Fundamentally, Physical Vapor Deposition (PVD) is classified into two primary methods based on the physical process used to create the vapor: Sputtering and Thermal Evaporation. While coatings are also categorized by their end-use, such as functional or decorative, these two underlying processes represent the core technical distinction in how a PVD coating is made.

While PVD coatings are often discussed by their application (e.g., functional vs. decorative), the true distinction lies in the underlying physical process used to create them. The choice between Sputtering and Thermal Evaporation directly dictates the coating's final properties, performance, and ideal use case.

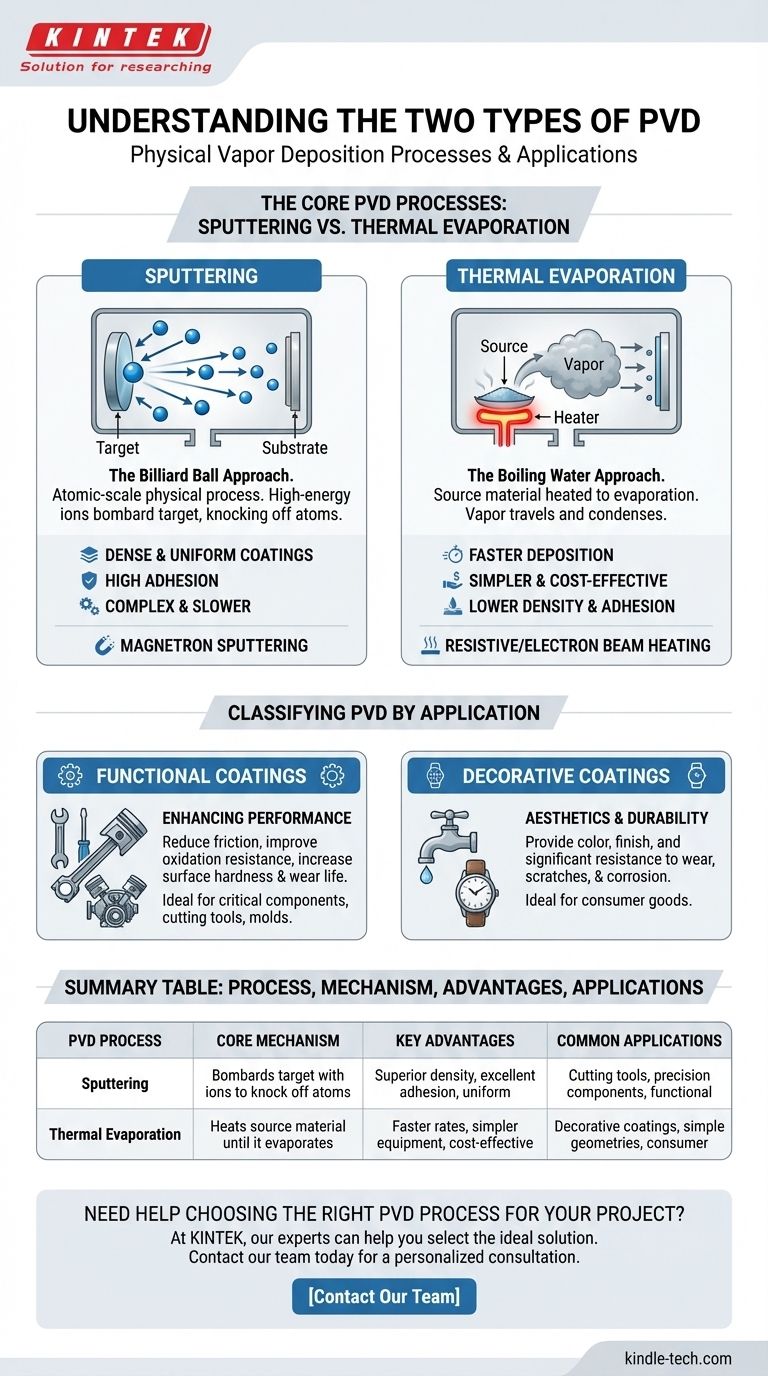

The Core PVD Processes Explained

To understand PVD, you must first understand the two main ways atoms are liberated from a solid source material to be deposited onto a substrate. These methods are fundamentally different and yield coatings with distinct characteristics.

Sputtering: The Billiard Ball Approach

Sputtering is an atomic-scale physical process. It involves bombarding a solid source material, known as the "target," with high-energy ions in a vacuum environment.

