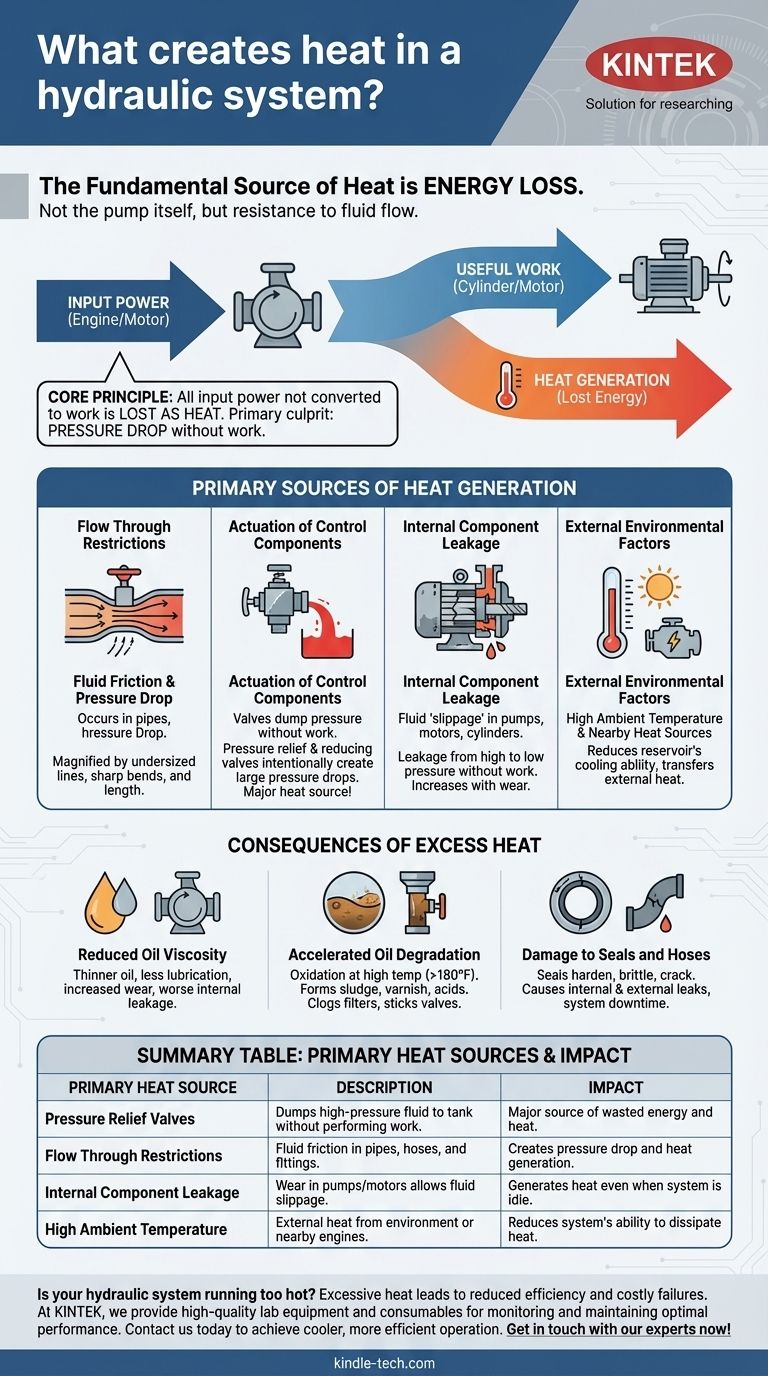

The fundamental source of heat in any hydraulic system is energy loss. Heat is not generated by the pump itself, but by the resistance the hydraulic fluid encounters as it flows through the system. Every time fluid pressure drops without performing useful work—such as moving a cylinder or turning a motor—that lost energy is converted directly into heat.

The core principle is simple: all the power a prime mover puts into a hydraulic system must either be converted into useful work or be lost as heat. The primary mechanism for this energy loss is a pressure drop, which occurs whenever fluid is forced through restrictions like valves, orifices, hoses, and even from internal component leakage.

The Fundamental Principle: Energy Conversion

Understanding heat generation starts with the first law of thermodynamics: energy cannot be created or destroyed, only changed in form. A hydraulic system is simply an energy conversion machine.

From Input Power to Work and Heat

The engine or electric motor provides input power to the hydraulic pump. The pump converts this mechanical energy into hydraulic energy in the form of flow and pressure.

This hydraulic energy has only two possible fates. It either performs useful work (the intended function), or it is lost to inefficiencies. This "lost" energy inevitably converts into thermal energy, or heat.

Why Pressure Drop is the Primary Culprit

A pressure drop is the key indicator of energy being expended. When this pressure drop occurs across an actuator (like a cylinder), work is done.

However, when a pressure drop occurs across a relief valve, a partially closed flow control, or an undersized hose, no work is accomplished. This "wasted" pressure drop represents a direct conversion of hydraulic energy into heat.

Primary Sources of Heat Generation

Every component in a hydraulic circuit contributes to the total system inefficiency, but some are far more significant sources of heat than others.

Flow Through Pipes, Hoses, and Fittings

Fluid flowing through any conductor experiences friction against the walls. This friction creates a pressure drop and, therefore, heat.

This effect is magnified by undersized lines, sharp bends, and excessive length, all of which increase turbulence and resistance to flow.

Actuation of Control Components

Valves are often the largest single source of heat. Pressure relief valves and pressure-reducing valves are designed to intentionally create a large pressure drop to control system pressure.

When a relief valve opens, it dumps high-pressure oil directly to the low-pressure reservoir. Since no work is done, nearly all the energy from that pressure drop becomes heat. Throttling flow through a needle valve has the same effect.

Internal Component Leakage

No hydraulic component is perfectly sealed. Pumps, motors, and cylinders all have minute internal clearances.

High-pressure fluid inevitably leaks or "slips" across these clearances to a low-pressure area. This internal leakage is a form of pressure drop without work, generating a steady amount of heat even when the system is idle. As components wear, this leakage increases, and so does heat generation.

External Environmental Factors

The system's environment also plays a role. High ambient air temperature reduces the reservoir's natural ability to dissipate heat.

Additionally, placing hydraulic components near other heat sources, like a diesel engine, will transfer that external heat into the hydraulic fluid, compounding the internal heat generation.

Understanding the Consequences of Excess Heat

Allowing a hydraulic system to run too hot is not just a sign of inefficiency; it actively damages the system and degrades performance.

Reduced Oil Viscosity

As hydraulic oil heats up, its viscosity (thickness) decreases. Thinner oil lubricates less effectively, increasing mechanical wear on pumps and motors.

It also worsens internal leakage, which in turn generates even more heat, creating a vicious cycle of rising temperature and falling efficiency.

Accelerated Oil Degradation

High temperatures (typically above 180°F or 82°C) dramatically accelerate the oxidation rate of hydraulic oil.

Oxidized oil forms sludge, varnish, and acids. These contaminants clog filters, cause valves to stick, and corrode metal components, leading to premature system failure.

Damage to Seals and Hoses

The elastomeric seals and hoses used throughout a hydraulic system are designed for a specific temperature range.

Excessive heat causes seals to harden, become brittle, and crack. This results in both internal and external fluid leaks, which are a primary cause of system downtime.

Making the Right Choice for Your Goal

Managing heat is about managing energy loss. Your approach should be dictated by your system's primary goal, whether it's peak performance, long-term reliability, or troubleshooting an existing problem.

- If your primary focus is maximum efficiency: Design the system to minimize unnecessary pressure drops by using components like load-sensing pumps and correctly sizing all lines and valves.

- If your primary focus is system longevity: Ensure adequate cooling capacity through properly sized reservoirs and heat exchangers to keep fluid temperatures in the optimal range (120-140°F or 50-60°C).

- If you are troubleshooting an overheating system: Identify the largest pressure drops that are not performing useful work; a constantly open relief valve is the most common culprit.

Ultimately, viewing your hydraulic system through the lens of energy transfer is the key to designing, operating, and maintaining a powerful and reliable machine.

Summary Table:

| Primary Heat Source | Description | Impact |

|---|---|---|

| Pressure Relief Valves | Dumps high-pressure fluid to tank without performing work. | Major source of wasted energy and heat. |

| Flow Through Restrictions | Fluid friction in pipes, hoses, and fittings. | Creates pressure drop and heat generation. |

| Internal Component Leakage | Wear in pumps/motors allows fluid slippage. | Generates heat even when system is idle. |

| High Ambient Temperature | External heat from environment or nearby engines. | Reduces system's ability to dissipate heat. |

Is your hydraulic system running too hot? Excessive heat can lead to reduced efficiency, accelerated oil degradation, and costly component failure. At KINTEK, we specialize in providing high-quality lab equipment and consumables to help you monitor and maintain optimal hydraulic system performance. Our solutions are designed to support laboratory needs for reliability and longevity. Contact us today to discuss how we can help you achieve a cooler, more efficient operation. Get in touch with our experts now!

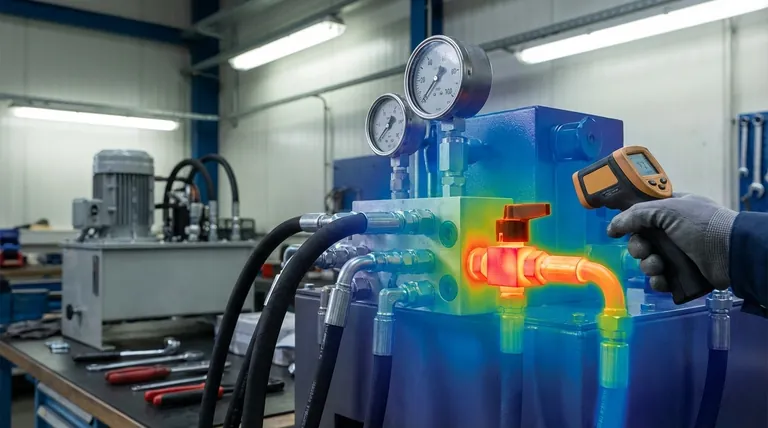

Visual Guide

Related Products

- 100L Chilling Circulator Cooling Water Circulator for Low Temperature Constant Temperature Reaction Bath Water Bath Cooling

- 100L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 5L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- What is the maximum operating temperature of a water based hydraulic fluid? Ensure Fire Safety and System Reliability

- What types of hydraulic press systems are used for research? Discover Pellet, Hot, and Isostatic Solutions

- How do high-precision laboratory hydraulic presses influence PCI? Optimize Gap Design for Nuclear Fuel Safety

- What is the alternative to KBr in IR spectroscopy? Explore Faster, Easier Sample Prep Methods

- How does a laboratory hydraulic press contribute to Fe-Cu-Ni-Sn-VN green bodies? Master High-Density Compaction

- Why is a laboratory hydraulic press required for boron carbide ceramic green bodies? Mastering Precise Pressure Loads

- How many types of power presses are there? A Guide to Mechanical, Hydraulic, and Servo Presses

- What are the advantages of using KBr in IR spectroscopy sample preparation? Achieve Clean, Accurate Spectra