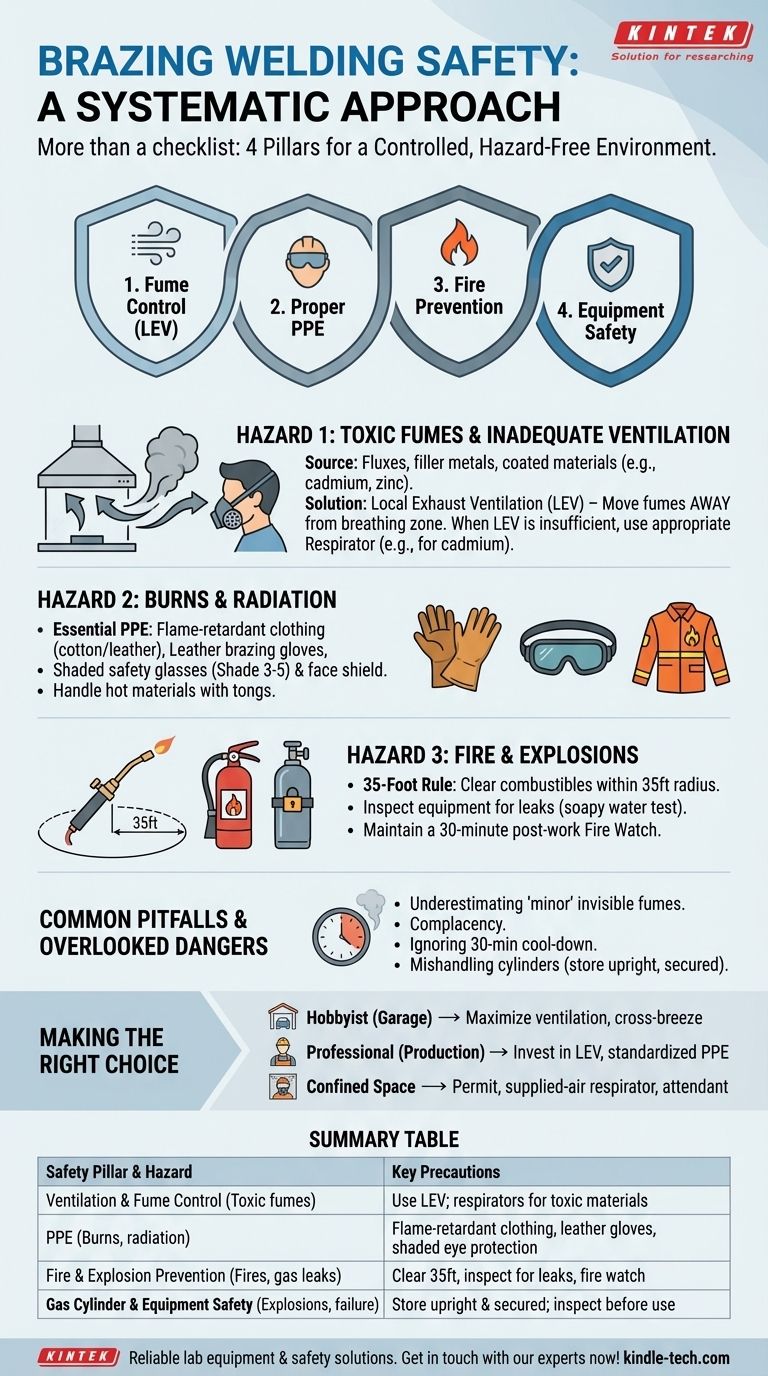

Effective brazing safety is a system, not just a checklist. The essential precautions revolve around four pillars: using proper Personal Protective Equipment (PPE) to guard against heat and radiation, ensuring robust ventilation to remove toxic fumes, meticulously preparing the work area to prevent fires, and correctly handling compressed gas cylinders and equipment.

The most critical, and often overlooked, danger in brazing is not the visible flame but the invisible fumes. Metals and fluxes release toxic substances when heated, making proper ventilation the single most important safety control you can implement.

Hazard 1: Toxic Fumes and Inadequate Ventilation

Brazing fumes can contain hazardous substances from the base metal, its coating, the filler metal, and the flux. Inhaling these can cause both short-term illness and long-term, irreversible health damage.

Understanding the Source of Fumes

The primary culprits are fluxes, which can release fluorides, and filler metals, which may contain cadmium, zinc, or other toxic elements. Heating coated or plated materials, such as galvanized steel (zinc) or cadmium-plated hardware, is especially dangerous.

The Critical Role of Ventilation

Never braze in a poorly ventilated area. General ventilation, like an open garage door, is rarely sufficient. The goal is to move the fumes away from your breathing zone before you can inhale them.

Local Exhaust Ventilation (LEV)

The best practice is Local Exhaust Ventilation (LEV). This involves using a fume extractor or snorkel with a capture hood positioned close to the work, pulling the fumes away at the source.

When to Use a Respirator

If adequate LEV cannot be established, particularly in confined spaces or when working with known toxic materials like cadmium, a respirator is required. The type of respirator must be matched to the specific fume hazard present.

Hazard 2: Burns and Radiation

The high temperatures involved in brazing present an obvious risk of severe burns from the flame, heated base metal, and hot filler material.

Essential Personal Protective Equipment (PPE)

Your non-negotiable PPE includes flame-retardant clothing, often made of cotton or leather, and leather brazing gloves. Synthetic materials like polyester can melt and cause severe burns.

Eye and Face Protection

Brazing produces infrared (IR) radiation that can damage your eyes. Always wear safety glasses or goggles with an appropriate shade rating (typically Shade 3-5 for brazing). A face shield provides additional protection from sparks and spatter.

Handling Hot Materials

Remember that the workpiece remains dangerously hot long after the flame is removed. Use pliers or tongs to handle the piece and place it on a fire-resistant surface to cool.

Hazard 3: Fire and Explosions

The combination of an open flame and highly flammable fuel gases creates a significant fire and explosion risk.

Prepare the Work Area

Follow the "35-foot rule": clear all combustible materials—including wood, paper, rags, and flammable liquids—within a 35-foot radius of the brazing operation. If combustibles cannot be moved, cover them with fire-resistant blankets.

Inspect Your Equipment

Before every use, inspect your hoses, regulators, and torch for damage or leaks. A common method is to apply a soapy water solution to connections; bubbling indicates a gas leak that must be fixed immediately.

The Necessity of a Fire Watch

For any significant brazing job, have a coworker act as a "fire watch." Their only job is to scan the area for sparks and smoldering fires, both during the work and for at least 30 minutes after its completion. Always keep a suitable fire extinguisher within immediate reach.

Common Pitfalls and Overlooked Dangers

Building a true safety culture means understanding the subtle mistakes that lead to accidents.

Underestimating "Minor" Fumes

A common mistake is assuming that a small amount of smoke is harmless. The most dangerous fumes, like those from cadmium, can be nearly invisible and have no odor, yet they are extremely toxic.

Complacency in Familiar Environments

Performing the same task repeatedly can lead to complacency. Treat every single brazing operation with the same rigorous safety preparation, from equipment inspection to clearing the area.

Ignoring Post-Work Hazards

Fires often start from a small, smoldering spark long after the work has finished. The 30-minute cool-down watch is not optional; it is a critical final step in the process.

Mishandling Gas Cylinders

Compressed gas cylinders must always be stored upright and securely chained to a wall or cart to prevent them from falling. A damaged cylinder valve can turn the cylinder into a high-speed projectile.

Making the Right Choice for Your Goal

Your specific environment dictates how these principles are applied.

- If your primary focus is hobbyist work in a garage: Prioritize maximum ventilation by opening all doors and using fans for cross-breeze, and be absolutely meticulous about clearing flammables.

- If your primary focus is a professional production environment: Invest in engineering controls like Local Exhaust Ventilation (LEV) at every brazing station and enforce strict, standardized PPE rules.

- If your primary focus is brazing in confined spaces: This is a high-risk task that requires a formal permit, a supplied-air respirator, continuous air monitoring, and a dedicated attendant outside the space.

- If you are working with unknown or coated metals: Assume the worst-case scenario. Use the highest level of ventilation and respiratory protection until you can confirm the material composition.

A disciplined and consistent approach to safety transforms brazing from a potential hazard into a predictable and controlled process.

Summary Table:

| Safety Pillar | Key Precautions | Common Hazards Addressed |

|---|---|---|

| Ventilation & Fume Control | Use Local Exhaust Ventilation (LEV); wear respirators for toxic materials like cadmium. | Toxic fumes from fluxes, filler metals, and coated materials. |

| Personal Protective Equipment (PPE) | Flame-retardant clothing, leather gloves, and shaded eye protection (Shade 3-5). | Severe burns, IR radiation, sparks, and spatter. |

| Fire & Explosion Prevention | Clear combustibles within 35 feet; inspect equipment for leaks; maintain a fire watch. | Fires from open flames, gas leaks, and sparks. |

| Gas Cylinder & Equipment Safety | Store cylinders upright and secured; inspect hoses/regulators before each use. | Cylinder explosions, gas leaks, and equipment failure. |

Ensure your brazing operations are safe and efficient with the right equipment.

At KINTEK, we specialize in providing reliable lab equipment and consumables tailored to your laboratory's needs. Whether you require fume extraction systems, safety PPE, or durable brazing tools, our solutions are designed to enhance your safety protocols and workflow.

Contact us today to discuss how we can support your brazing safety goals and help you create a controlled, hazard-free environment.

Get in touch with our experts now!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What is the function of alumina tubes and alumina wool in a pyrolysis furnace? Optimize Your Biochar Production Quality

- What are the hazards of a tube furnace? Beyond the Obvious Burn Risks

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere