The primary use of tyre oil is as a low-cost industrial fuel. Derived from the pyrolysis of end-of-life tires, this oil serves as a direct, heavy-duty substitute for conventional furnace oil, petroleum coke, or light diesel oil in applications that require significant heat generation, such as industrial boilers, furnaces, and kilns.

Tyre oil, also known as Tyre Pyrolysis Oil (TPO), is fundamentally a raw, unrefined energy source. Its immediate value lies in its high heating capacity as an industrial fuel, but unlocking its potential as a higher-grade product like diesel requires significant processing and refinement to overcome its inherent impurities.

The Nature of Tyre Pyrolysis Oil (TPO)

What Is Pyrolysis Oil?

Tyre pyrolysis is a process of heating whole or shredded tires in a reactor without oxygen. This thermal decomposition breaks the rubber down into its core components: pyrolysis oil, carbon black, steel wire, and syngas.

The resulting oil is a complex, viscous liquid mixture of hydrocarbons. Think of it as a synthetic crude oil, with its own unique properties and challenges.

Key Characteristics

The utility of TPO is defined by its physical and chemical properties. It generally has a high calorific (heating) value, often comparable to diesel, making it an excellent source of energy.

However, it is also characterized by high viscosity, a significant sediment content, and most critically, a high sulfur content. These properties dictate how and where it can be used effectively.

Primary Applications: From Raw Fuel to Refined Product

Direct Use as an Industrial Fuel

The most common and straightforward application for raw TPO is as a heating fuel. It directly competes with and replaces more expensive fossil fuels in heavy industry.

This includes powering furnaces in steel and iron factories, kilns in cement plants, boilers in processing industries, and heaters for asphalt plants. Its high heating value makes it economically attractive for these high-consumption operations.

Power Generation

TPO can be used in certain types of stationary generators for electricity production. However, using it in standard diesel engines is not recommended without pre-treatment.

The oil's viscosity and impurities can clog fuel injectors and damage engine components over time. Blending it with lighter fuels or using modified engines designed for heavy fuel oil is often necessary.

Upgrading Through Distillation

To increase its value, TPO can be processed through a distillation plant, much like crude oil is refined. This process separates the oil into different fractions based on their boiling points.

The result is typically a light oil (similar to gasoline), a medium oil (often marketed as "pyrolysis diesel"), and a heavy residual oil. The heavy oil can still be used as a furnace fuel, while the lighter fractions have more specialized uses.

Understanding the Trade-offs and Challenges

The High Sulfur Problem

The most significant barrier to wider TPO use is its high sulfur content, inherited from the tire manufacturing process. Burning high-sulfur fuel releases sulfur oxides (SOx), a major pollutant and a key contributor to acid rain.

Most environmental regulations strictly limit SOx emissions, meaning the oil must either be used by facilities equipped with flue-gas desulfurization (scrubber) technology or undergo a separate, costly desulfurization process before use.

Operational Difficulties

The high viscosity and presence of fine carbon particles and other sediments mean that raw TPO is not a simple "drop-in" fuel. It requires specialized storage tanks with heating coils to keep it fluid, as well as robust, multi-stage filtration systems to prevent blockages in fuel lines and nozzles.

The "Pyrolysis Diesel" Caveat

The diesel-like fraction obtained from distillation is not equivalent to standard automotive diesel. It often fails to meet critical specifications for on-road vehicles, such as cetane number, lubricity, and long-term stability.

Using this unrefined "pyrolysis diesel" in modern engines can lead to poor performance, increased emissions, and engine damage. Its use is generally limited to less sensitive applications like agricultural machinery, off-road equipment, or stationary engines where standards are less stringent.

Making the Right Choice for Your Application

- If your primary focus is low-cost industrial heat: Use raw or filtered TPO as a direct substitute for furnace oil, but ensure your facility can handle its high viscosity and sulfur content.

- If your primary focus is producing a higher-value fuel: Invest in a distillation plant to separate TPO into different fractions, but be aware that further purification like hydrodesulfurization is needed to create a truly clean fuel.

- If your primary focus is creating a transportation fuel: Proceed with extreme caution, as extensive and expensive refining is required to produce a diesel fuel that meets legal and technical standards for on-road vehicles.

Ultimately, understanding tyre oil's role as a potent but unrefined energy source is the key to leveraging its economic and environmental benefits correctly.

Summary Table:

| Application | Key Consideration | Primary Use Case |

|---|---|---|

| Direct Industrial Fuel | High sulfur content requires emission controls | Heating furnaces, cement kilns, asphalt plants |

| Power Generation | Needs pre-treatment or engine modifications | Stationary generators, off-grid power |

| Distilled Fractions | Requires further refining for transport use | Light oil (gasoline-like), medium oil (diesel-like) |

Unlock the potential of tyre pyrolysis oil for your industrial operations with KINTEK.

As a leading supplier of lab equipment and consumables, KINTEK provides the analytical tools and processing solutions needed to safely and efficiently utilize tyre oil. Whether you're testing fuel quality, optimizing pyrolysis processes, or handling by-products like carbon black, our equipment ensures accuracy and reliability.

Let KINTEK help you:

- Analyze oil properties (viscosity, sulfur content, calorific value)

- Scale your pyrolysis operations with precision instruments

- Meet environmental standards with reliable testing gear

Contact us today to discuss how our lab solutions can support your tyre oil projects and enhance your laboratory's capabilities.

Related Products

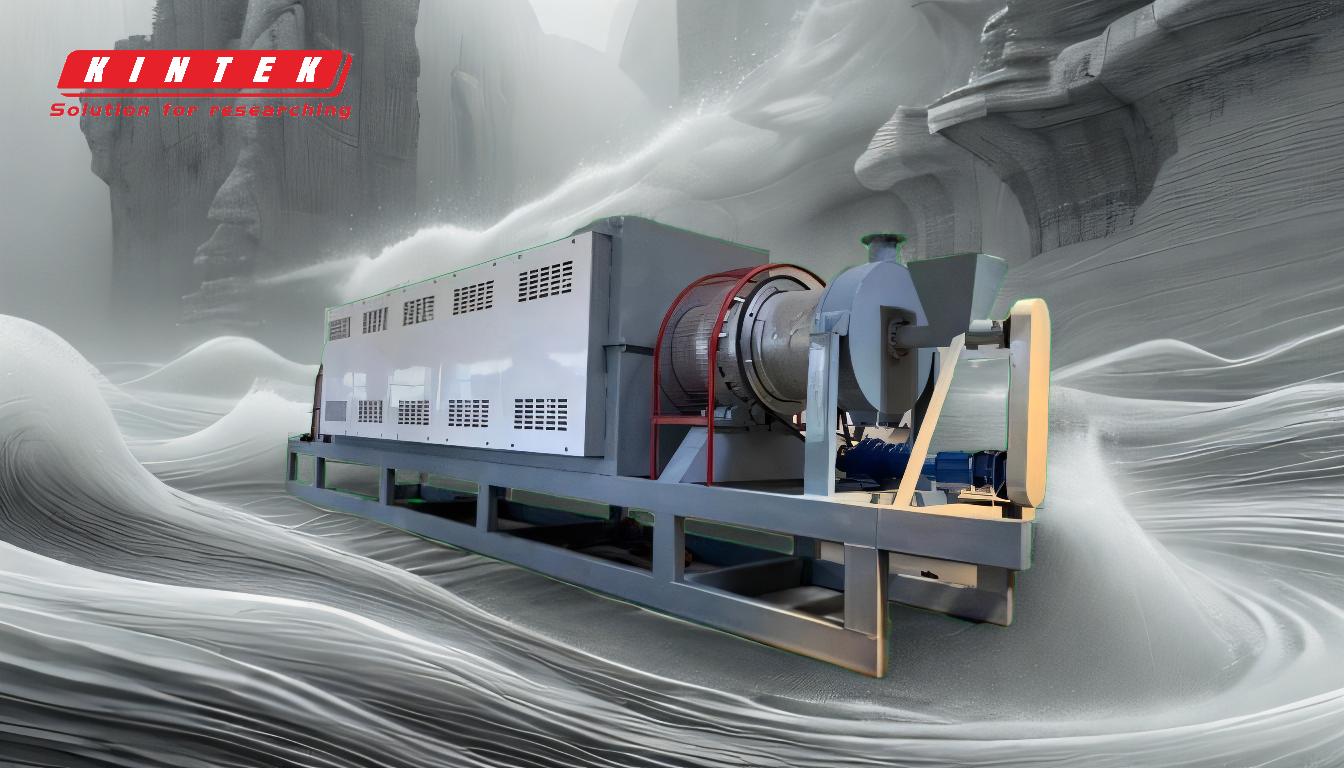

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Hydrogen Fuel Cell Stack Battery Lab Equipment

People Also Ask

- What are the outputs of tyre pyrolysis? Turn Waste Tires into Valuable Resources

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- How does a rotary kiln rotate? Discover the Core Mechanics That Drive Thermal Processing

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- How do you convert biomass into energy? A Guide to Thermochemical and Biochemical Methods