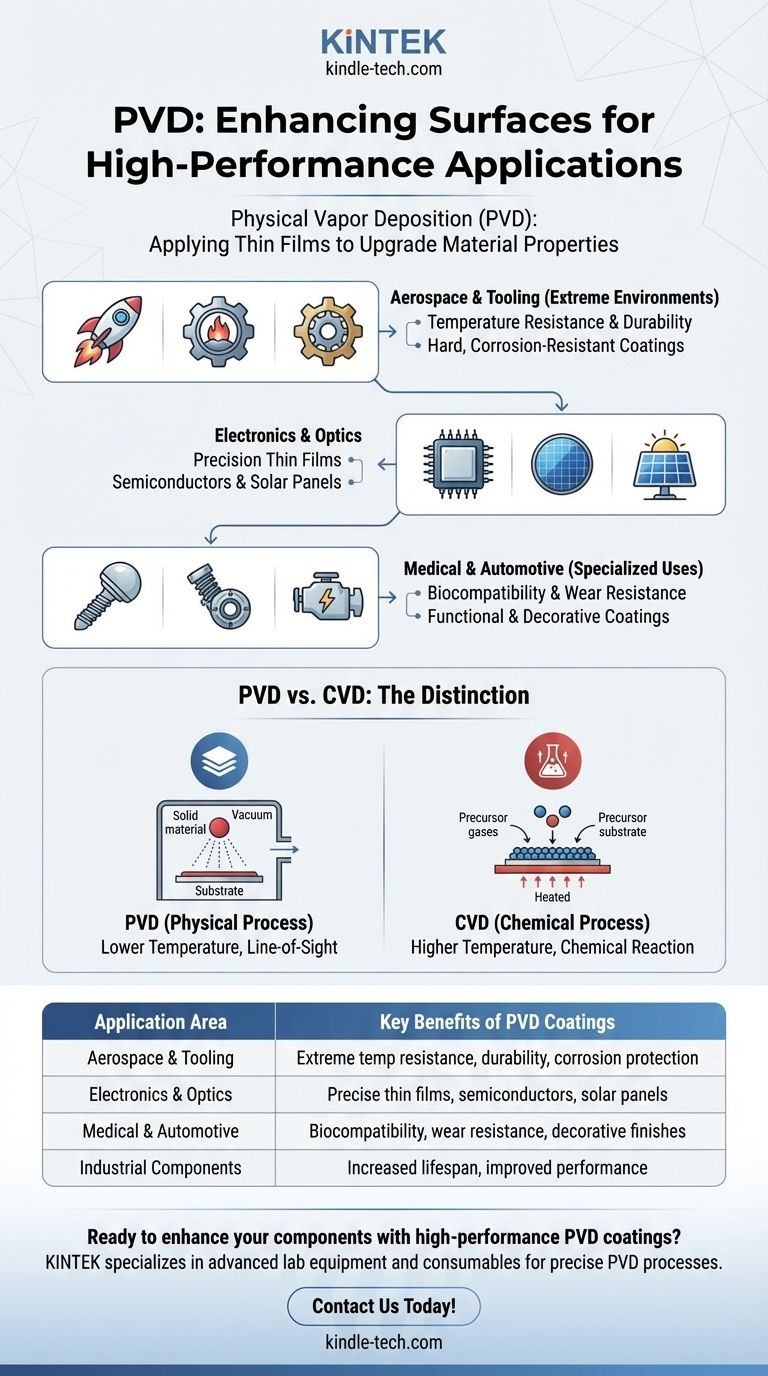

In essence, Physical Vapor Deposition (PVD) is a technique used to apply high-performance thin film coatings to a wide variety of objects. These coatings are used to enhance durability, resist extreme temperatures, or create specific optical and electronic properties. Its applications range from coating aerospace components and industrial tools to manufacturing advanced semiconductors and solar panels.

Physical Vapor Deposition is not about changing the core material, but about fundamentally upgrading its surface. It's a versatile process for adding specific, high-performance characteristics—like hardness, temperature resistance, or electrical conductivity—to an underlying substrate.

The Core Principle of PVD: Enhancing Surface Properties

Physical Vapor Deposition is a vacuum coating process where a solid material is vaporized into a plasma of atoms or molecules. This vapor is then transported and deposited as a thin, high-performance film onto a substrate, fundamentally altering its surface characteristics.

For Extreme Environments: Aerospace and Tooling

PVD is a critical process for components that must survive harsh conditions. It provides a protective layer that the base material could not achieve on its own.

Aerospace companies use PVD to apply dense, temperature-resistant coatings to engine parts and other components. This enhances their durability and ability to withstand the extreme temperatures of flight.

In industrial settings, PVD is used to apply hard, corrosion-resistant coatings to cutting tools, dies, and molds. This dramatically increases their lifespan and performance, especially in demanding environments.

For Advanced Electronics and Optics

The precision of PVD makes it indispensable for creating the microscopic layers required in modern technology. The process allows for the deposition of specific materials with unique properties.

PVD is used to apply optical films for solar panels and to deposit thin films on semiconductors. These layers control how light and electricity behave, forming the foundation of microelectronics.

Other applications include manufacturing holographic displays and creating the conductive pathways essential for electronic packaging.

For Specialized Medical and Automotive Uses

The versatility of PVD extends to highly regulated and specialized fields. The coatings can be tailored to be inert, biocompatible, or decorative.

In medicine, PVD is used to coat medical devices and implants, improving their biocompatibility and wear resistance.

Automotive parts are often coated using PVD for both functional reasons, like reducing friction, and for decorative finishes that are far more durable than traditional plating.

PVD vs. CVD: Understanding the Distinction

While PVD is a physical process (vaporizing and depositing a solid), it's important to distinguish it from its chemical counterpart, Chemical Vapor Deposition (CVD), which is also mentioned for similar applications.

The PVD Process

PVD is a "line-of-sight" process that physically transfers a material from a source to a substrate. It generally operates at lower temperatures than CVD.

The CVD Process

In contrast, Chemical Vapor Deposition (CVD) uses precursor gases that react and decompose on the substrate's surface to create the desired film.

CVD is frequently used to grow materials like carbon nanotubes and to deposit a wide range of metallic, ceramic, and semiconducting films. It is a key process for creating thin-film solar cells and protective coatings on cutting tools.

Making the Right Choice for Your Goal

Selecting the right surface enhancement technology depends entirely on the desired outcome and the properties of the substrate material.

- If your primary focus is high durability and heat resistance: PVD is an excellent choice for applying hard, temperature-resistant coatings to components like aerospace parts and industrial tools.

- If your primary focus is precise optical or electronic properties: PVD provides the control needed to deposit the thin, specific films required for semiconductors, solar panels, and advanced displays.

- If your primary focus is on growing complex materials from gaseous precursors: CVD is often the more suitable process for applications like creating carbon nanotubes or certain types of semiconductor films.

Ultimately, PVD is a cornerstone technology for enhancing materials, enabling them to perform in ways their base composition never could.

Summary Table:

| Application Area | Key Benefits of PVD Coatings |

|---|---|

| Aerospace & Tooling | Extreme temperature resistance, enhanced durability, corrosion protection |

| Electronics & Optics | Precise thin films for semiconductors, solar panels, and displays |

| Medical & Automotive | Biocompatibility, wear resistance, durable decorative finishes |

| Industrial Components | Increased tool lifespan, improved performance in harsh environments |

Ready to enhance your components with high-performance PVD coatings?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise PVD processes. Whether you're in aerospace, electronics, or medical manufacturing, our solutions help you achieve superior surface properties like hardness, temperature resistance, and specific optical or electronic characteristics.

Contact us today to discuss how KINTEK can support your laboratory's coating needs and drive innovation in your projects!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition