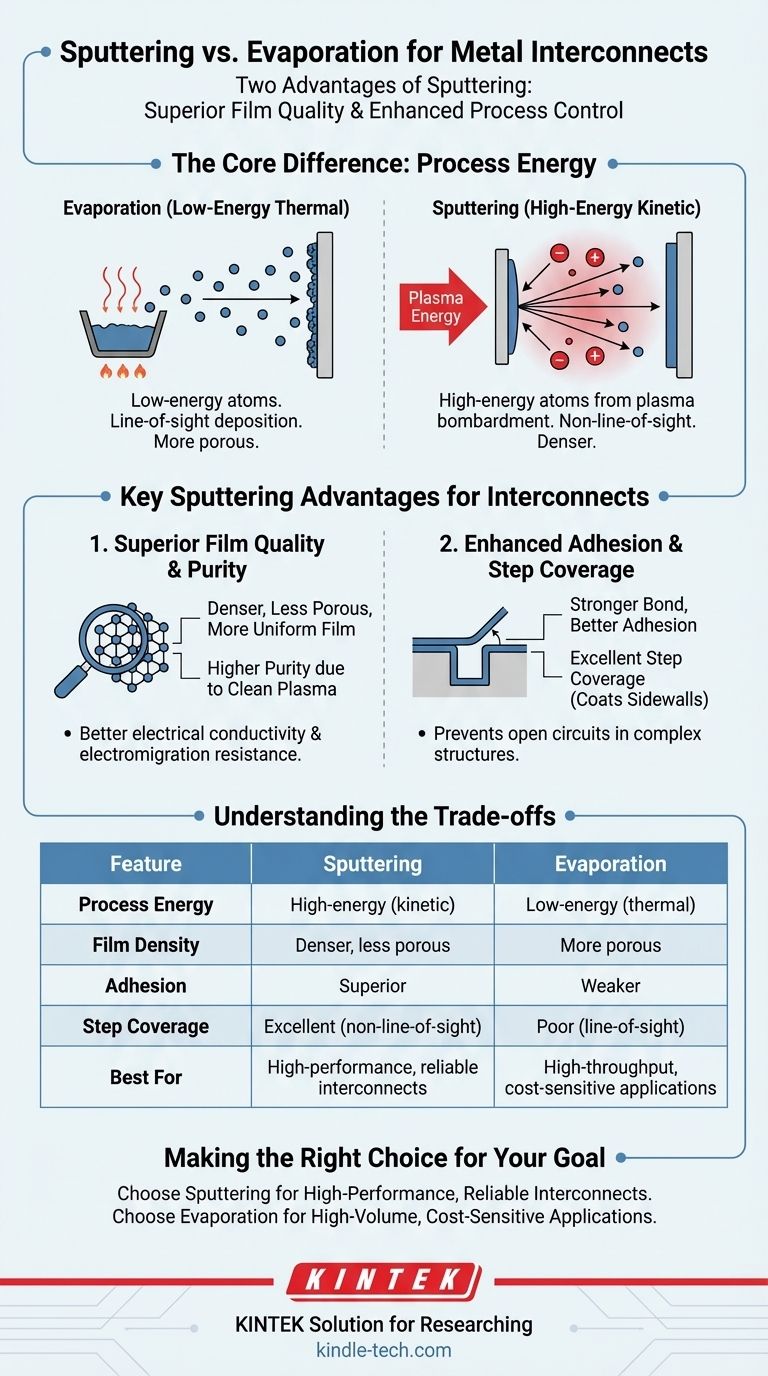

Two primary advantages of sputtering over evaporation for creating metal interconnect systems are superior film quality and enhanced process control. Sputtering utilizes a high-energy plasma environment to produce denser, purer, and more uniform films with better adhesion, which is critical for the reliability of modern integrated circuits.

The core difference lies in the energy of the deposition process. Evaporation is a low-energy thermal process driven by heat, while sputtering is a high-energy kinetic process driven by plasma bombardment, granting it superior control over the final film's properties.

The Physical Process: Why Energy Matters

To understand the advantages, we must first look at the fundamental difference between how these two methods deposit atoms onto a substrate.

Evaporation: A Line-of-Sight Thermal Method

Evaporation involves heating a source material in a vacuum chamber until it vaporizes. The gaseous atoms then travel in a straight line and condense on the cooler substrate, forming a thin film.

This process is relatively simple and fast, but the low energy of the evaporated atoms can result in a more porous film with weaker adhesion.

Sputtering: A High-Energy Kinetic Method

Sputtering takes place in a plasma environment. High-energy ions are accelerated to strike a "target" made of the desired material.

This bombardment ejects, or "sputters," atoms from the target with significant kinetic energy. These high-energy atoms then deposit onto the substrate, creating a fundamentally different type of film.

Key Sputtering Advantages for Interconnects

The high-energy nature of the sputtering process directly translates into tangible benefits for creating robust and reliable metal interconnects.

Advantage 1: Superior Film Quality and Purity

Sputtered atoms arrive at the substrate with much higher energy than evaporated atoms. This energy allows them to move around on the surface momentarily, finding optimal positions in the film's crystal lattice.

The result is a denser, less porous, and more uniform film. This density is critical for interconnects, as it leads to better electrical conductivity and resistance to electromigration, a common failure mechanism. The plasma environment also provides a cleaner deposition, leading to higher purity.

Advantage 2: Enhanced Adhesion and Step Coverage

Adhesion is paramount for interconnects, which must reliably stick to the underlying dielectric layers. The high kinetic energy of sputtered atoms effectively embeds them into the substrate surface, creating a much stronger bond than the simple condensation of evaporation.

Furthermore, sputtering provides better step coverage. Because atoms are ejected from the target in various directions, they can coat the sides and bottoms of trenches and vias more effectively than the line-of-sight deposition from evaporation, preventing open circuits.

Understanding the Trade-offs

Choosing a deposition method always involves balancing competing factors. While sputtering offers superior quality, it is not always the optimal choice.

Cost and Complexity

Sputtering systems are generally more complex and expensive to purchase and maintain. They require sophisticated power supplies for the plasma, high-quality vacuum systems, and argon gas handling. Evaporation systems are comparatively simpler and more cost-effective.

Deposition Rate

For many materials, thermal evaporation offers a significantly higher deposition rate than sputtering. This makes it more suitable for applications where high throughput and low cost are more important than the absolute highest film quality.

Material and Substrate Compatibility

The high-energy plasma in sputtering can sometimes cause damage to sensitive substrates. In contrast, the lower-energy nature of evaporation is gentler, making it a better choice for certain organic or delicate materials.

Making the Right Choice for Your Goal

Your application's specific requirements for performance, cost, and throughput will determine the best method.

- If your primary focus is high-performance, reliable interconnects: Sputtering is the superior choice for its ability to produce dense, pure films with excellent adhesion and step coverage.

- If your primary focus is high-volume production for less critical applications: Evaporation offers a compelling advantage in speed and cost-effectiveness.

Ultimately, the decision hinges on whether your priority is the uncompromising film quality of sputtering or the economic efficiency of evaporation.

Summary Table:

| Feature | Sputtering | Evaporation |

|---|---|---|

| Process Energy | High-energy (kinetic) | Low-energy (thermal) |

| Film Density | Denser, less porous | More porous |

| Adhesion | Superior | Weaker |

| Step Coverage | Excellent (non-line-of-sight) | Poor (line-of-sight) |

| Best For | High-performance, reliable interconnects | High-throughput, cost-sensitive applications |

Need to deposit high-quality metal films for your interconnects? KINTEK specializes in advanced lab equipment, including sputtering and evaporation systems, to help you achieve the precise film properties your research or production demands. Our experts can help you select the right deposition technology for superior adhesion, density, and reliability. Contact our team today to discuss your specific application and find the optimal solution!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How is the thickness of a deposited thin film measured during evaporation? Master Deposition Rate Control

- How is the thickness of a deposited film measured? Master Optical Interference Techniques

- Why is vacuum needed in thermal evaporation? For Pure, Uniform Thin Films

- What is e beam evaporation synthesis of nano films? A Guide to High-Purity Thin Films

- What metal can evaporate? A Guide to Vapor Pressure and Thin Film Deposition

- What is the vacuum evaporation technique? A Guide to Thin Film Deposition & PVD

- How does electron beam evaporation work? A Guide to High-Purity Thin-Film Deposition

- What properties are involved in evaporation? Master the Key Factors for Efficient Drying