In the world of advanced materials, PVD stands for Physical Vapour Deposition, and CVD stands for Chemical Vapour Deposition. Both are vacuum deposition methods used to apply extremely thin, high-performance coatings to a surface. The fundamental difference is that PVD is a physical process where a material is vaporized and then condenses onto a part, while CVD is a chemical process where gases react on a surface to grow a new layer of material.

The choice between PVD and CVD hinges on one simple distinction: PVD physically "plates" a surface with a vaporized material, much like steam condensing on a cold mirror. In contrast, CVD chemically "grows" a new layer onto the surface from reactive gases.

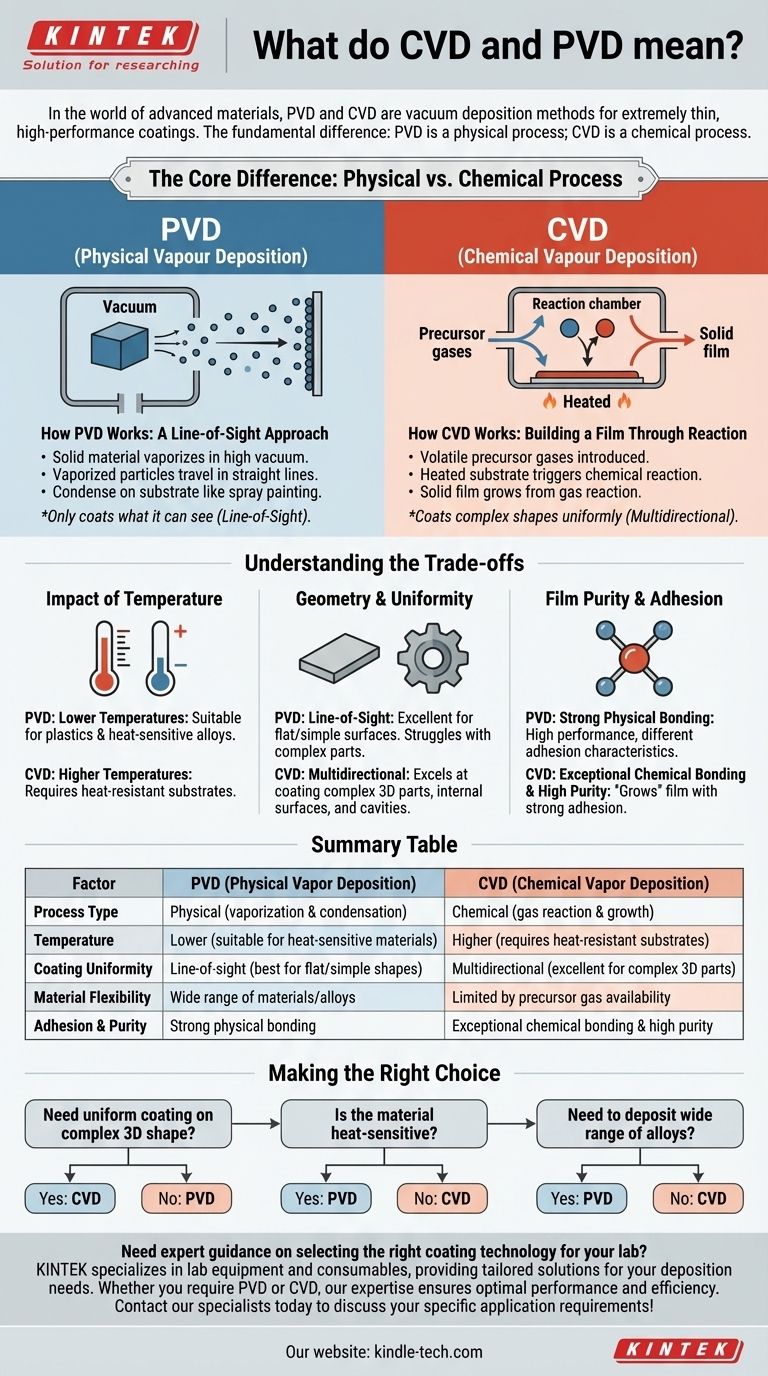

The Core Difference: Physical vs. Chemical Process

To truly understand these techniques, we must look at how each one builds the film atom by atom. The method of delivery and deposition dictates the final properties of the coating and its ideal applications.

How PVD Works: A Line-of-Sight Approach

In Physical Vapour Deposition, the coating material starts as a solid. This solid is vaporized into atoms and molecules inside a high-vacuum chamber.

These vaporized particles then travel in a straight line and physically impact the substrate, condensing on its surface to form the desired thin film. Think of it as a highly controlled form of spray painting, but with individual atoms.

Because the particles travel in a straight line, PVD is a line-of-sight process. Only the surfaces that can be "seen" by the vapor source will be coated.

How CVD Works: Building a Film Through Reaction

Chemical Vapour Deposition begins with volatile precursor gases, not a solid material. These gases are introduced into a reaction chamber containing the substrate.

The substrate is heated to a specific temperature, which provides the energy needed to trigger a chemical reaction between the gases directly on the substrate's surface.

A solid film is one of the byproducts of this reaction, which deposits and grows on the surface. Because the process is driven by gases that can flow around an object, CVD is a multidirectional process capable of coating complex shapes uniformly.

Understanding the Trade-offs

Neither method is universally superior; they are suited for different goals and materials. The choice involves clear trade-offs related to temperature, material compatibility, and the geometry of the part being coated.

The Impact of Temperature

CVD processes often require very high temperatures to initiate the necessary chemical reactions. This can limit the types of materials that can be coated, as the substrate itself must be able to withstand the heat without deforming or melting.

PVD can typically be performed at much lower temperatures, making it suitable for a wider range of substrates, including plastics and heat-sensitive alloys.

Geometry and Uniformity

PVD's line-of-sight nature makes it excellent for coating flat surfaces or simple geometries. However, it struggles to uniformly coat complex, three-dimensional parts with internal surfaces or hidden features.

CVD excels at creating highly uniform (or "conformal") coatings on parts with intricate and complex geometries. The reactive gases can penetrate small cavities and coat all surfaces evenly.

Film Purity and Adhesion

Because CVD "grows" the film through a chemical reaction, it can produce coatings with exceptionally high purity and strong adhesion to the substrate.

PVD coatings are also high-performance, but the physical bonding process can sometimes result in different adhesion characteristics and film densities compared to the chemically bonded films from CVD.

Making the Right Choice for Your Goal

Selecting the correct process requires identifying the most critical outcome for your specific application.

- If your primary focus is coating a complex 3D shape uniformly: CVD is often the superior choice due to its non-line-of-sight, gas-based deposition.

- If your primary focus is coating a heat-sensitive material: PVD is the more suitable process because it operates at significantly lower temperatures.

- If your primary focus is depositing a wide range of materials, including specific alloys: PVD provides greater flexibility in the source materials that can be physically vaporized.

Understanding the fundamental distinction between a physical and chemical process is the key to selecting the right coating technology for your objective.

Summary Table:

| Factor | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (vaporization & condensation) | Chemical (gas reaction & growth) |

| Temperature | Lower (suitable for heat-sensitive materials) | Higher (requires heat-resistant substrates) |

| Coating Uniformity | Line-of-sight (best for flat/simple shapes) | Multidirectional (excellent for complex 3D parts) |

| Material Flexibility | Wide range of materials/alloys | Limited by precursor gas availability |

| Adhesion & Purity | Strong physical bonding | Exceptional chemical bonding & high purity |

Need expert guidance on selecting the right coating technology for your lab? KINTEK specializes in lab equipment and consumables, providing tailored solutions for your deposition needs. Whether you require PVD for heat-sensitive materials or CVD for complex geometries, our expertise ensures optimal performance and efficiency. Contact our specialists today to discuss your specific application requirements!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the process of coating deposition? A Step-by-Step Guide to Thin Film Engineering

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- How do you calculate coating coverage? A Practical Guide to Accurate Material Estimation

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies