Fundamentally, the Chemical Vapor Deposition (CVD) process is a sequence of events where gaseous precursor molecules are transported to a heated substrate, react on its surface to form a solid material, and are then removed. While this sounds simple, the process can be broken down into several distinct physical and chemical steps that must be precisely controlled to create a high-quality thin film.

The success of Chemical Vapor Deposition isn't just about following steps; it's about mastering the delicate balance between mass transport (getting reactants to the surface) and surface kinetics (how fast they react). Every stage is a control point that directly impacts the quality, thickness, and uniformity of the final thin film.

The Core Stages of Deposition

The CVD process is best understood as a continuous flow, from the gas inlet to the exhaust pump. For clarity, we can segment this flow into four primary stages that occur after the chamber and substrate have been properly prepared.

Stage 1: Introduction and Transport of Reactants

Reactant gases, known as precursors, are introduced into the reaction chamber at controlled flow rates.

These precursors do not simply flood the chamber. They must travel from the main gas flow, diffuse through a stationary "boundary layer" of gas above the substrate, and finally reach the substrate surface. This journey is the mass transport step.

Stage 2: Adsorption on the Substrate

Once a precursor molecule reaches the substrate, it must physically stick to the surface in a process called adsorption.

This is a temporary attachment, allowing the molecule to potentially move around on the surface before it reacts or detaches. The temperature of the substrate heavily influences this step.

Stage 3: Surface Reaction and Film Growth

This is the heart of the CVD process. The adsorbed precursor molecules gain energy from the heated substrate, causing them to decompose and react, forming the desired solid film material.

This surface reaction happens in two phases: nucleation, where initial islands of the film material form, followed by growth, where these islands coalesce and build up the film layer by layer.

Stage 4: Desorption and Removal of Byproducts

The chemical reactions on the surface inevitably create gaseous waste products, known as byproducts.

These byproducts must detach from the surface (desorption) and be transported away from the substrate. They are then removed from the chamber by the exhaust system to prevent them from contaminating the growing film.

Understanding the Critical Trade-offs

The quality of a CVD film is determined by a competition between how fast reactants can be supplied (mass transport) and how fast they react on the surface (kinetics). This creates two distinct operating regimes.

The Mass-Transport-Limited Regime

In this state, the surface reaction is extremely fast compared to the speed at which precursor gases can be delivered to the substrate.

The result is often rapid but non-uniform growth. Areas closer to the gas inlet receive more reactants and grow a thicker film, leading to poor consistency across the substrate.

The Reaction-Rate-Limited (Kinetics-Limited) Regime

Here, the precursor gases are supplied much faster than the surface reaction can consume them. The growth rate is solely determined by the reaction speed, which is a strong function of temperature.

This regime is highly desirable because it produces exceptionally uniform and high-quality films. As long as the temperature is consistent across the substrate, the film will grow at the same rate everywhere.

Applying This to Your Process

Understanding these steps allows you to troubleshoot issues and optimize your deposition for specific outcomes. The key is to see each stage as a control lever.

- If your primary focus is high-quality, uniform films: You must operate in the reaction-rate-limited regime by ensuring an ample supply of precursors and precisely controlling the substrate temperature.

- If your primary focus is achieving maximum deposition speed: You may push toward the mass-transport-limited regime, but you must actively manage the resulting non-uniformity through reactor design and gas flow dynamics.

- If your primary focus is film purity and density: Pay close attention to precursor purity and the efficiency of byproduct removal (Stage 4), as trapped byproducts can create defects.

By viewing the CVD process as a dynamic balance of transport and reaction, you can move from simply following a procedure to truly engineering a desired outcome.

Summary Table:

| CVD Process Stage | Key Action | Critical Control Parameter |

|---|---|---|

| 1. Introduction & Transport | Precursor gases flow to the substrate | Gas flow rate, pressure |

| 2. Adsorption | Molecules stick to the substrate surface | Substrate temperature |

| 3. Surface Reaction & Growth | Precursors decompose, forming the solid film | Temperature (kinetics) |

| 4. Desorption & Removal | Gaseous byproducts are pumped away | Exhaust efficiency, pressure |

Ready to engineer superior thin films with precise control over every CVD stage?

At KINTEK, we specialize in providing the high-quality lab equipment and consumables you need to master the delicate balance of mass transport and surface kinetics. Whether your goal is maximum uniformity, high deposition speed, or ultimate film purity, our solutions are designed to meet the exacting demands of your laboratory.

Contact us today to discuss how KINTEK can optimize your CVD process and help you achieve your specific material deposition outcomes.

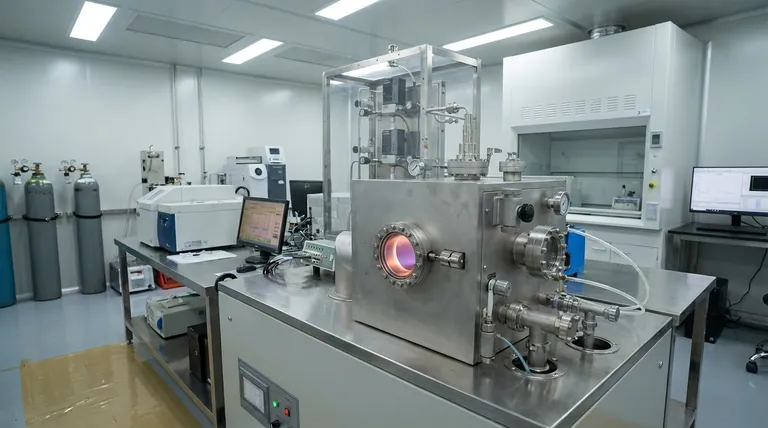

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are the units for deposition rate? Mastering Thickness and Mass Metrics for Your Process

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- How much does CVD diamond equipment cost? A Breakdown of Investment from Lab to Production

- What is the atomic layer deposition technique? Unlock Atomic-Level Precision for Your Thin Films

- What is the composition of a CVD diamond? Discover the Pure Carbon Structure of Lab-Grown Gems

- What is the process of making diamonds called? Discover HPHT & CVD Lab-Grown Methods

- How do vacuum pumps and pressure control systems affect LCVD thin film quality? Master Morphological Engineering

- What is the catalytic CVD process? Unlock Precise Control for Advanced Materials Growth