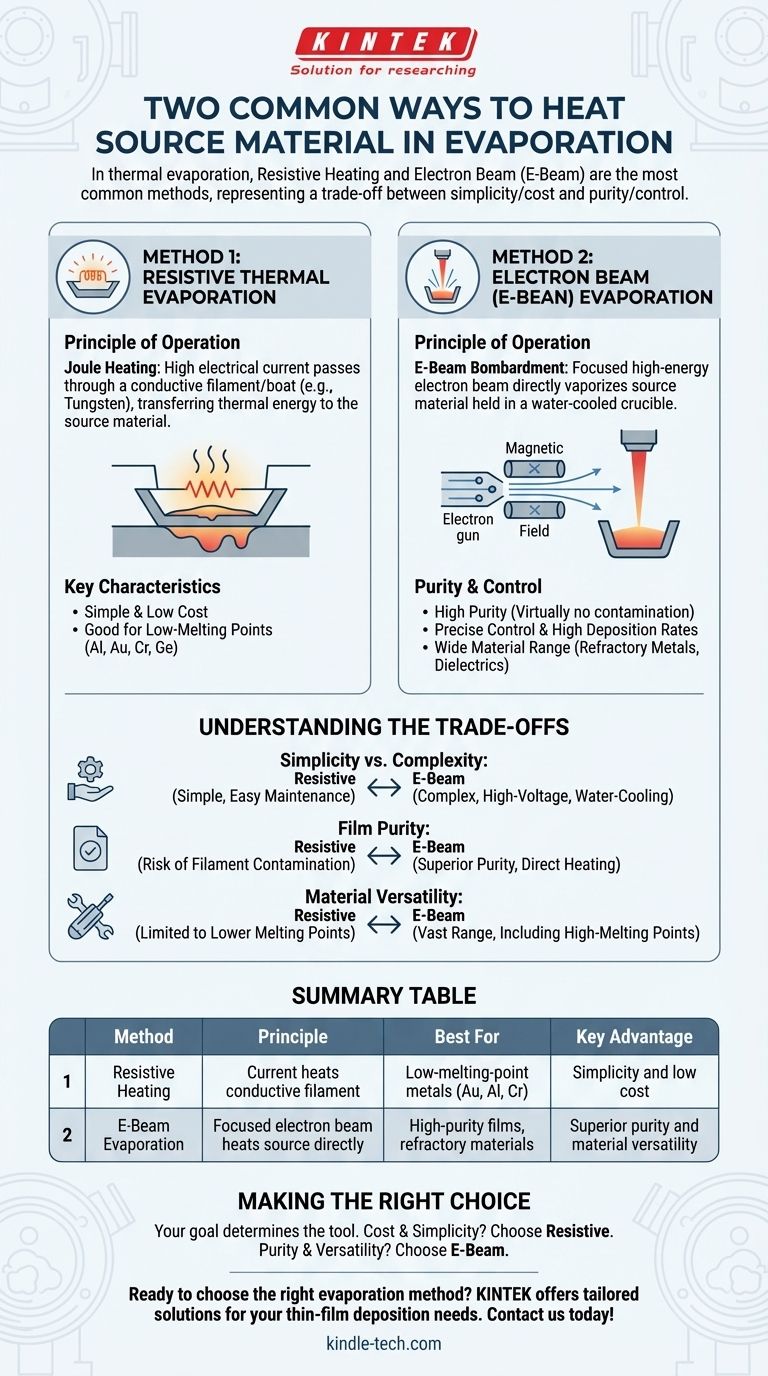

In thermal evaporation processes, the two most common methods for heating the source material are Resistive Heating and Electron Beam (E-Beam) Evaporation. Resistive heating functions much like a simple filament in a lightbulb, passing an electrical current through a material to generate heat. E-Beam evaporation, by contrast, uses a focused beam of high-energy electrons to bombard and vaporize the source material directly.

The choice between these heating methods is a foundational decision in thin-film deposition. It represents a direct trade-off between the simplicity and low cost of resistive heating versus the higher purity, control, and material versatility offered by E-Beam evaporation.

Method 1: Resistive Thermal Evaporation

Resistive heating is the most straightforward method for turning a solid source material into a vapor within a vacuum chamber.

The Principle of Operation

This technique relies on Joule heating. A high electrical current is passed through a conductive, high-resistance element, often referred to as a "boat" or "filament," typically made of a refractory metal like tungsten.

The source material to be deposited (e.g., gold, chromium) is placed in direct contact with this heating element. As the element heats up, it transfers thermal energy to the source, causing it to melt and eventually evaporate into the gas phase.

Key Characteristics

The primary advantages of resistive evaporation are its simplicity and low cost. The power supplies and hardware are relatively simple, making it an accessible method for many research and small-scale production environments.

It is highly effective for materials with relatively low melting and evaporation points, such as aluminum (Al), gold (Au), chromium (Cr), and germanium (Ge).

Method 2: Electron Beam (E-Beam) Evaporation

E-Beam evaporation is a more complex and powerful technique capable of handling a much wider range of materials.

The Principle of Operation

In an E-Beam system, a filament emits electrons that are then accelerated by a high voltage potential, forming a beam. Magnetic fields are used to precisely steer and focus this high-energy electron beam onto the source material, which is held in a water-cooled crucible.

The intense kinetic energy of the electrons is transferred to the source material upon impact, causing extremely localized and rapid heating at the surface, which leads to evaporation.

Purity and Control

Because the source material is held in a cooled crucible and only the very top surface is heated by the electron beam, contamination from the container is virtually eliminated. This results in higher purity films.

This method also allows for very high deposition rates and precise control, making it a superior choice for more demanding applications.

Understanding the Trade-offs

Choosing the correct method requires a clear understanding of your project's priorities regarding cost, purity, and material type.

Simplicity vs. Complexity

Resistive heating is mechanically and electrically simple, making it easy to set up, operate, and maintain.

E-Beam evaporation is a far more complex system. It requires high-voltage power supplies, sophisticated magnetic steering coils, and water-cooling infrastructure, which increases both initial cost and operational complexity.

Film Purity

E-Beam evaporation is the clear winner for purity. By only heating the source material itself, it avoids introducing impurities from a boat or filament.

With resistive heating, there is always a risk that the boat material itself will evaporate slightly along with the source, potentially contaminating the final thin film.

Material Versatility

Resistive heating is limited to evaporating materials that have a lower melting point than the heating filament itself.

E-Beam evaporation can deposit a vast range of materials, including refractory metals and dielectrics with extremely high melting points, because the heat is delivered directly and efficiently.

Making the Right Choice for Your Application

Your specific goal will determine which evaporation method is the correct tool for the job.

- If your primary focus is cost-effectiveness and simplicity: Resistive thermal evaporation is the ideal choice, especially for depositing common metals with lower melting points like gold or chromium.

- If your primary focus is film purity and material versatility: Electron Beam (E-Beam) evaporation is the superior method, necessary for high-melting-point materials and applications demanding minimal contamination.

Understanding this fundamental difference in heating mechanisms empowers you to select the precise tool needed to achieve your deposition goals.

Summary Table:

| Method | Principle | Best For | Key Advantage |

|---|---|---|---|

| Resistive Heating | Electrical current heats a conductive filament/boat | Low-melting-point metals (Au, Al, Cr) | Simplicity and low cost |

| E-Beam Evaporation | Focused electron beam heats source material directly | High-purity films, refractory materials | Superior purity and material versatility |

Ready to choose the right evaporation method for your lab? KINTEK specializes in lab equipment and consumables, offering tailored solutions for your thin-film deposition needs. Whether you require the simplicity of resistive heating or the high purity of E-Beam evaporation, our experts can help you select the ideal system to enhance your research and production efficiency. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is vacuum thermal evaporation? A Guide to High-Purity Thin Film Deposition