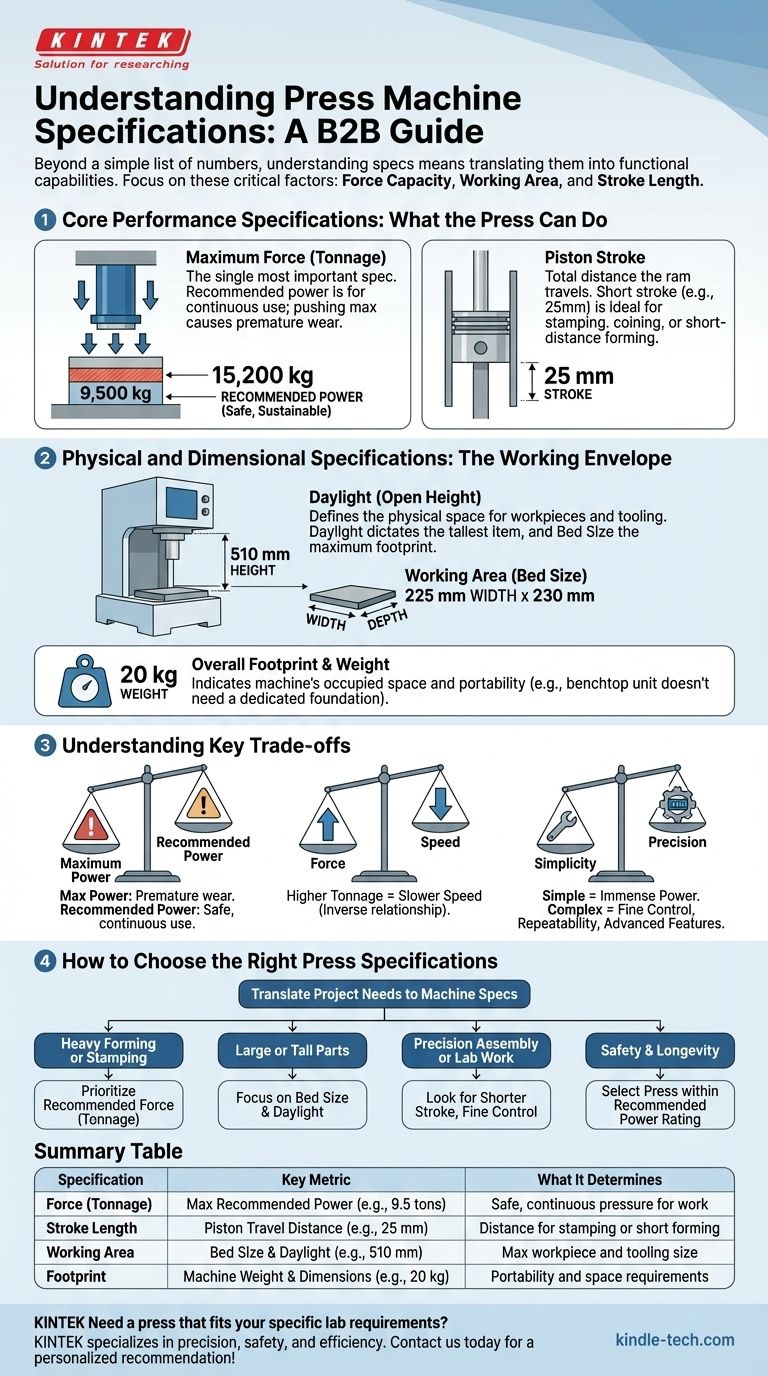

Understanding the specifications of a press machine requires looking beyond a simple list of numbers. Because presses vary from small benchtop units to massive industrial machines, their specifications differ dramatically based on their type and intended use. The key is to understand what each specification means for the work you intend to do.

The most critical specifications of a press are not its physical dimensions, but its force capacity (tonnage), working area (daylight and bed size), and stroke length. These three factors directly determine the size of the parts you can work on and the operations you can perform.

Core Performance Specifications: What the Press Can Do

The primary function of any press is to apply force. Its performance specifications define how much force it can apply and how it delivers that action.

Maximum Force (Tonnage)

This is the single most important specification. It measures the maximum pressure the press can exert and is often expressed in kilograms, pounds, or tons.

The example specifications list a maximum allowed power of 15,200 kg (approximately 15.2 metric tons) and a maximum recommended power of 9,500 kg (9.5 metric tons). This distinction is critical for safety and machine longevity.

Piston Stroke

The stroke is the total distance the moving ram or piston can travel from its fully retracted to its fully extended position.

A short stroke, like the 25 mm listed in the example, is common for operations like stamping, coining, or short-distance forming where high force is needed over a minimal distance.

Physical and Dimensional Specifications: The Working Envelope

These specifications define the physical space you have to work with, determining the maximum size of the workpiece and tooling (dies) that the press can accommodate.

Daylight (or Open Height)

Daylight refers to the maximum vertical distance between the ram and the press bed when the stroke is fully up. It dictates the tallest item that can fit inside the press.

The example's listed height of 510 mm (with a low spindle) likely represents its maximum daylight, providing the total vertical working room.

Working Area (Bed Size)

The bed is the flat, stationary surface upon which the workpiece and lower die are mounted. Its width and depth determine the maximum footprint of your project.

While not explicitly listed as "bed size," the example's width of 225 mm and depth of 230 mm indicate the machine's overall footprint, which constrains the size of the material you can place within it.

Overall Footprint and Weight

These dimensions tell you how much physical space the machine will occupy in your workshop and whether it requires special mounting.

A machine with a weight of 20 kg, like the one specified, is a small, portable benchtop unit that does not require a dedicated foundation.

Understanding the Key Trade-offs

Choosing a press involves balancing competing factors. Understanding these trade-offs is essential for selecting the right tool for the job.

Maximum vs. Recommended Power

Consistently operating a press at its absolute maximum allowed force will cause premature wear on its frame, seals, and hydraulic system.

The recommended power is the safe, sustainable limit for continuous, everyday use. Pushing beyond this should only be done intermittently, if at all.

Force vs. Speed

In most hydraulic systems, there is an inverse relationship between force and speed. A press designed to deliver extremely high tonnage will often move more slowly than a lower-tonnage press with a comparable power source.

Simplicity vs. Precision

A simple, manually operated press provides immense power but may lack the fine control, repeatability, and advanced features (like pressure holding or programmable cycles) of more complex, automated systems.

How to Choose the Right Press Specifications

Translate your project's needs into machine specifications to make an informed decision.

- If your primary focus is heavy forming or stamping: Prioritize the maximum recommended force (tonnage) to ensure the press can perform the work without strain.

- If your primary focus is working with large or tall parts: Focus on the bed size and daylight, ensuring your workpiece and tooling will fit comfortably within the working envelope.

- If your primary focus is precision assembly or lab work: Look for a press with a shorter stroke and features that allow for fine control over force and ram position.

- If your primary focus is safety and longevity: Always select a press where your typical working force falls comfortably within the manufacturer's recommended power rating.

By translating these numbers into functional capabilities, you can confidently select a machine that serves as a tool, not a limitation.

Summary Table:

| Specification | Key Metric | What It Determines |

|---|---|---|

| Force (Tonnage) | Maximum Recommended Power (e.g., 9.5 tons) | Maximum pressure the press can safely exert for continuous work |

| Stroke Length | Piston Travel Distance (e.g., 25 mm) | Distance the ram can move; ideal for stamping or short-distance forming |

| Working Area | Bed Size & Daylight (e.g., 510 mm height) | Maximum size of workpiece and tooling that can fit in the press |

| Footprint | Machine Weight & Dimensions (e.g., 20 kg) | Portability and space requirements for your lab or workshop |

Need a press that fits your specific lab requirements? KINTEK specializes in lab equipment and consumables, offering a range of press machines tailored for precision, safety, and efficiency. Whether you need high tonnage for heavy forming or a compact benchtop unit for assembly, our experts can help you select the right specifications for your workflow. Contact us today to discuss your project and get a personalized recommendation!

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Double Plate Heating Press Mold for Lab

People Also Ask

- How does a laboratory hydraulic hot press ensure the quality of PHBV/natural fiber composites? Expert Guide

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- What is the purpose of applying high pressure in dry cathode preparation? Achieve Peak Solid-State Battery Density

- What is the purpose of using a laboratory hydraulic press for nanocomposites? Ensure Precise Material Characterization