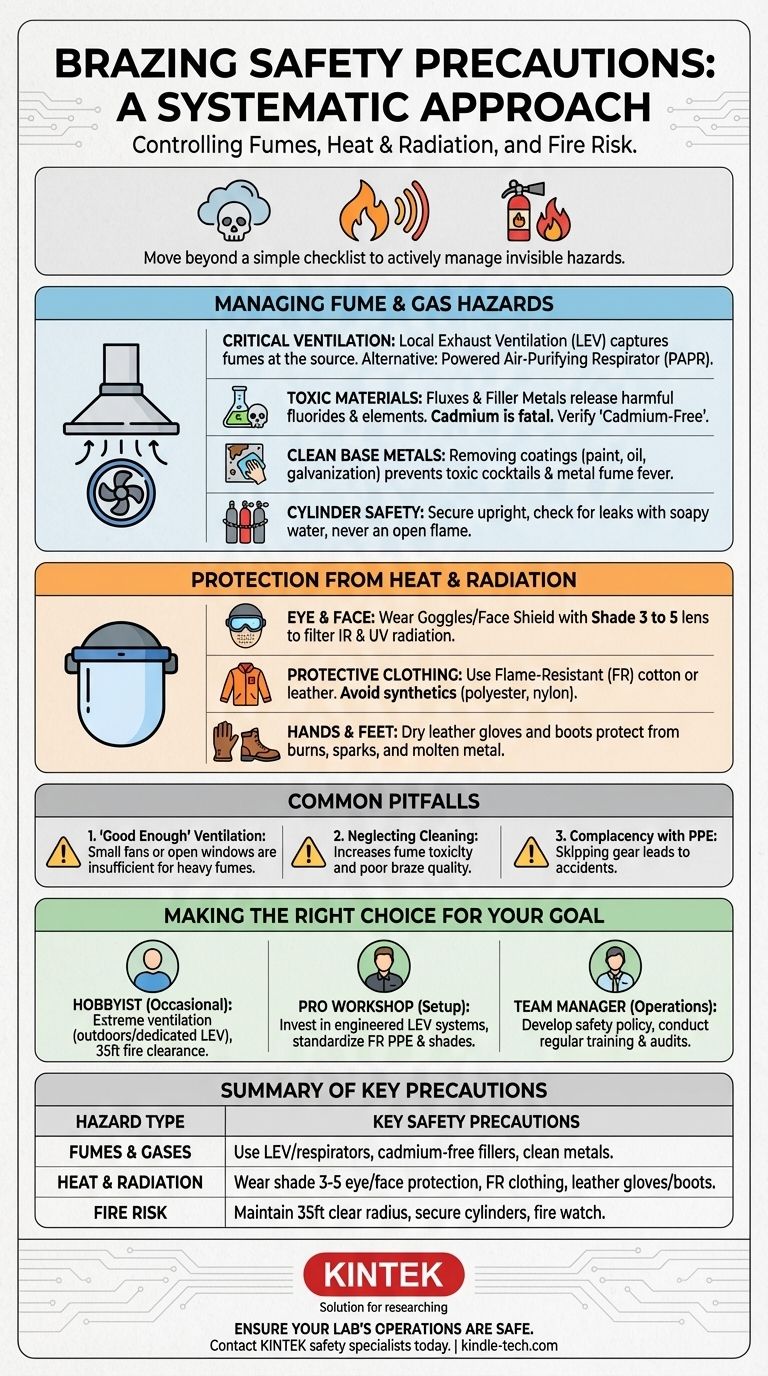

At its core, brazing safety is a systematic process of controlling three primary hazards: hazardous fumes, intense heat and radiation, and the risk of fire. The most critical precautions involve ensuring robust ventilation to remove toxic fumes at their source, wearing appropriate personal protective equipment (PPE) for eyes and skin, and meticulously preparing the workspace to eliminate all fire hazards.

Brazing is not merely "hot gluing" for metal; it's a chemical and thermal process that creates significant, often invisible, hazards. A truly safe operation moves beyond a simple checklist and adopts a mindset of actively managing fumes, radiation, and fire risk at all times.

Managing Fume and Gas Hazards

The most underestimated danger in brazing comes from the fumes and gases generated by the process. Inhaling these can cause both acute and chronic health problems.

The Critical Role of Ventilation

Simply opening a garage door is insufficient. Brazing requires local exhaust ventilation (LEV), which uses a hood and fan system to capture fumes directly at the source, pulling them away before they enter your breathing zone. If LEV is not feasible, a powered air-purifying respirator (PAPR) or supplied-air respirator is necessary.

Understanding Flux and Filler Metal Fumes

Brazing fluxes contain chemicals like fluorides that become airborne during heating. These are highly irritating to the eyes, nose, and lungs. Furthermore, some filler metals contain elements like zinc, copper, and historically, cadmium.

Cadmium, in particular, is extremely toxic, and inhaling its fumes can be fatal without immediate symptoms. Always verify your filler metal is "Cadmium-Free."

Dangers from Base Metal Coatings

The metal you are brazing must be perfectly clean. Heating base metals coated with paint, oil, grease, or plating (like galvanization) releases a cocktail of toxic substances. Lead-based paint is a severe hazard, and heating galvanized (zinc-coated) steel can cause metal fume fever, an illness with flu-like symptoms.

Gas Cylinder Safety

Always secure fuel and oxygen cylinders in an upright position and chain them to a wall or cart to prevent them from falling. When not in use, ensure the valve caps are on. Check for leaks at all connections using a soapy water solution; never use an open flame.

Personal Protection from Heat and Radiation

The visible hazards of heat and light radiation from the torch flame and hot metal require specific barriers.

Essential Eye and Face Protection

Brazing produces infrared (IR) and ultraviolet (UV) radiation that can permanently damage your eyes. Standard safety glasses are not enough. You must wear goggles or a face shield with lenses rated for brazing, typically a Shade 3 to 5, to filter this harmful radiation.

Proper Protective Clothing

Sparks and molten filler metal can cause severe burns. Wear durable, flame-resistant (FR) clothing, such as heavy cotton or leather. Never wear synthetic fabrics like polyester or nylon, as they can melt onto your skin. Keep cuffs and pockets buttoned.

Hand and Foot Protection

Dry, flame-resistant leather gloves are essential for handling hot materials and protecting from the torch. High-top leather boots provide the best protection for your feet against falling sparks or metal.

Understanding the Trade-offs and Common Pitfalls

Trusting in "common sense" alone is a frequent and dangerous mistake. Awareness of these common pitfalls is key to maintaining a safe environment.

"Good Enough" Ventilation is Never Enough

The most common pitfall is underestimating the fume hazard. A small fan across the room or an open window does not create a safe breathing zone. Fumes are often invisible and heavier than air, and they must be captured at the source.

Neglecting Base Metal Cleaning

Operators in a hurry may skip the crucial step of thoroughly cleaning the base metal. This not only results in a poor-quality braze joint but also significantly increases the volume and toxicity of the fumes produced.

Complacency with PPE

After performing a task many times, it's easy to become complacent and skip putting on a face shield or wearing proper FR clothing. This is when accidents happen. Treat every brazing operation with the same rigorous attention to safety.

Making the Right Choice for Your Goal

Implementing a safety protocol is not one-size-fits-all. It depends on your environment and the frequency of your work.

- If your primary focus is occasional hobbyist work: Prioritize extreme ventilation and fire prevention. Always move the work outside or use a dedicated LEV system, and rigorously clear a 35-foot radius of all flammable materials.

- If your primary focus is setting up a professional workshop: Invest in engineered solutions. Install a permanent, professionally designed LEV system and standardize the use of specific shade-rated face shields and FR clothing.

- If your primary focus is managing a team of operators: Develop and enforce a written safety policy. Conduct regular training on fume hazards, PPE use, and fire watch procedures, and perform periodic safety audits.

A disciplined approach to safety is what separates a professional from an amateur and ensures you can work effectively without risking your long-term health.

Summary Table:

| Hazard Type | Key Safety Precautions |

|---|---|

| Fumes & Gases | Use local exhaust ventilation (LEV), wear respirators, use cadmium-free filler metals, clean base metals thoroughly. |

| Heat & Radiation | Wear shade 3-5 eye/face protection, flame-resistant (FR) clothing, and leather gloves/boots. |

| Fire Risk | Maintain a clear 35-foot radius of flammables, secure gas cylinders, and have a fire watch. |

Ensure your lab's brazing operations are safe and efficient. Proper safety protocols are non-negotiable when working with high heat and hazardous materials. KINTEK specializes in providing reliable lab equipment and consumables that support safe workflows. Whether you need advice on setting up a safe brazing station or require high-quality materials, our experts are here to help. Contact our safety specialists today to discuss your laboratory's needs and how we can support your team's safety and success.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project