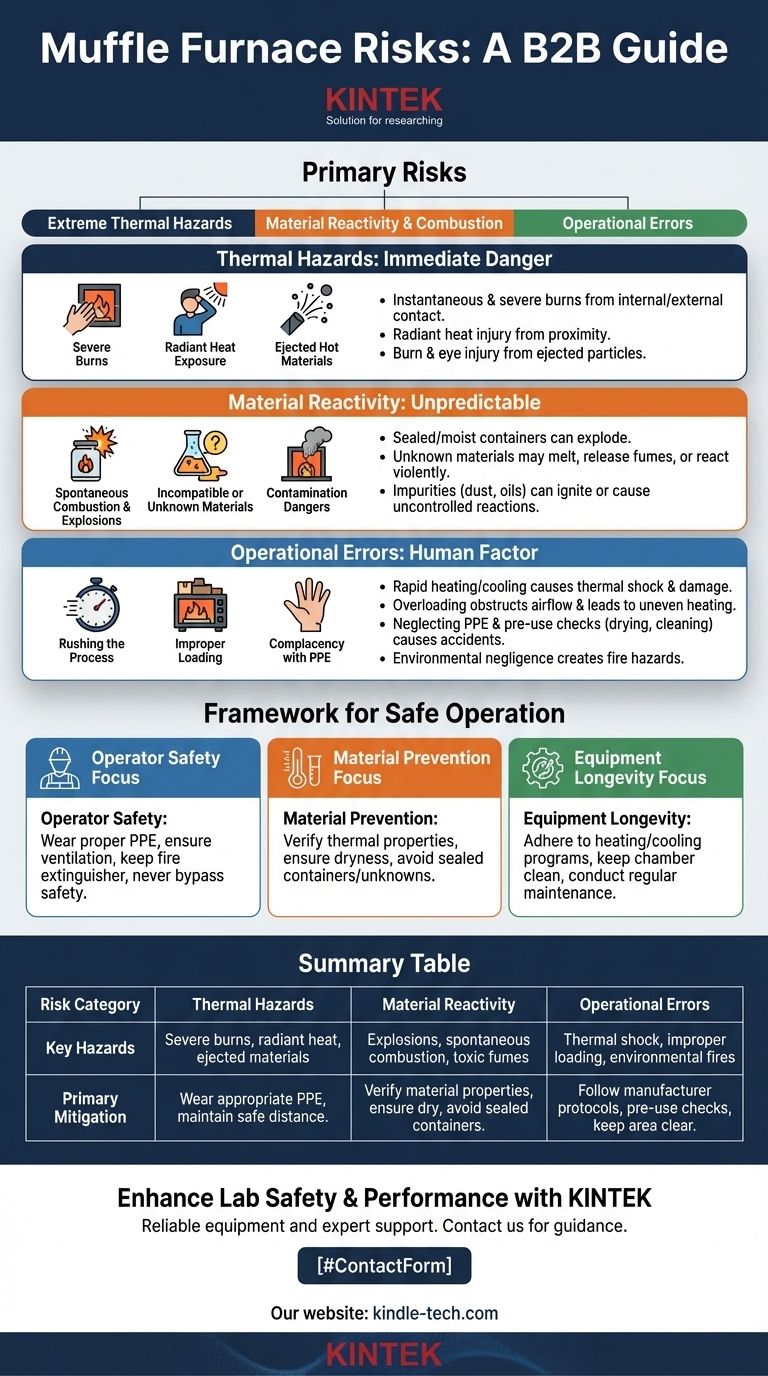

The primary risks of using a muffle furnace stem from three core areas: extreme thermal hazards causing severe burns, the potential for materials inside to explode or combust, and operational errors that create fire risks or damage the equipment. Safe operation is entirely dependent on understanding these dangers and adhering to strict safety protocols.

A muffle furnace is a powerful tool, but its high temperatures create a zero-tolerance environment for procedural errors. The greatest risks are not from the furnace itself, but from an operator's lack of awareness regarding material properties and safety discipline.

Thermal Hazards: The Most Immediate Danger

The most obvious and immediate risk is the extreme heat generated by the furnace, which can reach well over 1000°C. This heat presents a danger both directly and indirectly.

Risk of Severe Burns

Even brief contact with the internal components of an operating furnace will cause instantaneous and severe burns. The exterior casing also becomes extremely hot and can cause injury.

Radiant Heat Exposure

Simply being in close proximity to an open furnace door without proper thermal protection can lead to burns from radiant heat. This risk is often underestimated.

Ejected Hot Materials

If a sample reacts unexpectedly or shatters, hot particles can be forcefully ejected from the furnace opening, posing a burn and eye injury risk to anyone nearby and a fire risk to the surrounding area.

Material Reactivity: The Unpredictable Risk

The most volatile and unpredictable dangers arise from the materials placed inside the furnace. What is stable at room temperature can become hazardous at high heat.

Spontaneous Combustion and Explosions

Sealed containers, improperly dried samples containing moisture, or materials with a low ignition point can build pressure and explode. Some materials, like certain pellets, can spontaneously combust upon contact with the hot interior.

Incompatible or Unknown Materials

Placing any material in the furnace without knowing its melting or combustion point is a critical error. Materials that are not designed to withstand high temperatures can melt, release toxic fumes, or react violently.

Contamination Dangers

Impurities like dust, oils, or combustible fibers inside the furnace chamber can ignite or create an unintended furnace atmosphere, leading to uncontrolled reactions with the sample.

Understanding Common Pitfalls and Operational Errors

Many risks are introduced not by the equipment, but by human error and a failure to respect the furnace's operational principles.

Rushing the Process

Muffle furnaces require slow, controlled heating and cooling cycles. Attempting to heat the furnace too quickly or forcing a rapid cool-down can cause thermal shock, damaging the furnace's internal lining and potentially shattering the sample.

Improper Loading

Overloading the furnace or placing samples incorrectly can obstruct airflow and lead to uneven heating. This can ruin the process and, in some cases, contribute to a sample's unexpected reaction.

Neglecting Pre-Use Checks

Failing to ensure a sample is completely dry is a common cause of minor explosions from steam pressure. Likewise, failing to clean the furnace chamber of debris from previous runs invites contamination.

Complacency with PPE

Operators must wear appropriate Personal Protective Equipment (PPE) at all times. This includes heat-resistant gloves and safety goggles or a face shield. Assuming a quick task doesn't require PPE is a frequent cause of injury.

Environmental Negligence

Placing flammable liquids, paper, or other combustible materials anywhere near the furnace creates a significant fire hazard. The area around the unit must be kept clear.

A Framework for Safe Muffle Furnace Operation

To mitigate these risks, adopt a protocol-driven approach. Your choices should be dictated by your primary objective for each task.

- If your primary focus is operator safety: Always wear appropriate PPE, ensure the furnace has proper ventilation, keep a fire extinguisher nearby, and never bypass safety features.

- If your primary focus is preventing material reactions: Verify the thermal properties of every sample, ensure all samples are completely dry, and never place sealed containers or unknown substances inside the furnace.

- If your primary focus is equipment longevity and reliability: Adhere strictly to the manufacturer's heating and cooling programs, keep the furnace chamber clean, and conduct regular maintenance checks.

Ultimately, disciplined procedure and a thorough understanding of your materials are the definitive keys to operating a muffle furnace safely and effectively.

Summary Table:

| Risk Category | Key Hazards | Primary Mitigation |

|---|---|---|

| Thermal Hazards | Severe burns, radiant heat, ejected materials | Wear appropriate PPE (gloves, goggles), maintain safe distance |

| Material Reactivity | Explosions, spontaneous combustion, toxic fumes | Verify material properties, ensure samples are dry, avoid sealed containers |

| Operational Errors | Thermal shock, improper loading, environmental fires | Follow manufacturer protocols, conduct pre-use checks, keep area clear |

Ensure your laboratory operates with maximum safety and efficiency. The risks associated with muffle furnaces highlight the critical need for reliable equipment and expert support. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs. Our team can help you select the right furnace and provide guidance on safe operation protocols. Contact us today to discuss how we can enhance your lab's safety and performance.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Does casting change material properties? Understand the Microstructural Impact on Performance

- What are the environmental impacts of metal processing? A Guide to Sustainability and Solutions

- Why does melting require energy? Unlock the Science of Latent Heat and Phase Changes

- What temperature does steel liquify? Understanding the Melting Range for Your Applications

- Does heat capacity affect melting point? Unraveling the Key Differences in Thermal Properties