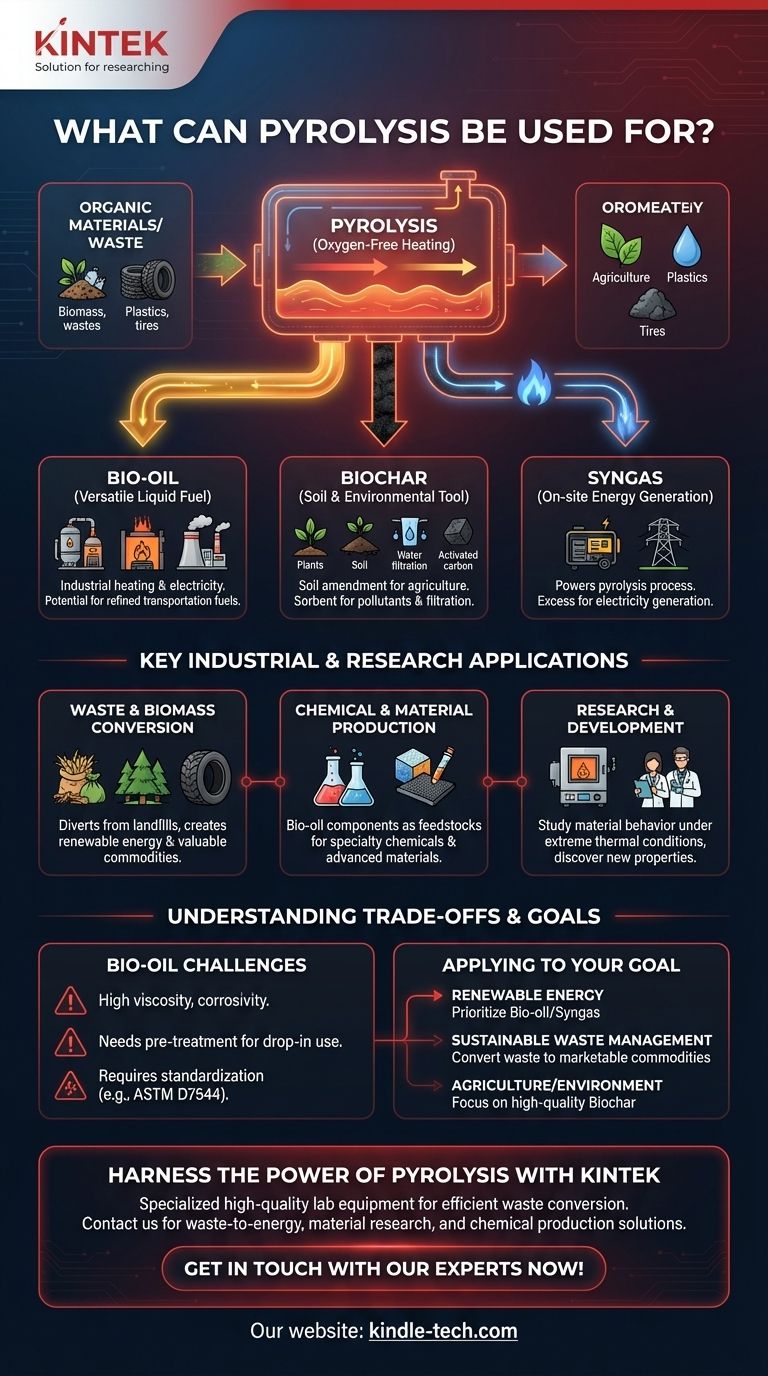

At its core, pyrolysis is a powerful thermochemical process used to convert organic materials and waste into valuable products. By heating substances like biomass, plastics, or old tires in an oxygen-free environment, it breaks them down into a liquid fuel (bio-oil), a solid carbon-rich material (biochar), and a combustible gas (syngas), each with distinct industrial applications.

Pyrolysis is fundamentally a value-creation technology. It transforms low-value or waste materials into marketable products for energy generation, agricultural improvement, and chemical production, positioning it as a key process in waste management and renewable energy sectors.

The Primary Products and Their Uses

Pyrolysis is not a single-output process. The value comes from its ability to create three distinct products simultaneously from a single feedstock. Understanding the application of each is key to understanding the technology's overall utility.

Bio-oil: A Versatile Liquid Fuel

Bio-oil, often called pyrolysis oil, is a liquid fuel that can serve as a substitute for conventional fuel oil in many applications.

It is most commonly used in stationary applications like boilers, furnaces, and large power plants for generating heat and electricity. Industries from steel and iron manufacturing to ceramics factories can utilize it.

With further refinement, bio-oil has the potential to be upgraded within existing refinery infrastructure to produce more conventional hydrocarbon fuels, such as transportation-grade gasoline or diesel.

Biochar: A Powerful Soil and Environmental Tool

Biochar is the solid, charcoal-like residue left after pyrolysis. Its primary and most well-known use is as a soil amendment.

Adding biochar to soil can improve its structure, water retention, and nutrient-holding capacity, leading to better agricultural yields.

Beyond farming, biochar's porous structure makes it an excellent sorbent for pollutants. It is also used as a feedstock for producing highly effective activated carbon for filtration systems.

Syngas: On-site Energy Generation

Syngas, or synthesis gas, is a mixture of combustible gases produced during the process.

Its main application is to be captured and used as a fuel source to power the pyrolysis process itself, making the operation more energy-efficient and self-sustaining.

Excess syngas can also be used to fuel generators to produce electricity, contributing to the overall energy output of the facility.

Key Industrial and Research Applications

Beyond the direct use of its products, the pyrolysis process itself is applied across several key sectors to solve specific challenges.

Waste and Biomass Conversion

Pyrolysis is a cornerstone of "waste-to-energy" and "waste-to-value" strategies. It is highly effective at processing agricultural waste, forestry residues, and post-consumer waste like rubber tires.

This diverts significant volume from landfills while creating renewable energy and valuable commodities, contributing to a more circular economy.

Chemical and Material Production

The chemical components within bio-oil can be extracted and used as feedstocks for producing other specialty chemicals and advanced materials. This is an emerging field that moves pyrolysis beyond just fuel production.

Research and Development

In controlled laboratory settings, pyrolysis furnaces are used by scientists to study how different materials behave and break down under extreme thermal conditions. This research helps improve industrial processes and discover new material properties.

Understanding the Trade-offs and Limitations

While powerful, pyrolysis is not a perfect solution, and its products come with technical challenges that must be managed for successful industrial application.

The Challenge of Bio-oil Quality

The direct industrial use of raw bio-oil is often limited. It tends to have high viscosity, low chemical stability, and can be corrosive to standard pipes and engine components.

These properties mean that bio-oil often requires pre-treatment or upgrading before it can be used as a drop-in replacement for conventional fuels, adding cost and complexity to the process.

The Need for Standardization

To ensure safe and reliable use, standards have been developed. For example, ASTM D7544 regulates the use of pyrolysis oil in stationary burners, but broad adoption across all potential applications is still evolving.

How to Apply This to Your Goal

The best application of pyrolysis depends entirely on your primary objective.

- If your primary focus is renewable energy production: Prioritize the use of bio-oil and syngas in boilers, furnaces, or generators, but be prepared to address the fuel's quality and stability issues.

- If your primary focus is sustainable waste management: Use pyrolysis to convert waste streams like biomass or old tires into marketable commodities, reducing landfill pressure and creating new revenue.

- If your primary focus is agriculture or environmental remediation: Concentrate on producing high-quality biochar to be used as a soil amendment or as a base material for activated carbon filters.

Ultimately, pyrolysis provides a versatile and effective pathway for transforming materials from a liability into an asset.

Summary Table:

| Product | Description | Primary Applications |

|---|---|---|

| Bio-oil | Liquid fuel from pyrolysis | Industrial heating, electricity generation, potential for refined transportation fuels |

| Biochar | Solid, carbon-rich material | Soil amendment, water filtration (activated carbon), pollutant sorption |

| Syngas | Combustible gas mixture | On-site energy for pyrolysis process, excess for electricity generation |

Ready to harness the power of pyrolysis for your laboratory or industrial project?

At KINTEK, we specialize in providing high-quality lab equipment, including pyrolysis furnaces, to help you efficiently convert waste materials like biomass, plastics, and tires into valuable products such as bio-oil, biochar, and syngas. Whether your goal is renewable energy production, sustainable waste management, or agricultural improvement, our solutions are designed to meet your specific needs.

Contact us today to discuss how our expertise and equipment can help you achieve your goals in waste-to-energy conversion, material research, or chemical production. Let's turn your waste streams into assets together!

Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

- Powerful Plastic Crusher Machine

People Also Ask

- What is pyrolysis advantages and disadvantages? Unlocking Waste-to-Value Potential

- What is the effect of pyrolysis? Converting Waste into Fuel, Chemicals, and Energy

- Does pyrolysis contribute to greenhouse gases? A Key Strategy for Net-Zero Emissions

- What is the meaning of rotary furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- Which catalyst used in biomass pyrolysis for production of bio-oil? Select the Right Catalyst for Your Bio-Oil

- What is pyrolysis of biomass to produce hydrogen? A Guide to Carbon-Negative Green Hydrogen

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What is the effect of heating rate in pyrolysis? Control Product Yields for Biochar, Bio-oil, or Syngas