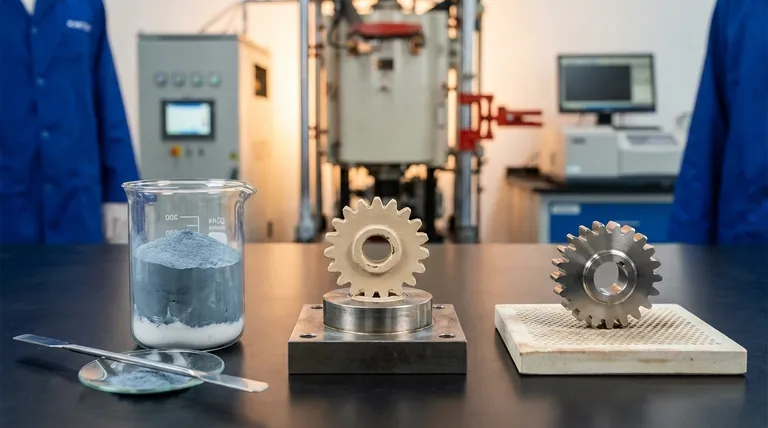

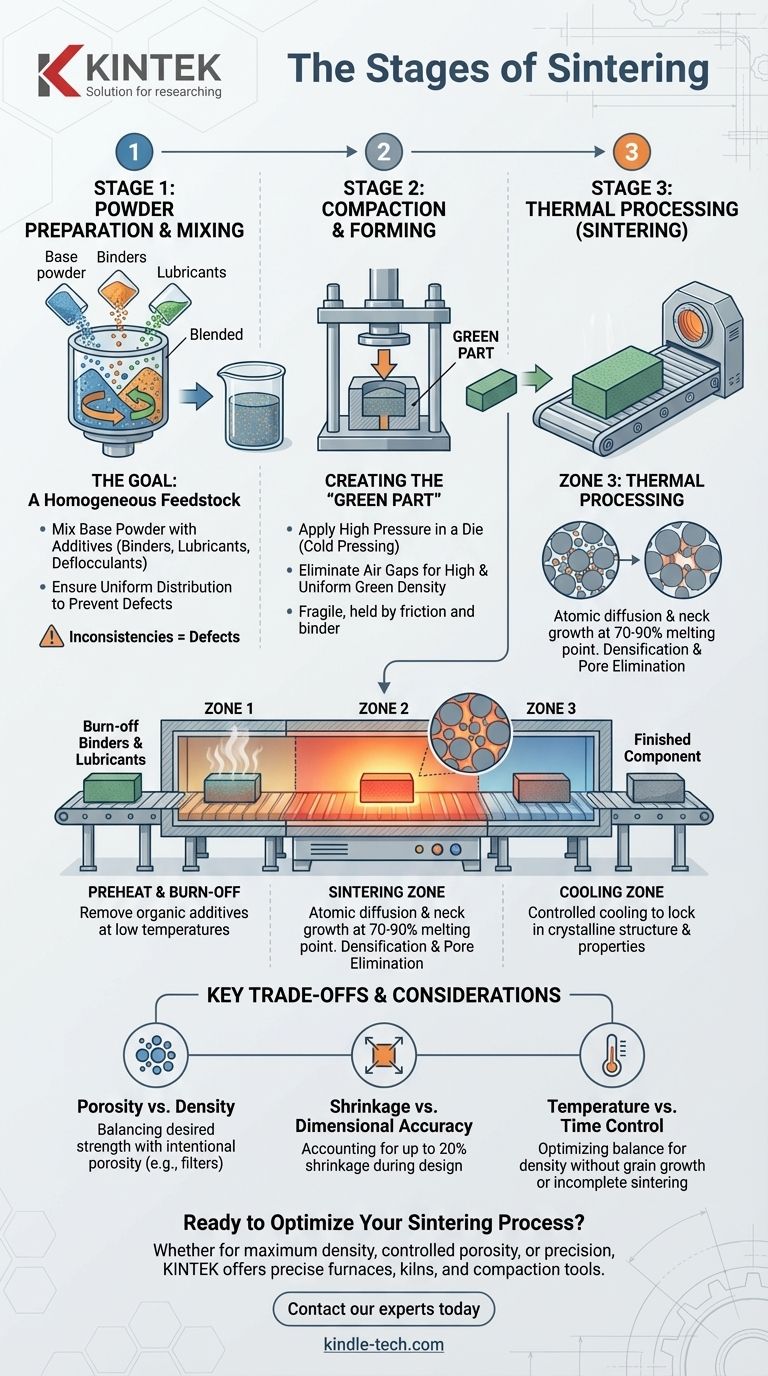

At its core, the sintering process consists of three fundamental stages: preparing and mixing a base powder, compacting that powder into a preliminary shape, and applying a precise thermal cycle to fuse the particles into a solid, dense object. This transforms a loose collection of grains into a finished component with specific mechanical properties.

Sintering is not about melting. It is a sophisticated process of transforming a fragile, compressed powder shape (a "green part") into a strong, unified mass by using heat to encourage atoms to migrate and bond across particle boundaries, causing the part to densify and solidify.

Stage 1: Powder Preparation and Mixing

The quality of the final sintered part is determined before any heat is ever applied. The first stage is entirely focused on creating a perfectly uniform starting material.

The Goal: A Homogeneous Feedstock

The primary goal is to create a homogenous mixture. If different materials are used, they must be distributed evenly to ensure the final part has consistent properties throughout.

Any inconsistencies in the starting powder, such as clumps or unevenly mixed additives, will translate directly into defects like weak spots or warping in the final product.

Key Additives

To facilitate the process, several other materials are often mixed with the primary ceramic or metal powder:

- Binders: These are organic "glues" that help hold the powder particles together in the compacted shape before the final heating.

- Lubricants: These agents reduce friction between particles and with the mold walls during the compaction stage, allowing for more uniform density.

- Deflocculants: In wet processes where the powder is mixed into a slurry, these prevent the particles from clumping together.

Stage 2: Compaction and Forming

Once the powder is prepared, it must be formed into the desired shape. This is a mechanical process designed to get the individual particles as close to one another as possible.

Creating the "Green Part"

The powder is loaded into a die or mold and subjected to high pressure. This process, often called cold pressing, forces the particles together, eliminating large air gaps (voids).

The resulting object is known as a "green part." At this stage, it is solid enough to be handled but is extremely fragile, held together only by mechanical friction and the weak action of the binder.

The Importance of Density

The main objective of compaction is to achieve a high and uniform "green density." The denser the green part, the less shrinkage will occur during sintering and the easier it will be to achieve a strong, non-porous final component.

Stage 3: Thermal Processing (Sintering)

This is the critical transformation stage where the fragile green part is converted into a durable, solid object. It does not happen all at once but is a controlled process with distinct thermal zones, typically within a specialized furnace or kiln.

Zone 1: Preheat and Burn-Off

As the part is slowly heated, the first objective is to remove the organic additives from the mixing stage. The binders and lubricants are carefully burned away at low temperatures.

This must be done gradually to allow the gases to escape without building up pressure and cracking the part.

Zone 2: The Sintering Zone

This is the heart of the process. The temperature is raised to a point significantly below the material's melting point—typically around 70-90% of it.

At this high temperature, the atoms at the boundaries of the individual particles become highly agitated and begin to diffuse across to neighboring particles. This atomic migration creates small "necks" of solid material where particles touch. As the process continues, these necks grow, pulling the particles closer, shrinking the part, and systematically eliminating the pores between them.

Zone 3: The Cooling Zone

After holding at the sintering temperature for a set time, the part is moved into a cooling zone. Controlled cooling is just as important as controlled heating.

Cooling too quickly can induce thermal shock, causing cracks and internal stresses. This final step locks in the material's final crystalline structure and, consequently, its mechanical properties like hardness and strength.

Understanding the Key Trade-offs

Sintering is a balancing act between multiple factors. Understanding these trade-offs is crucial for process control and achieving the desired outcome.

Porosity vs. Density

While the goal is often to eliminate porosity, achieving 100% density is difficult. Some residual porosity almost always remains. In some applications, like self-lubricating bearings or filters, this porosity is intentional and desirable. The process is tuned to control the final pore volume.

Shrinkage and Dimensional Accuracy

As pores are eliminated and the part densifies, it will shrink. This shrinkage can be significant (up to 20% by volume) and must be precisely calculated and accounted for in the initial design of the compaction mold.

Temperature and Time Control

The relationship between temperature and time is critical. A lower sintering temperature can be compensated for with a longer hold time, and vice versa. However, finding the optimal balance is key to achieving the desired density without risking grain growth, which can degrade mechanical properties, or incomplete sintering, which results in a weak part.

Making the Right Choice for Your Goal

The parameters of each stage are adjusted based on the intended function of the final component.

- If your primary focus is maximum density and strength: You will use high compaction pressures and optimize the sintering temperature and hold time to eliminate as much porosity as possible.

- If your primary focus is creating a porous component (e.g., a filter): You will use lower compaction pressures and a shorter, lower-temperature sintering cycle to fuse the particle contact points without causing full densification.

- If your primary focus is high-precision, complex shapes: You must prioritize a uniform powder mix and a precise mold design that accurately predicts and compensates for shrinkage during the thermal cycle.

Ultimately, mastering sintering is about controlling a journey of atomic-level bonding to engineer a material's final form and function.

Summary Table:

| Stage | Key Objective | Key Activities & Considerations |

|---|---|---|

| 1. Powder Preparation & Mixing | Create a homogeneous feedstock for consistent properties. | - Mixing base powder with additives (binders, lubricants). - Ensuring uniform distribution to prevent defects. |

| 2. Compaction & Forming | Form a high-density "green part" for minimal shrinkage. | - Applying high pressure in a die (cold pressing). - Achieving uniform green density for handling and sintering. |

| 3. Thermal Processing (Sintering) | Transform the fragile green part into a strong, solid object. | - Burn-Off: Removing organic additives. - Sintering Zone: Atomic diffusion and neck growth. - Cooling: Controlled cooling to lock in properties. |

Ready to Optimize Your Sintering Process?

Whether your goal is maximum density for strength, controlled porosity for filtration, or precision for complex shapes, the right lab equipment is critical. KINTEK specializes in providing the precise furnaces, kilns, and compaction tools needed to master each stage of sintering.

Contact our experts today to discuss how our solutions can help you achieve superior material properties and consistent results for your laboratory needs.

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What is a sputtering machine? A Guide to High-Quality Thin Film Deposition

- What is sputtering technology? A Guide to Precision Thin Film Deposition

- What are the challenges of welding stainless steel? Overcome Warping, Sensitization, and Contamination