This energetic bombardment acts like a cue ball striking a rack of billiard balls. The impact has enough force to physically knock atoms off the target material, which then travel through the vacuum chamber and deposit onto the component being coated.

This method produces a very dense, uniform, and highly adherent thin film. Magnetron sputtering is a common variant that uses magnetic fields to trap electrons near the target, increasing the efficiency of the ion bombardment.

Thermal Evaporation: The Boiling Water Approach

Thermal Evaporation is a more intuitive process. The source material is heated in a high vacuum chamber until it begins to boil and evaporate, releasing a vapor of atoms.

This vapor then travels in a straight line until it condenses on the cooler surface of the substrate, forming the coating. The heating can be achieved through methods like resistive heating or by using a high-energy electron beam.

This process is generally faster than sputtering but can result in a coating that is less dense and may have weaker adhesion to the substrate.

Classifying PVD by Application

While the physical process is the technical differentiator, in practice, PVD is often discussed in terms of its final goal. This leads to the second, more application-focused classification.

Functional Coatings: Enhancing Performance

Functional PVD coatings are engineered specifically to improve the physical properties of a tool or component. The primary goal is performance, not aesthetics.

These coatings are designed to reduce friction, improve oxidation resistance, and dramatically increase surface hardness and wear resistance. This extends the life of critical components like cutting tools, molds, and engine parts.

Decorative Coatings: Combining Aesthetics and Durability

Decorative PVD coatings are used to provide a specific color, finish, and appearance to a product. However, they are far more than just a paint layer.

These coatings also provide a significant level of durability and resistance to wear, scratches, and corrosion. This makes them ideal for consumer goods like watches, faucets, and hardware where both look and longevity are critical.

Understanding the Trade-offs

The choice between sputtering and evaporation is a classic engineering trade-off between performance, speed, and complexity.

Sputtering: Density and Adhesion vs. Complexity

The key advantage of sputtering is the superior quality of the film. The coatings are exceptionally dense, uniform even on complex shapes, and exhibit very strong adhesion to the substrate.

The trade-off is that deposition rates are typically slower than evaporation. The equipment required is also more complex and expensive to operate.

Evaporation: Speed and Simplicity vs. Adhesion

Thermal evaporation's main advantage is its speed and relative simplicity. It can deposit material much more quickly than sputtering, making it cost-effective for certain applications.

The downside is that the resulting film often has lower density and weaker adhesion. It can also be challenging to achieve a uniform coating on components with complex geometries due to the line-of-sight nature of the vapor stream.

Making the Right Choice for Your Goal

Selecting the correct PVD process requires aligning the method's characteristics with your primary objective.

- If your primary focus is maximum durability and adhesion for a critical tool: Sputtering is almost always the superior choice due to its dense, strongly bonded films.

- If your primary focus is a high-speed, cost-effective coating on a simple part: Thermal evaporation offers significant advantages in throughput and lower equipment complexity.

- If your primary focus is a decorative finish on a consumer product: Either process can be used, but the choice depends on the required wear resistance versus the cost and complexity you are willing to accept.

Understanding the distinction between the physical process and the final application is the key to selecting the ideal PVD solution.

Summary Table:

| PVD Process | Core Mechanism | Key Advantages | Common Applications |

|---|---|---|---|

| Sputtering | Bombards target with ions to knock off atoms | Superior film density, excellent adhesion, uniform coating on complex shapes | Cutting tools, precision components, functional coatings |

| Thermal Evaporation | Heats source material until it evaporates | Faster deposition rates, simpler equipment, cost-effective for high throughput | Decorative coatings, simple geometries, consumer goods |

Need help choosing the right PVD process for your project?

At KINTEK, we specialize in lab equipment and consumables for advanced coating applications. Whether you require the superior durability of sputtering or the high-speed efficiency of thermal evaporation, our experts can help you select the ideal solution to enhance your product's performance, durability, and aesthetics.

Contact our team today for a personalized consultation and discover how KINTEK can support your laboratory's PVD coating needs.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is vacuum thermal evaporation? A Guide to High-Purity Thin Film Deposition

- What is the process of thermal evaporation in PVD? A Step-by-Step Guide to Thin Film Deposition

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is thermal evaporation technique thin film deposition? A Guide to Simple, Cost-Effective PVD

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications