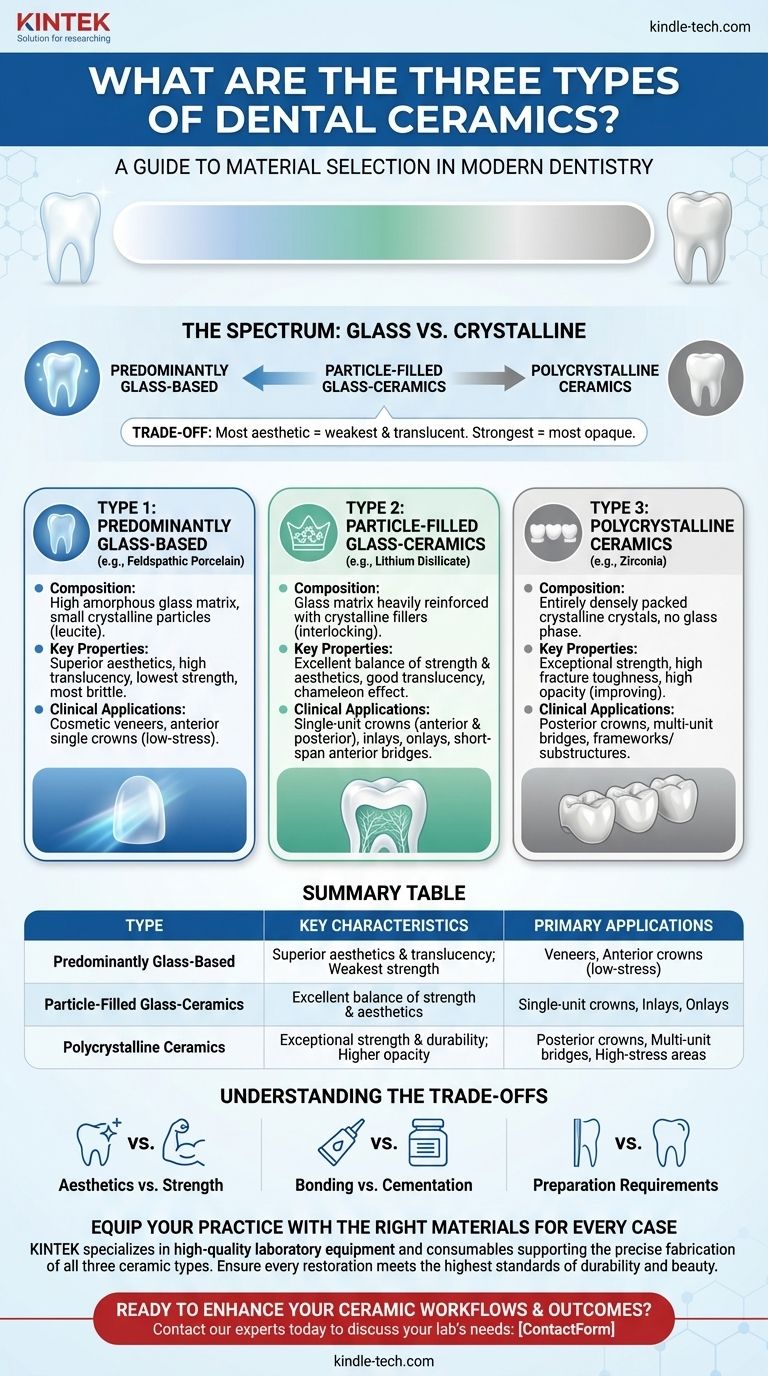

In modern dentistry, dental ceramics are broadly categorized into three main types based on their composition and microstructure. These categories are predominantly glass-based ceramics, particle-filled glass-ceramics, and polycrystalline ceramics. The primary difference between them lies in the ratio of glass (which provides translucency) to crystalline structures (which provide strength).

The selection of a dental ceramic is not about finding one "best" material, but about understanding a fundamental trade-off: The most aesthetically pleasing, glass-like materials are the weakest, while the strongest materials are the most opaque.

The Foundation of Ceramic Selection

Before comparing the types, it's crucial to understand the properties that unite all dental ceramics. This shared foundation dictates how they behave in the oral environment.

Defining Characteristics

All dental ceramics are inorganic, non-metallic materials created by firing minerals at high temperatures. As a class, they exhibit very high compressive strength, meaning they resist biting forces well.

However, they have low tensile strength and are brittle, making them susceptible to fracture when flexed or stretched. This dual nature is the central challenge in their clinical application.

The Spectrum of Strength and Aesthetics

The three types of ceramics exist on a spectrum. At one end, you have materials that are almost entirely glass, offering unmatched beauty and translucency. At the other end, you have materials that are purely crystalline, providing exceptional strength and fracture resistance.

Type 1: Predominantly Glass-Based Ceramics

Often called feldspathic or porcelain ceramics, these are the original materials used for aesthetic restorations.

Composition and Structure

These ceramics have a high concentration of an amorphous glass matrix with a small amount of crystalline particles (like leucite) mixed in. Their structure is what makes them highly translucent, closely mimicking natural tooth enamel.

Key Properties

Their main advantage is superior aesthetics. No other ceramic type can replicate the subtle translucency and optical effects of a natural tooth as effectively. Their primary disadvantage is being the weakest and most brittle of the ceramic classes.

Clinical Applications

Due to their lower strength, their use is limited to low-stress applications. They are the gold standard for cosmetic veneers and occasionally for single anterior crowns where aesthetic demands are the absolute priority.

Type 2: Particle-Filled Glass-Ceramics

This category represents a significant leap forward in material science, creating a versatile "workhorse" material for everyday dentistry. Lithium disilicate is the most prominent example.

Composition and Structure

These materials start with a glass matrix but are heavily reinforced with crystalline filler particles, such as lithium disilicate. These fillers interlock and deflect cracks, dramatically increasing the material's strength compared to traditional feldspathic porcelain.

Key Properties

Lithium disilicate offers an excellent balance of strength and aesthetics. It is significantly stronger than glass-based ceramics while still providing very good translucency and chameleon-like effects, allowing it to blend seamlessly with adjacent teeth.

Clinical Applications

This balance makes it ideal for a wide range of restorations, including single-unit crowns (anterior and posterior), inlays, onlays, and even short-span anterior bridges.

Type 3: Polycrystalline Ceramics

These materials are at the opposite end of the spectrum from glass-based ceramics, prioritizing strength above all else. Zirconia (zirconium dioxide) is the definitive material in this class.

Composition and Structure

Polycrystalline ceramics contain no glass phase. They are composed entirely of densely packed, high-strength crystals. This structure effectively stops cracks from propagating, giving the material immense fracture toughness.

Key Properties

Zirconia's defining characteristic is its exceptional strength, which is comparable to that of some metals. This allows it to be used in thin sections and in the highest-stress areas of the mouth. The trade-off is its high opacity, which historically made it less aesthetic, though modern formulations have improved translucency.

Clinical Applications

Zirconia is the material of choice for situations demanding maximum durability. This includes posterior crowns, multi-unit bridges, and as a framework or substructure for weaker, more aesthetic porcelain layered on top.

Understanding the Trade-offs

Choosing a ceramic involves more than just looking at the final restoration; it impacts the entire clinical workflow.

Aesthetics vs. Strength

This is the core decision matrix. The more glass in the ceramic, the better its translucency and aesthetic potential. The more crystalline structures, the higher its fracture resistance and strength.

Bonding vs. Cementation

The material's composition dictates how it attaches to the tooth. Glass-containing ceramics (Types 1 and 2) must be etched and adhesively bonded to the tooth structure for maximum strength and retention. High-strength polycrystalline ceramics like zirconia can often be conventionally cemented, simplifying the clinical procedure.

Preparation Requirements

Stronger materials like zirconia can sometimes be used in thinner cross-sections, potentially allowing for a more conservative tooth preparation that preserves more natural tooth structure. Weaker materials require a certain bulk for strength, which may necessitate more tooth reduction.

Matching the Material to the Clinical Goal

To make a definitive choice, align the material's properties directly with the primary objective of the restoration.

- If your primary focus is maximum aesthetics in a low-stress area: Predominantly glass-based ceramics are the superior choice for veneers.

- If your primary focus is a versatile balance of strength and beauty for single crowns: Particle-filled glass-ceramics like lithium disilicate are the industry standard.

- If your primary focus is maximum durability for posterior teeth or bridges: Polycrystalline ceramics like zirconia are the most reliable option.

Understanding this spectrum from glass to crystal empowers you to select the ideal material for any clinical scenario.

Summary Table:

| Type of Ceramic | Key Characteristics | Primary Clinical Applications |

|---|---|---|

| Predominantly Glass-Based | Superior aesthetics & translucency; weakest strength | Veneers, anterior crowns (low-stress) |

| Particle-Filled Glass-Ceramics | Excellent balance of strength & aesthetics | Single-unit crowns (anterior/posterior), inlays, onlays |

| Polycrystalline Ceramics | Exceptional strength & durability; higher opacity | Posterior crowns, multi-unit bridges, high-stress areas |

Equip your practice with the right materials for every case.

Understanding the spectrum of dental ceramics is key to clinical success. Whether your priority is unmatched aesthetics for a veneer or the supreme strength required for a multi-unit bridge, selecting the correct material is paramount.

KINTEK specializes in providing high-quality laboratory equipment and consumables that support the precise fabrication of all three ceramic types. Our products help dental labs and clinics achieve consistent, reliable results, ensuring every restoration meets the highest standards of durability and beauty.

Ready to enhance your ceramic workflows and outcomes? Contact our experts today to discuss how KINTEK can support your laboratory's specific needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs