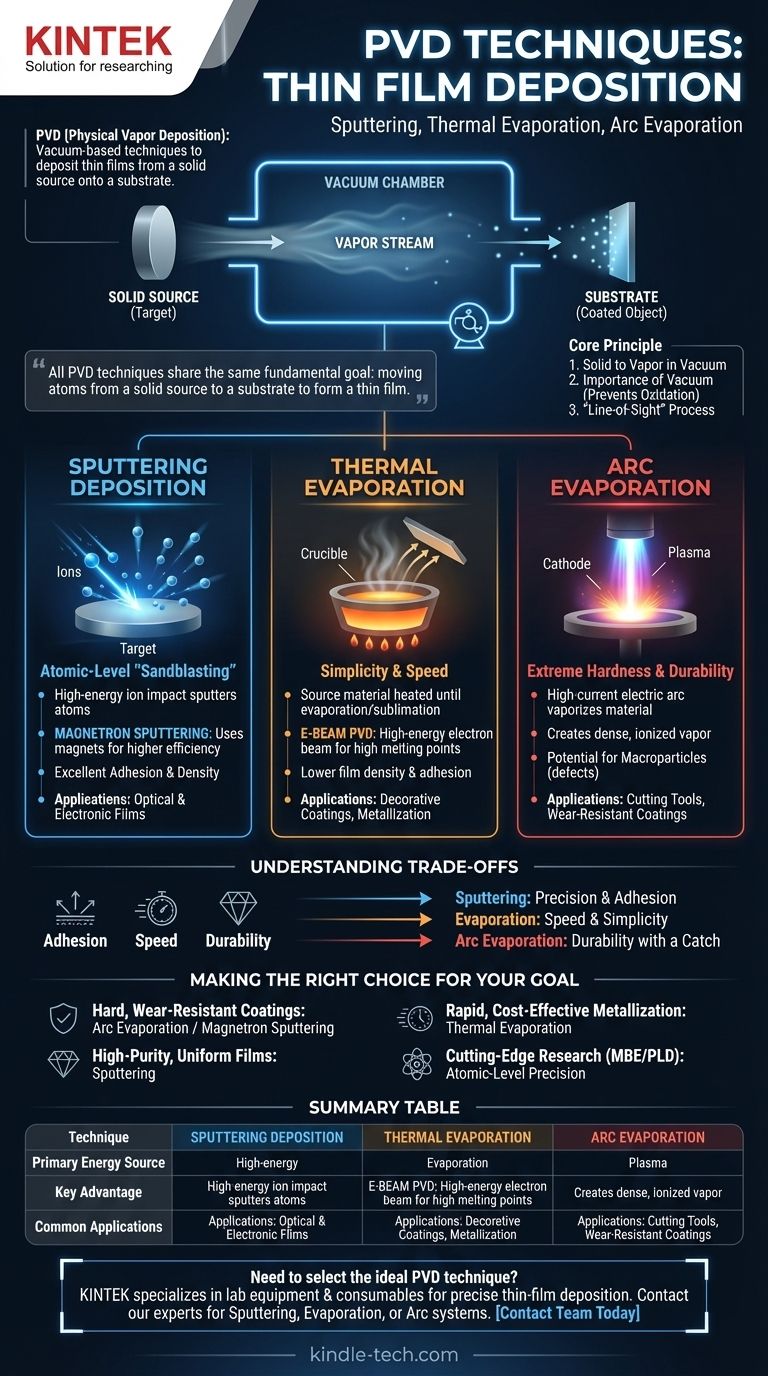

In essence, Physical Vapor Deposition (PVD) covers a family of vacuum-based techniques used to deposit thin films of material onto a substrate. The primary methods are Sputtering, Thermal Evaporation, and Arc Evaporation. While all three transform a solid source material into a vapor that then condenses as a coating, they differ significantly in how they create that vapor, which in turn dictates the film's properties and suitable applications.

All PVD techniques share the same fundamental goal: moving atoms from a solid source to a substrate to form a thin film. The critical difference lies in the method used to energize and vaporize those source atoms, a choice that directly impacts the resulting coating's density, adhesion, purity, and structure.

The Core Principle of PVD

From Solid to Vapor in a Vacuum

At its heart, every PVD process involves three steps inside a vacuum chamber: a solid source material, known as the "target," is energized until it turns into a vapor; this vapor travels through the vacuum; and it then condenses onto the object being coated (the "substrate").

The Importance of the Vacuum

The process is performed under a high vacuum to prevent the vaporized atoms from reacting with gases in the air, such as oxygen or nitrogen. A cleaner vacuum ensures a purer, higher-quality film.

A "Line-of-Sight" Process

PVD is typically a "line-of-sight" process. The vaporized atoms travel in a straight line from the source to the substrate, coating the surfaces they can directly "see." This is why complex parts often need to be rotated during coating to achieve uniform coverage.

The Primary PVD Categories

The main PVD techniques are distinguished by the energy source used to generate the vapor.

Sputtering Deposition

Sputtering is an atomic-level "sandblasting" process. High-energy ions, typically from an inert gas like argon, are accelerated to strike the source target. This impact physically knocks off, or "sputters," atoms from the target, which then deposit onto the substrate.

Magnetron Sputtering is the most common form. It uses powerful magnets behind the target to trap electrons near its surface, dramatically increasing the efficiency of the ion bombardment and allowing for faster deposition rates.

Thermal Evaporation

This is conceptually the simplest method. The source material is heated in the vacuum until it evaporates or sublimes. These gaseous atoms then travel to the substrate and condense back into a solid film.

Electron Beam Evaporation (E-Beam PVD) is an advanced form where a high-energy electron beam is aimed at the source material. This allows for the evaporation of materials with very high melting points, which would be impossible with simple resistive heating.

Arc Evaporation (Cathodic Arc)

This highly energetic method uses a high-current electric arc on the surface of the source material (the cathode). The arc creates a tiny, intensely hot spot that vaporizes the material, creating a dense, ionized vapor that results in extremely hard and durable coatings.

Understanding the Trade-offs

Choosing a PVD method involves balancing competing factors like film quality, deposition speed, and cost.

Sputtering: Precision and Adhesion

Sputtered films generally have excellent adhesion and density because the sputtered atoms arrive at the substrate with higher energy than evaporated atoms. However, the process can be slower than thermal evaporation.

Evaporation: Speed and Simplicity

Thermal evaporation is often faster and less complex, making it cost-effective for applications like decorative coatings or simple metal layers. The trade-off is often lower film density and adhesion compared to sputtering.

Arc Evaporation: Durability with a Catch

Arc evaporation produces some of the hardest and most resilient coatings available, making it the standard for cutting tools. Its main drawback is the potential formation of "macroparticles"—microscopic droplets of the source material that can embed in the film and create surface defects.

Specialized Methods for Advanced Needs

Techniques like Molecular Beam Epitaxy (MBE) and Pulsed Laser Deposition (PLD) offer unparalleled precision. MBE is a slow, ultra-high-vacuum evaporation technique for building perfect single-crystal layers in semiconductor manufacturing. PLD uses a laser to ablate the target, providing unique control over the composition of complex material films.

Making the Right Choice for Your Goal

Your application's primary requirement should guide your choice of PVD technique.

- If your primary focus is hard, wear-resistant coatings for tools: Arc Evaporation or Magnetron Sputtering are the industry-standard solutions.

- If your primary focus is high-purity, uniform optical or electronic films: Sputtering offers the best control over film density, uniformity, and purity.

- If your primary focus is rapid, cost-effective metallization: Thermal Evaporation is often the most efficient and economical choice.

- If your primary focus is cutting-edge materials research or semiconductor fabrication: Specialized techniques like MBE or PLD are necessary for their atomic-level precision.

Ultimately, selecting the right PVD technique is about matching the energy and characteristics of the deposition method to the desired properties of your final film.

Summary Table:

| Technique | Primary Energy Source | Key Advantage | Common Applications |

|---|---|---|---|

| Sputtering | Ion Bombardment | Excellent Adhesion & Density | Optical & Electronic Films |

| Thermal Evaporation | Resistive/Electron Beam Heating | High Speed & Simplicity | Decorative Coatings, Metallization |

| Arc Evaporation | High-Current Electric Arc | Extreme Hardness & Durability | Cutting Tools, Wear-Resistant Coatings |

Need to select the ideal PVD technique for your specific coating requirements? KINTEK specializes in lab equipment and consumables for precise thin-film deposition. Our experts can help you choose the right sputtering, evaporation, or arc system to achieve superior film adhesion, hardness, and purity for your R&D or production needs. Contact our team today to discuss your project!

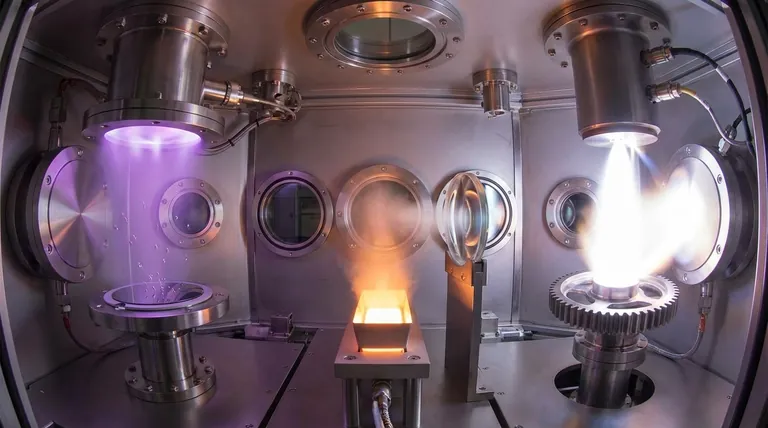

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is vacuum thermal evaporation? A Guide to High-Purity Thin Film Deposition

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is thermal evaporation technique thin film deposition? A Guide to Simple, Cost-Effective PVD