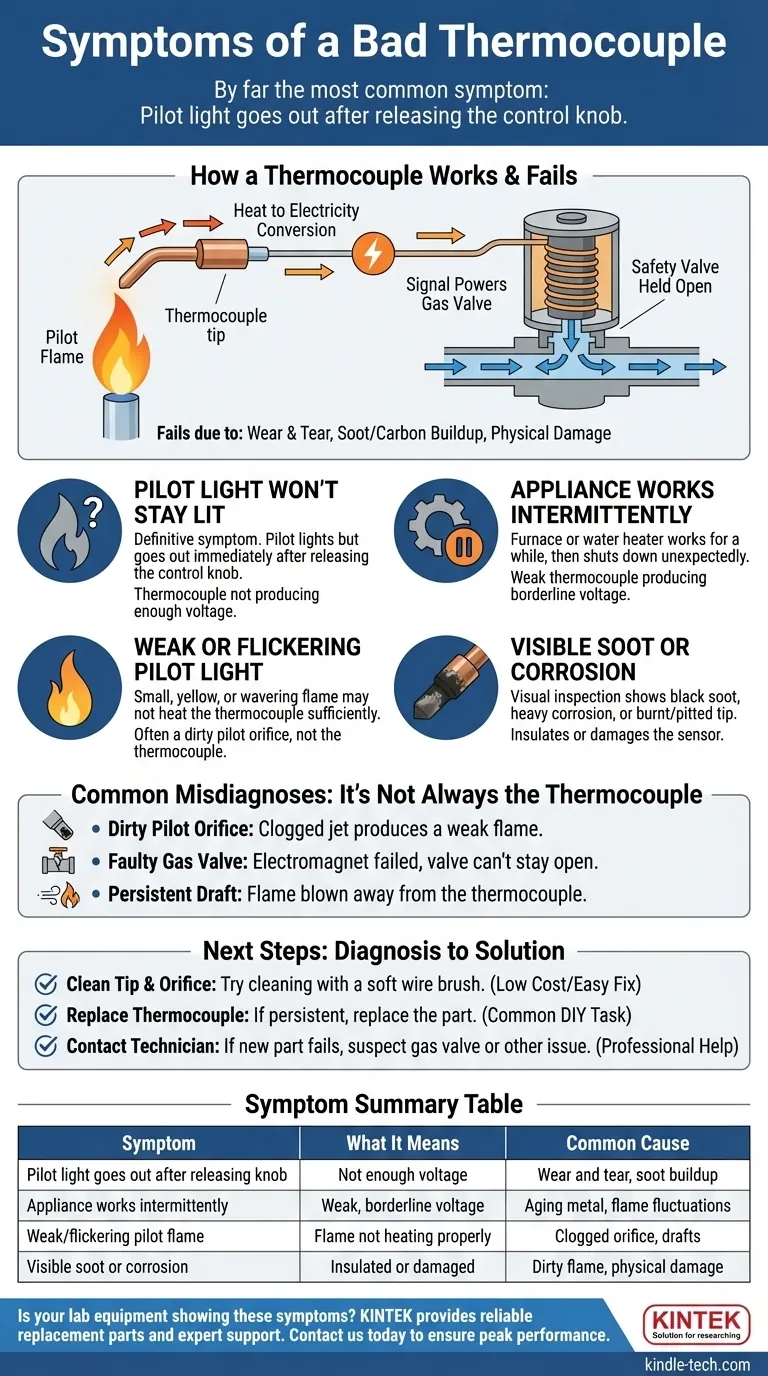

By far the most common symptom of a bad thermocouple is a pilot light that goes out as soon as you release the control knob. If you can light the pilot, but it won't stay lit on its own, a failing thermocouple is the primary suspect. This occurs because the device is no longer generating the necessary electrical signal to tell the gas valve that a flame is safely present.

A thermocouple is a simple safety device. Its failure doesn't cause a dangerous condition; it creates a safe one by shutting off the gas. Understanding its symptoms is about diagnosing an appliance that has correctly defaulted to its "off" state.

How a Thermocouple Works (And Why It Fails)

A thermocouple is a sensor that converts heat into a tiny amount of electricity. It acts as a flame-sensing safety switch in many gas appliances like furnaces, water heaters, and older gas fireplaces.

The Basic Principle

The thermocouple tip sits directly in the pilot light's flame. When heated, it generates a small millivolt signal. This electrical current travels to the gas valve, where it powers a small electromagnet that holds a safety valve open, allowing gas to flow to the pilot.

Why It Prevents Danger

If the pilot flame extinguishes for any reason, the thermocouple cools down instantly. The electrical signal stops, the electromagnet de-energizes, and the safety valve snaps shut. This stops the flow of unburnt gas, preventing a potential explosion.

Common Modes of Failure

Failure typically happens in one of three ways:

- Wear and Tear: Over thousands of heating and cooling cycles, the metal fatigues and can no longer generate a sufficient voltage.

- Soot or Carbon Buildup: A dirty pilot flame can deposit a layer of soot on the thermocouple tip. This insulates it from the flame, preventing it from getting hot enough.

- Physical Damage or Misalignment: The tip can be bent away from the hottest part of the flame, or it can crack and burn out over time.

Diagnosing the Key Symptoms

While a pilot light that won't stay lit is the classic sign, other symptoms can point to a thermocouple that is failing intermittently or is on the verge of complete failure.

Symptom: The Pilot Light Won't Stay Lit

This is the definitive symptom. You can press the gas control knob, light the pilot with a lighter, and see a steady flame. However, moments after you release the knob, the flame goes out. This indicates the thermocouple is not producing the millivoltage needed to hold the gas valve open.

Symptom: The Appliance Works Intermittently

Your furnace or water heater may work fine for hours or days, then suddenly shut down. After relighting the pilot, it works again for a random period. This suggests the thermocouple is weak and producing a borderline voltage. Minor drafts or fluctuations in gas pressure can be enough to cool it slightly and cause a shutdown.

Symptom: A Weak or Flickering Pilot Light

While often a problem with the pilot orifice itself, a weak pilot flame can also be a symptom related to the thermocouple. If the flame is small, yellow, or wavers, it may not be hot enough to properly heat the thermocouple, causing the system to shut down. The thermocouple is working, but the flame isn't doing its job.

Symptom: Visible Soot or Corrosion

A quick visual inspection can be very telling. If the thermocouple's copper tip is coated in black soot, heavily corroded, or appears burnt and pitted, it is very likely compromised. A clean, smooth tip is necessary for proper heat transfer.

Misdiagnosis: When It's Not the Thermocouple

It is crucial to understand that other components can mimic the symptoms of a bad thermocouple. Ruling these out can save you time and the cost of replacing a part that isn't broken.

A Dirty Pilot Orifice

This is the most common misdiagnosis. The pilot orifice is a tiny jet that directs the gas for the pilot flame. If it becomes clogged with dust or debris, it will produce a small, weak flame that doesn't adequately envelop the thermocouple. Cleaning the orifice and pilot assembly often solves the problem.

A Faulty Gas Valve

In less common scenarios, the thermocouple may be working perfectly, but the electromagnet inside the gas control valve has failed. Even with the correct voltage signal, the valve itself cannot stay open. This is a more complex and expensive repair.

A Persistent Draft

If the appliance is in a drafty area, the pilot flame can be blown away from the thermocouple. The thermocouple cools, thinks the flame is out, and correctly shuts off the gas. Ensuring draft shields are in place and sealing the area can resolve this.

Next Steps: From Diagnosis to Solution

Once you have analyzed the symptoms, you can take a logical next step.

- If you suspect soot or minor misalignment: First, try cleaning the thermocouple tip and the pilot orifice with a soft wire brush or steel wool. This costs nothing and is a very common fix.

- If the pilot light issue is persistent and cleaning doesn't work: Replace the thermocouple. It is a standard, inexpensive part, and replacing it is a common DIY task for those comfortable working on gas appliances.

- If a new thermocouple does not solve the problem: The issue is likely the gas control valve or another system component. At this point, it is best to contact a qualified HVAC technician for a professional diagnosis.

Following this diagnostic process empowers you to identify the problem accurately and make an informed decision on the repair.

Summary Table:

| Symptom | What It Means | Common Cause |

|---|---|---|

| Pilot light goes out after releasing knob | Thermocouple not generating enough voltage | Wear and tear, soot buildup |

| Appliance works intermittently | Thermocouple producing weak, borderline voltage | Aging metal, minor flame fluctuations |

| Weak or flickering pilot flame | Flame not heating thermocouple properly | Clogged pilot orifice, drafts |

| Visible soot or corrosion on tip | Thermocouple is insulated or damaged | Dirty flame, physical damage |

Is your lab equipment's heating system showing these symptoms? KINTEK specializes in lab equipment and consumables, providing reliable replacement parts and expert support to keep your laboratory running safely and efficiently. Don't let a faulty component disrupt your work—contact our experts today for a consultation and ensure your lab's critical systems are operating at peak performance.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

People Also Ask

- What material is used for furnace heating? Select the Right Element for Your Process

- What is the thermal expansion coefficient of molybdenum disilicide? Understanding its role in high-temperature design

- What are the properties of molybdenum heating element? Choose the Right Type for Your Furnace Atmosphere

- What is molybdenum disilicide used for? Powering High-Temperature Furnaces Up to 1800°C

- What function do molybdenum disilicide heating elements perform? Precision Heat for Pulverized Coal Research