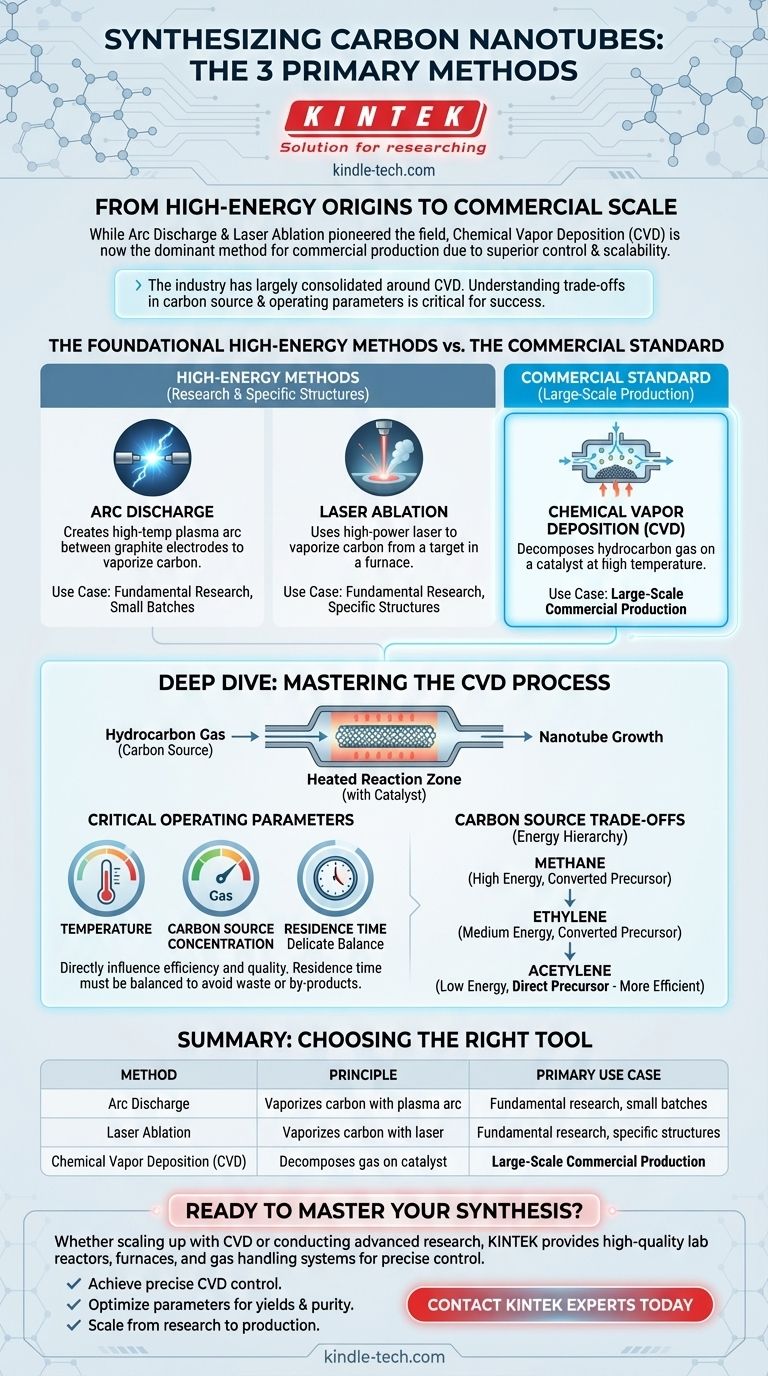

The three primary methods for synthesizing carbon nanotubes are arc discharge, laser ablation, and Chemical Vapor Deposition (CVD). While arc discharge and laser ablation were the original techniques used to produce them, CVD has since become the dominant process for commercial-scale production due to its superior control and scalability.

While multiple methods exist, the industry has largely consolidated around Chemical Vapor Deposition (CVD). Understanding the trade-offs within the CVD process—specifically the choice of carbon source and operating parameters—is now the critical factor for successful synthesis.

The Foundational High-Energy Methods

The first carbon nanotubes were created using techniques that rely on vaporizing a solid carbon source at extremely high temperatures. These methods are effective for small-scale research but are less common for industrial production.

Arc Discharge

The arc discharge method involves creating a high-temperature plasma arc between two graphite electrodes. This intense heat vaporizes the carbon from one of the electrodes, which then condenses to form nanotubes.

Laser Ablation

In laser ablation, a high-power laser is aimed at a graphite target in a high-temperature furnace. The laser vaporizes the carbon, which is then swept away by an inert gas, allowing it to cool and self-assemble into nanotubes.

The Commercial Standard: Chemical Vapor Deposition (CVD)

CVD has become the go-to method for producing carbon nanotubes in large quantities. It offers a higher degree of control over the final product's structure compared to the high-energy methods.

How CVD Works

The CVD process involves introducing a hydrocarbon gas (a carbon source) into a high-temperature chamber. When the gas comes into contact with a catalyst, the carbon atoms break away and arrange themselves into the nanotube structure.

The Critical Operating Parameters

The success of the CVD process hinges on three key variables. These parameters directly influence the efficiency of the synthesis and the quality of the nanotubes produced.

The three parameters are temperature, carbon source concentration, and residence time.

The Importance of Residence Time

Residence time—how long the carbon source remains in the reaction zone—is a delicate balance. If the time is too short, the carbon source is wasted. If it is too long, unwanted by-products can accumulate and hinder growth.

Understanding the Trade-offs in Carbon Sources

Not all carbon sources are equal. The choice of hydrocarbon gas for the CVD process has significant implications for the energy required and the efficiency of the reaction.

The Energy Hierarchy

Different gases require different amounts of energy to break down and release their carbon. The energy needed for successful synthesis follows a clear hierarchy.

Methane requires the most energy, followed by ethylene, and finally acetylene, which requires the least.

Direct vs. Converted Precursors

This energy difference is due to how the molecules act as precursors. Methane and ethylene need a thermal conversion process to form the carbon building blocks for nanotubes.

In contrast, acetylene can serve as a direct carbon precursor without needing an additional energy-intensive conversion step, making it a more efficient feedstock.

How to Apply This to Your Goal

The best synthesis method depends entirely on the intended application, balancing factors like scale, purity, and cost.

- If your primary focus is large-scale commercial production: Chemical Vapor Deposition (CVD) is the only viable choice due to its scalability and process control.

- If your primary focus is fundamental research or creating highly specific structures: Arc discharge or laser ablation may still be suitable for producing small batches of high-purity material.

- If your primary focus is sustainability and innovation: Investigating alternative feedstocks like captured carbon dioxide or methane pyrolysis represents the future of nanotube synthesis.

Ultimately, mastering the synthesis process is about choosing the right tool and precisely tuning the parameters to achieve your specific goal.

Summary Table:

| Method | Principle | Primary Use Case |

|---|---|---|

| Arc Discharge | Vaporizes carbon with a plasma arc between graphite electrodes. | Fundamental research, small batches. |

| Laser Ablation | Vaporizes carbon from a target using a high-power laser. | Fundamental research, specific structures. |

| Chemical Vapor Deposition (CVD) | Decomposes hydrocarbon gas on a catalyst at high temperature. | Large-scale commercial production. |

Ready to Master Your Carbon Nanotube Synthesis?

Whether you are scaling up production with a CVD system or conducting advanced research, the right lab equipment is critical for controlling parameters like temperature and gas flow. KINTEK specializes in high-quality lab reactors, furnaces, and gas handling systems tailored for advanced materials synthesis.

We provide the reliable tools you need to:

- Achieve precise control over CVD processes.

- Optimize critical parameters for higher yields and purity.

- Scale your synthesis from research to production.

Let's discuss how our equipment can help you achieve your specific goals. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating