In the world of advanced engineering, "thin films" are not a monolithic category. They are most usefully classified not by what they are, but by how they are made. The two fundamental approaches are Thin Film Chemical Deposition, where films are built from reactive gases, and Thin Film Physical Vapor Deposition, where they are constructed from a vaporized solid source.

The "type" of a thin film is defined by the interplay between its final material composition and the deposition process used to create it. Understanding the core difference between Physical and Chemical deposition is the key to understanding the properties and applications of the film itself.

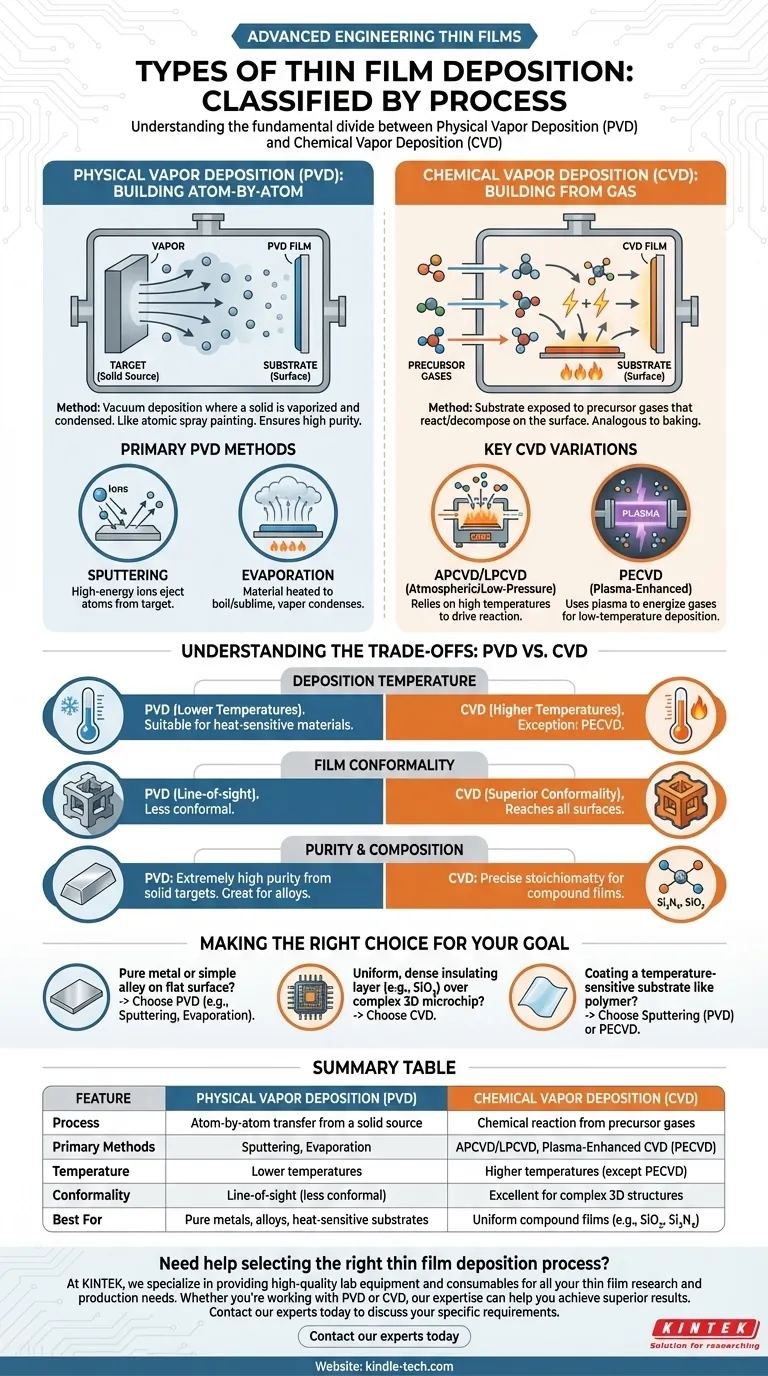

The Fundamental Divide: Physical vs. Chemical

The most critical distinction in thin film technology is the method of deposition. This choice dictates the film's structure, purity, and suitability for a given application. Every thin film is a product of one of these two foundational process families.

Physical Vapor Deposition (PVD): Building Atom-by-Atom

PVD encompasses a set of vacuum deposition methods where a solid material is converted into a vapor, transported across a vacuum chamber, and condensed onto a substrate's surface to form a solid film.

Think of PVD as a form of atomic spray painting. A solid "target" material is used as the source, ensuring high purity in the final film.

There are two primary PVD methods:

- Sputtering: In this process, the target is bombarded with high-energy ions (usually an inert gas like Argon). This atomic-scale collision ejects atoms from the target, which then travel and deposit onto the substrate.

- Evaporation: This method involves heating a material in a high vacuum until it begins to boil or sublime. The resulting vapor travels in a straight line and condenses on any cooler surface in its path, including the substrate.

Chemical Vapor Deposition (CVD): Building from Gas

CVD is a process where a substrate is exposed to one or more volatile precursor gases, which react and/or decompose on the substrate surface to produce the desired solid film.

This is analogous to baking, where different ingredients (gases) react in the presence of energy (heat) to form a new, solid structure (the film).

Key CVD variations include:

- Atmospheric/Low-Pressure CVD (APCVD/LPCVD): These classic methods rely primarily on high temperatures to drive the chemical reaction on the substrate surface.

- Plasma-Enhanced CVD (PECVD): This process uses a plasma to energize the precursor gases, allowing the deposition to occur at much lower temperatures. This is critical for coating materials that cannot withstand intense heat.

Understanding the Trade-offs: PVD vs. CVD

Choosing between PVD and CVD involves a series of engineering trade-offs tied directly to the desired outcome.

Deposition Temperature

CVD processes are generally performed at high temperatures to facilitate the chemical reactions. The major exception is PECVD, which is a low-temperature process.

PVD processes are typically performed at lower temperatures, making them suitable for coating heat-sensitive materials like plastics.

Film Conformality

Conformality describes how well a film coats over complex, non-flat surface features.

CVD processes are generally superior for conformality. Because the precursor gases can reach all parts of a surface, they create highly uniform films, even inside deep trenches or holes.

PVD is a "line-of-sight" process. Areas that are shadowed from the source material will receive little or no coating, making it less ideal for complex 3D structures.

Film Purity and Composition

PVD can produce extremely high-purity films, as the process starts with a high-purity solid target. Sputtering is also exceptionally good at depositing complex alloys and compounds by using a target of the same composition.

CVD excels at creating compound films where precise stoichiometry is critical, such as silicon nitride (Si₃N₄) or silicon dioxide (SiO₂), as the film is built through a controlled chemical reaction.

Making the Right Choice for Your Goal

The best deposition method is entirely dependent on the film material you need and the substrate you are coating.

- If your primary focus is a pure metal or simple alloy on a relatively flat surface: PVD methods like sputtering or evaporation are often the most direct and effective choice.

- If your primary focus is a uniform, dense insulating layer (like SiO₂) over a complex 3D microchip: A CVD process is almost always required for its superior conformality.

- If your primary focus is coating a temperature-sensitive substrate like a polymer: Look to lower-temperature processes like sputtering (PVD) or Plasma-Enhanced CVD (PECVD).

By starting with your material and application needs, you can navigate the landscape of deposition techniques to engineer the exact thin film required.

Summary Table:

| Feature | Physical Vapor Deposition (PVD) | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Process | Atom-by-atom transfer from a solid source | Chemical reaction from precursor gases |

| Primary Methods | Sputtering, Evaporation | APCVD/LPCVD, Plasma-Enhanced CVD (PECVD) |

| Temperature | Lower temperatures | Higher temperatures (except PECVD) |

| Conformality | Line-of-sight (less conformal) | Excellent for complex 3D structures |

| Best For | Pure metals, alloys, heat-sensitive substrates | Uniform compound films (e.g., SiO₂, Si₃N₄) |

Need help selecting the right thin film deposition process for your application?

At KINTEK, we specialize in providing high-quality lab equipment and consumables for all your thin film research and production needs. Whether you're working with PVD for pure metals or CVD for complex coatings, our expertise can help you achieve superior results.

Contact our experts today to discuss your specific requirements and discover how KINTEK solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application