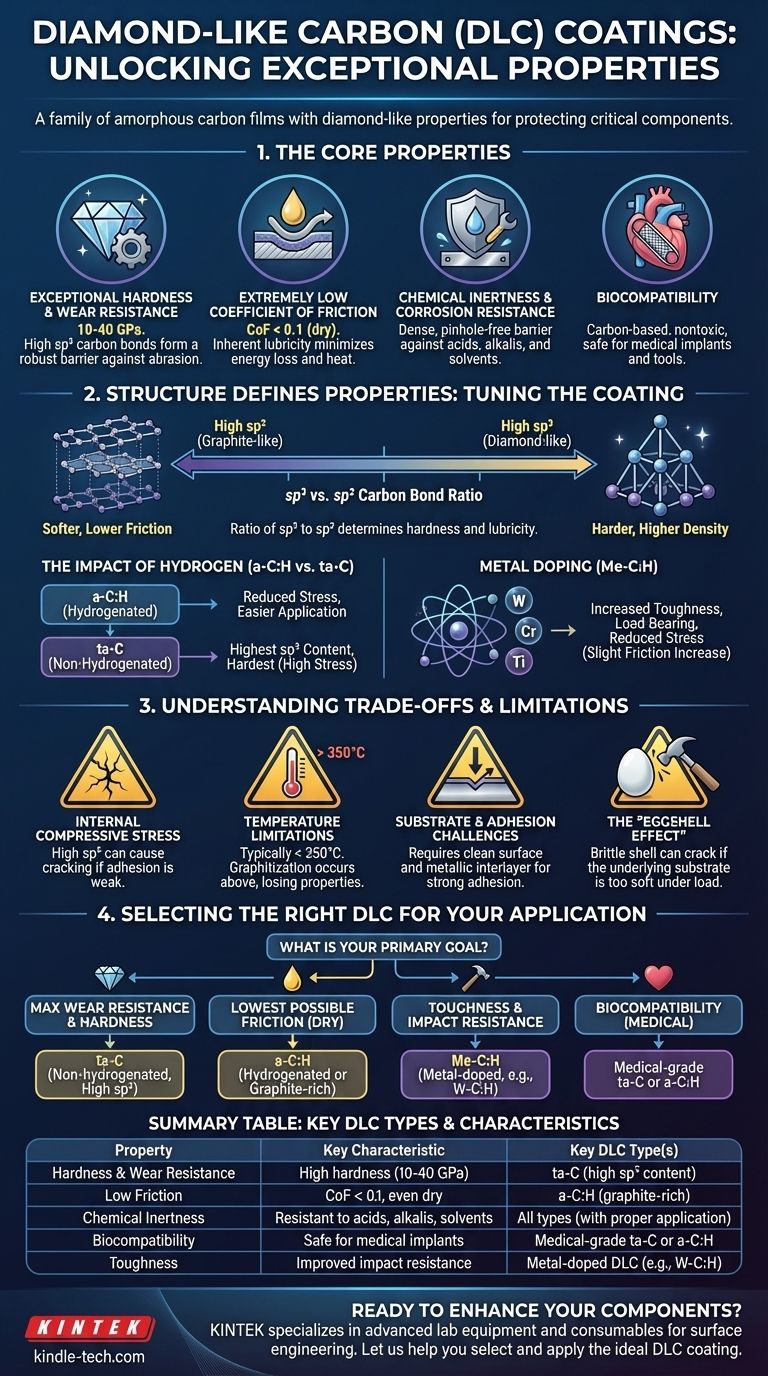

The Core Properties That Define DLC

DLC's value comes from its ability to impart diamond-like properties onto the surface of less durable materials like steel, aluminum, and titanium.

Exceptional Hardness and Wear Resistance

DLC coatings are exceptionally hard, often measuring between 10 and 40 GPa (GigaPascals). For context, most hardened steels are below 10 GPa.

This hardness stems from a dense, amorphous structure containing a high percentage of sp³ hybridized carbon bonds, the same type of incredibly strong bonds found in natural diamond. This structure provides a robust barrier that directly protects a component's surface from abrasive and adhesive wear.

Extremely Low Coefficient of Friction

One of the most valuable properties of DLC is its inherent lubricity. Many DLC variants exhibit a coefficient of friction below 0.1, a level typically associated with wet, lubricated conditions, yet DLC can achieve this in a dry environment.

This ultra-low friction minimizes energy loss, reduces heat generation between moving parts, and prevents surface seizure under high load.

Chemical Inertness and Corrosion Resistance

The dense, pinhole-free nature of a well-applied DLC coating makes it an excellent chemical barrier. It is largely inert and does not react with common acids, alkalis, or solvents.

This property protects the underlying substrate material from corrosion and chemical attack, extending the life of components in harsh operational environments.

Biocompatibility

Because they are primarily composed of carbon, many forms of DLC are biocompatible. They do not release toxic elements into the body or trigger a significant immune response.

This has made DLC a critical coating for medical implants, such as orthopedic joints, coronary stents, and surgical tools, where wear resistance and biological safety are paramount.

Why "DLC" Is Not One Material: The Role of Structure

The specific properties of a DLC coating are determined by its atomic structure. Understanding these variations is key to choosing the correct formulation.

The sp³ vs. sp² Carbon Bond Ratio

The defining characteristic of any DLC is the ratio of diamond-like sp³ bonds to graphite-like sp² bonds.

- High sp³ content results in higher hardness, rigidity, and density.

- High sp² content results in a softer coating but contributes to lower friction and better lubricity.

The deposition process is controlled to achieve the ideal ratio for the intended application.

The Impact of Hydrogen (a-C:H vs. ta-C)

DLCs are broadly categorized by the presence of hydrogen.

- Hydrogenated Amorphous Carbon (a-C:H) is the most common type. Hydrogen helps stabilize the atomic structure and reduce internal stress, making it easier to apply.

- Tetrahedral Amorphous Carbon (ta-C) is non-hydrogenated and has the highest concentration of sp³ bonds. It is the hardest and most diamond-like form of DLC but contains significant internal stress.

The Use of Metal Doping (Me-C:H)

To further tune properties, metals such as Tungsten (W), Chromium (Cr), or Titanium (Ti) can be incorporated into the DLC structure.

Metal doping can increase the coating's toughness, improve its load-bearing capacity, and reduce high internal stress. However, this often comes at the cost of a slight increase in the coefficient of friction compared to pure DLC.

Understanding the Trade-offs and Limitations

While powerful, DLC coatings are not a universal solution. Their limitations must be respected for a successful application.

Internal Compressive Stress

The very thing that makes some DLCs hard—a high sp³ content—also creates high internal compressive stress. If this stress exceeds the coating's adhesion strength to the substrate, it can spontaneously crack or delaminate. This is often managed with specialized adhesion layers and process controls.

Temperature Limitations

Most commercially available DLC coatings, particularly hydrogenated forms, are limited to service temperatures below 350°C (660°F). Above this temperature, the structure begins to break down in a process called graphitization, where the hard sp³ bonds convert to soft sp² bonds, causing the coating to lose its beneficial properties.

Substrate and Adhesion Challenges

DLC requires an extremely clean surface and often a metallic interlayer to achieve strong adhesion. Furthermore, the most common application methods (Physical Vapor Deposition) are line-of-sight processes, making it difficult to coat complex internal geometries uniformly.

The "Eggshell Effect"

DLC coatings are extremely hard but also very thin and brittle. If the underlying substrate is too soft, a sharp impact can deform the substrate, causing the rigid DLC "shell" to crack and fail. The substrate must be sufficiently hard to support the coating under load.

Selecting the Right DLC for Your Application

Choosing the correct DLC formulation is a matter of prioritizing your primary engineering goal.

- If your primary focus is maximum wear resistance and hardness: A non-hydrogenated tetrahedral amorphous carbon (ta-C) coating is the best choice due to its superior sp³ content.

- If your primary focus is the lowest possible friction for dry running: A hydrogenated (a-C:H) or graphite-rich DLC provides the best lubricity.

- If your primary focus is toughness and impact resistance: A metal-doped DLC (like W-C:H) offers reduced internal stress and better load support.

- If your primary focus is biocompatibility for medical use: A pure, certified medical-grade ta-C or a-C:H formulation is required to ensure patient safety.

Ultimately, leveraging the power of DLC is about matching its tunable properties to the precise demands of your engineering challenge.

Summary Table:

| Property | Key Characteristic | Key DLC Type(s) |

|---|---|---|

| Hardness & Wear Resistance | High hardness (10-40 GPa), protects against abrasion | ta-C (high sp³ content) |

| Low Friction | Coefficient of friction < 0.1, even dry | a-C:H (graphite-rich) |

| Chemical Inertness | Resistant to acids, alkalis, and solvents | All types (with proper application) |

| Biocompatibility | Safe for medical implants and tools | Medical-grade ta-C or a-C:H |

| Toughness | Improved impact resistance and load capacity | Metal-doped DLC (e.g., W-C:H) |

Ready to enhance your components with the precise performance of DLC coatings?

At KINTEK, we specialize in advanced lab equipment and consumables for surface engineering. Our expertise can help you select and apply the ideal DLC coating—whether you need maximum hardness for industrial tools, the lowest friction for moving parts, or certified biocompatibility for medical devices.

We provide solutions for laboratories and manufacturers aiming to improve product longevity, efficiency, and performance. Contact our experts today to discuss how we can support your specific project requirements and bring the benefits of DLC technology to your applications.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- Does DLC coating rust? Unlock Superior Corrosion and Wear Resistance

- What is the application of plasma enhanced CVD? Enable Low-Temperature Thin Film Deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What types of materials can be deposited using PECVD? Discover Versatile Thin Film Solutions for Your Lab

- Can you DLC coat plastic? Achieve High-Performance Scratch Resistance for Your Polymer Parts

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition