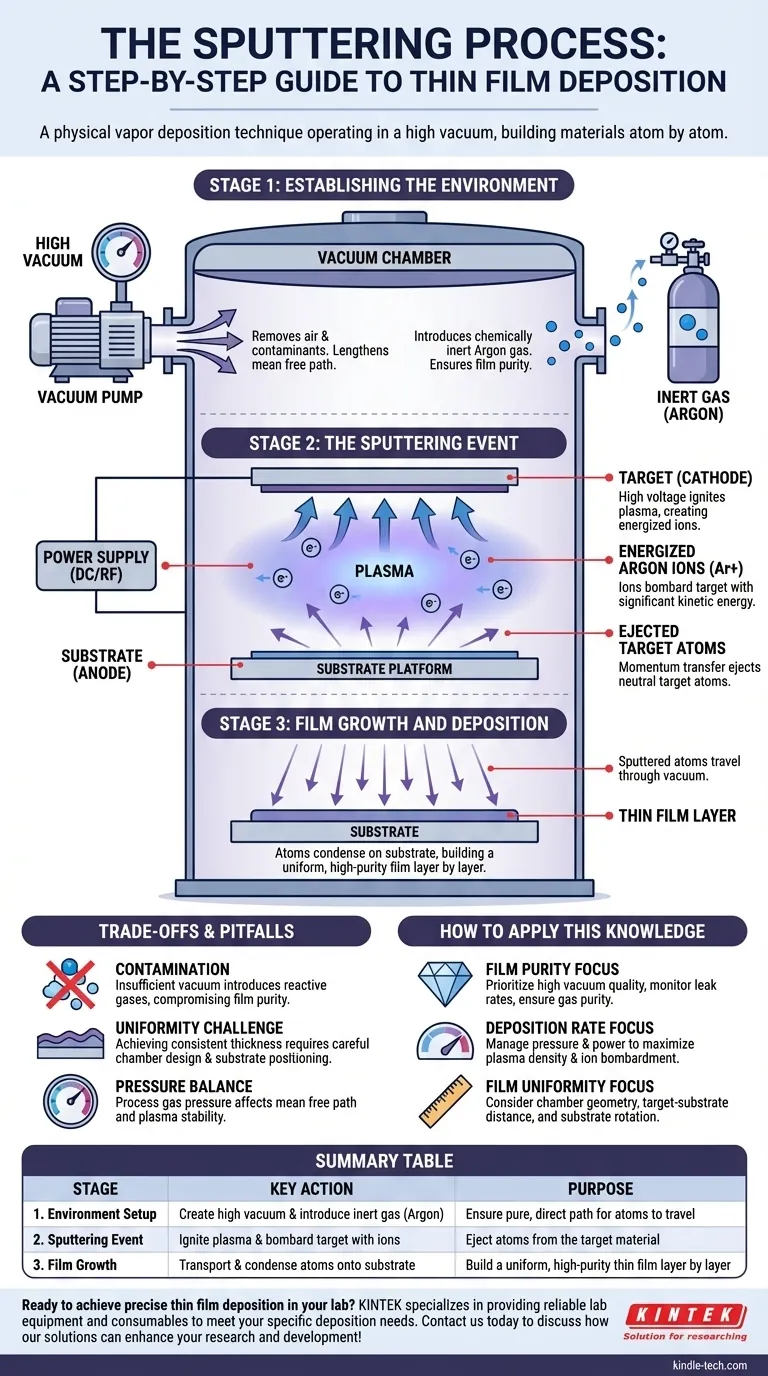

In essence, the sputtering process is a physical vapor deposition technique that operates in a high vacuum. It uses energetic ions from a plasma to bombard a source material, known as the target, which dislodges atoms. These liberated atoms then travel through the vacuum chamber and deposit onto a substrate, building a new, high-purity thin film layer by layer.

Sputtering is not a chemical reaction but a physical process of momentum transfer, akin to a microscopic game of billiards. By creating a high-vacuum environment and energizing a plasma, we can precisely control the bombardment of a target to build a new material, atom by atom.

Stage 1: Establishing the Environment

The success of the entire sputtering process depends on meticulously preparing the chamber environment before any deposition occurs.

Creating the High Vacuum

The first and most critical step is creating a vacuum inside the process chamber using a vacuum pump. Air and other contaminants are removed.

This vacuum is non-negotiable because it dramatically lengthens the mean free path of particles. This ensures that atoms sputtered from the target can travel directly to the substrate without colliding with unwanted air or water molecules.

Introducing the Process Gas

Once a sufficient vacuum is achieved, a controlled amount of a high-purity, inert gas is introduced into the chamber.

Argon is the most common choice. Because it is chemically inert, it will not react with the target material, ensuring the deposited film is composed purely of the target's atoms.

Stage 2: The Sputtering Event

This stage is the core of the process, where the physical mechanism of sputtering takes place. It is a rapid, self-sustaining chain of events.

Igniting the Plasma

A high voltage is applied to the target material, which acts as a cathode (negative electrode). This powerful electric field energizes the inert gas atoms.

This energy strips electrons from the gas atoms, creating a mixture of free electrons and positively charged ions. This energized, ionized gas is known as a plasma.

Ion Bombardment

The negatively charged target violently attracts the newly formed, positively charged argon ions from the plasma.

These ions accelerate toward the target, striking its surface with significant kinetic energy. This is the "bombardment" phase.

Ejecting Target Atoms

When an energetic ion collides with the target, it transfers its momentum to the target's atoms. If the energy transfer is sufficient, it will knock one or more atoms completely free from the target's surface.

These ejected, neutral atoms are the material that will ultimately form the thin film.

Stage 3: Film Growth and Deposition

The final stage involves the journey of the ejected atoms and their accumulation on the substrate.

Transport Through the Vacuum

The sputtered atoms travel in a straight line from the target through the vacuum-filled chamber. The quality of the vacuum is critical here to prevent these atoms from colliding with other particles, which would scatter them and result in a non-uniform film.

Condensation on the Substrate

When the sputtered atoms reach the surface of the substrate (the material being coated), they condense and stick.

Over time, this continuous bombardment of atoms builds up on the substrate, layer by layer, forming a dense and uniform thin film.

Understanding the Trade-offs and Pitfalls

While powerful, sputtering is a process of precision where small deviations can have significant consequences.

The Constant Enemy: Contamination

An insufficient vacuum is the primary source of failure. If reactive gases like oxygen or water vapor remain in the chamber, they can react with the sputtered atoms and become incorporated into the growing film, compromising its purity and performance.

The Challenge of Uniformity

Achieving a perfectly uniform film thickness across a large substrate is challenging. It requires careful design of the chamber, the positioning of the substrate relative to the target, and sometimes substrate rotation to average out any inconsistencies in the flux of sputtered atoms.

The Pressure Balance

The pressure of the process gas (e.g., argon) is a critical variable. Too high a pressure reduces the mean free path, causing sputtered atoms to scatter. Too low a pressure can make it difficult to sustain a stable plasma, leading to a very low deposition rate.

How to Apply This Knowledge

Understanding these fundamental steps transforms sputtering from a "black box" into a predictable engineering tool.

- If your primary focus is film purity and quality: Your first priority must be the quality of the vacuum. Monitor leak rates and ensure the purity of the process gas.

- If your primary focus is deposition rate: You must manage the relationship between process gas pressure and applied power to maximize plasma density and, therefore, the ion bombardment rate.

- If your primary focus is film uniformity: You must consider the geometry of the chamber, the target-to-substrate distance, and the potential need for substrate rotation.

By mastering these core stages, you gain direct control over the properties and quality of the final material.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Environment Setup | Create high vacuum & introduce inert gas (Argon) | Ensure pure, direct path for atoms to travel |

| 2. Sputtering Event | Ignite plasma & bombard target with ions | Eject atoms from the target material |

| 3. Film Growth | Transport & condense atoms onto substrate | Build a uniform, high-purity thin film layer by layer |

Ready to achieve precise thin film deposition in your lab? The sputtering process is key to creating high-quality coatings for semiconductors, optics, and research applications. KINTEK specializes in providing reliable lab equipment and consumables to meet your specific deposition needs.

Contact us today to discuss how our solutions can enhance your research and development!

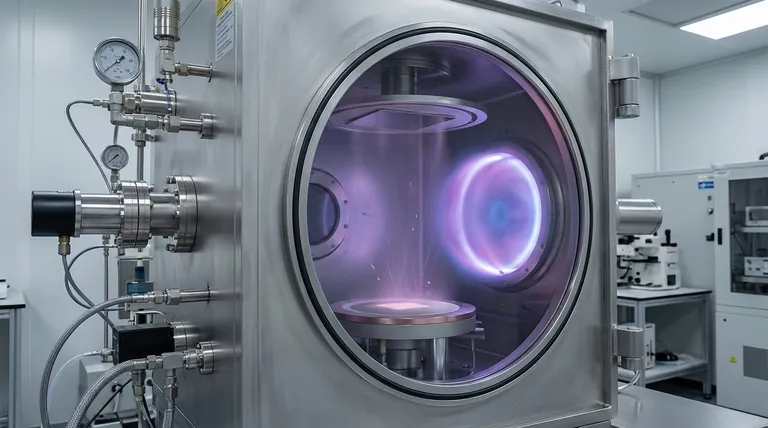

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Evaporation Boat for Organic Matter

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications