The primary safety precautions for a power press involve a systematic combination of engineered guards, strict energy control procedures, and comprehensive operator training. These layers work together to prevent an operator's hands or body from ever being in the point of operation during the machine's stroke. The most critical measures include physical barrier guards, presence-sensing devices like light curtains, two-hand controls, and a robust Lockout/Tagout (LOTO) program for all maintenance and setup tasks.

The core principle of power press safety is not to rely on human behavior or a single device, but to create redundant systems that make it physically impossible for an operator to be injured. True safety is achieved when the machine's design and procedures eliminate the possibility of human error leading to a catastrophic accident.

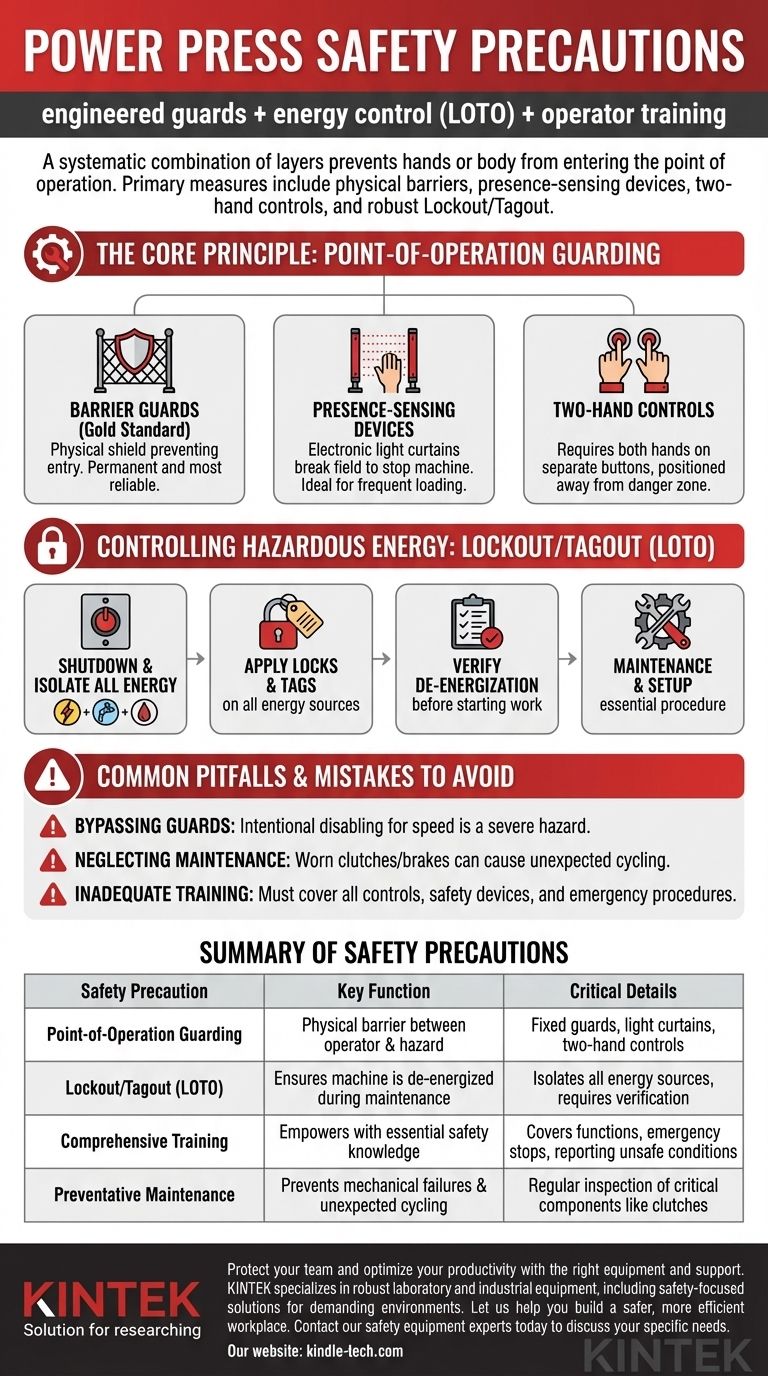

The Core Principle: Point-of-Operation Guarding

The "point of operation" is where the die performs work on the material, and it is the single most dangerous part of the press. Guarding this area is not optional; it is the foundation of power press safety.

Why Guarding is Non-Negotiable

A power press ram moves with immense force and speed. Human reaction time is far too slow to pull back from the danger zone once a stroke has been initiated. Guarding provides a reliable, engineered barrier between the operator and the hazard.

Barrier Guards (The Gold Standard)

A fixed barrier guard is a physical shield that prevents entry into the danger zone. It is considered the most reliable method because it is permanent and does not require any action from the operator to be effective.

Presence-Sensing Devices

Light curtains are electronic guards that project a field of infrared light in front of the point of operation. If any object, such as a hand, breaks this field while the press is in its hazardous cycle, the machine immediately stops. These are ideal for operations requiring frequent parts loading and unloading.

Two-Hand Controls

This method requires the operator to use both hands to press separate buttons simultaneously to activate the press stroke. These controls are positioned far enough away from the die area that the operator cannot move their hands into the danger zone before the stroke is completed.

Controlling Hazardous Energy: Lockout/Tagout (LOTO)

A surprising number of power press injuries occur when the machine is not in active production. LOTO is a formal procedure to ensure a machine is completely de-energized and cannot be started up unexpectedly during service or maintenance.

The Purpose of LOTO

LOTO is essential for tasks like die changes, routine maintenance, clearing jams, and repairs. It prevents a catastrophic accident that could be caused by another person starting the machine while someone is working on it.

Isolating All Energy Sources

Effective LOTO goes beyond the main electrical disconnect. It requires isolating and dissipating all forms of hazardous energy, including pneumatic (compressed air) and hydraulic pressure, which can also cause machine movement.

The Lockout Procedure

A proper LOTO procedure involves notifying affected employees, shutting down the machine normally, isolating all energy sources, applying individual locks and tags, and—most critically—verifying that the machine is truly de-energized before beginning work.

Common Pitfalls and Mistakes to Avoid

Implementing safety hardware is only part of the solution. Avoiding common oversights and dangerous assumptions is critical to building a truly safe environment.

Bypassing or Disabling Guards

The most frequent cause of severe injury is the intentional disabling of safety devices. Operators or maintenance staff may bypass a guard to speed up a process or make a task "easier," which completely negates the machine's built-in protection. This practice must be strictly prohibited.

Neglecting Press Maintenance

A worn clutch or brake mechanism can cause the press to "repeat," or cycle unexpectedly, even after the operator has released the controls. A rigorous, documented maintenance and inspection program is a critical safety precaution to prevent mechanical failures.

Inadequate Training

Simply showing an operator the "on" button is not training. Proper training covers the function of every control and safety device on their specific press, LOTO procedures, emergency stop protocols, and empowers them to stop work immediately if they notice any unsafe condition.

Making the Right Choice for Your Goal

Implementing a robust safety program requires a commitment from every level of the organization.

- If your primary focus is operating the machine: Your duty is to perform a pre-shift inspection of all safety devices, never bypass a guard for any reason, and immediately report any malfunction to your supervisor.

- If your primary focus is engineering or supervision: Your goal is to ensure the correct type of guarding is used for every specific job, that LOTO procedures are strictly enforced, and that all training is kept current and is fully understood.

- If your primary focus is managing the facility: Your responsibility is to cultivate a culture where safety is valued above production speed, investing in modern safety equipment and comprehensive preventative maintenance programs.

A proactive and multi-layered approach transforms a power press from an inherent hazard into a predictable and highly productive tool.

Summary Table:

| Safety Precaution | Key Function | Critical Details |

|---|---|---|

| Point-of-Operation Guarding | Creates a physical barrier between the operator and the hazard. | Includes fixed barrier guards, light curtains, and two-hand controls. |

| Lockout/Tagout (LOTO) | Ensures machine is de-energized during maintenance and setup. | Isolates all energy sources (electrical, pneumatic, hydraulic) and requires verification. |

| Comprehensive Training | Empowers operators and maintenance staff with essential safety knowledge. | Covers device functions, emergency stops, and reporting unsafe conditions. |

| Preventative Maintenance | Prevents mechanical failures that can cause unexpected machine cycling. | Regular inspection of critical components like clutches and brakes is mandatory. |

Protect your team and optimize your productivity with the right equipment and support.

KINTEK specializes in providing robust laboratory and industrial equipment, including safety-focused solutions for demanding environments. Our expertise ensures you have reliable tools that meet the highest safety standards.

Let us help you build a safer, more efficient workplace.

Contact our safety equipment experts today to discuss your specific needs and how we can support your operational goals.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What size are extrusion pellets? Mastering Pellet Geometry for Optimal Extrusion Performance

- What is the maximum psi for a hydraulic press? Understand Tonnage, Not Just Pressure

- How do you make IR pellets? A Step-by-Step Guide to Flawless FTIR Sample Preparation

- What scientific principle governs the operation of a hydraulic press? Master Pascal’s Law for Force Multiplication

- Why is my hydraulic press not working? A Step-by-Step Guide to Diagnose & Fix Common Issues

- What materials are used in rolling technique? Shaping Metals from Steel to Precious Alloys

- Why was the hydraulic press invented? To Solve the Industrial Revolution's Force Problem

- What is metal forming with a hydraulic press? Harnessing Immense Force for Precision Shaping