At its core, Spark Plasma Sintering (SPS) is an advanced manufacturing technique used to rapidly transform powders into dense, solid materials. It achieves this by simultaneously applying high-amperage pulsed electric current and mechanical pressure within a vacuum, consolidating the material in a single, efficient step. SPS is also known by other names, including Field Assisted Sintering Technique (FAST) and Pulsed Electric Current Sintering (PECS).

The fundamental principle of SPS is using a direct electric current and uniaxial pressure to achieve extremely fast heating and consolidation. This unique combination allows for the creation of advanced materials with superior properties compared to those made with conventional furnace-based methods.

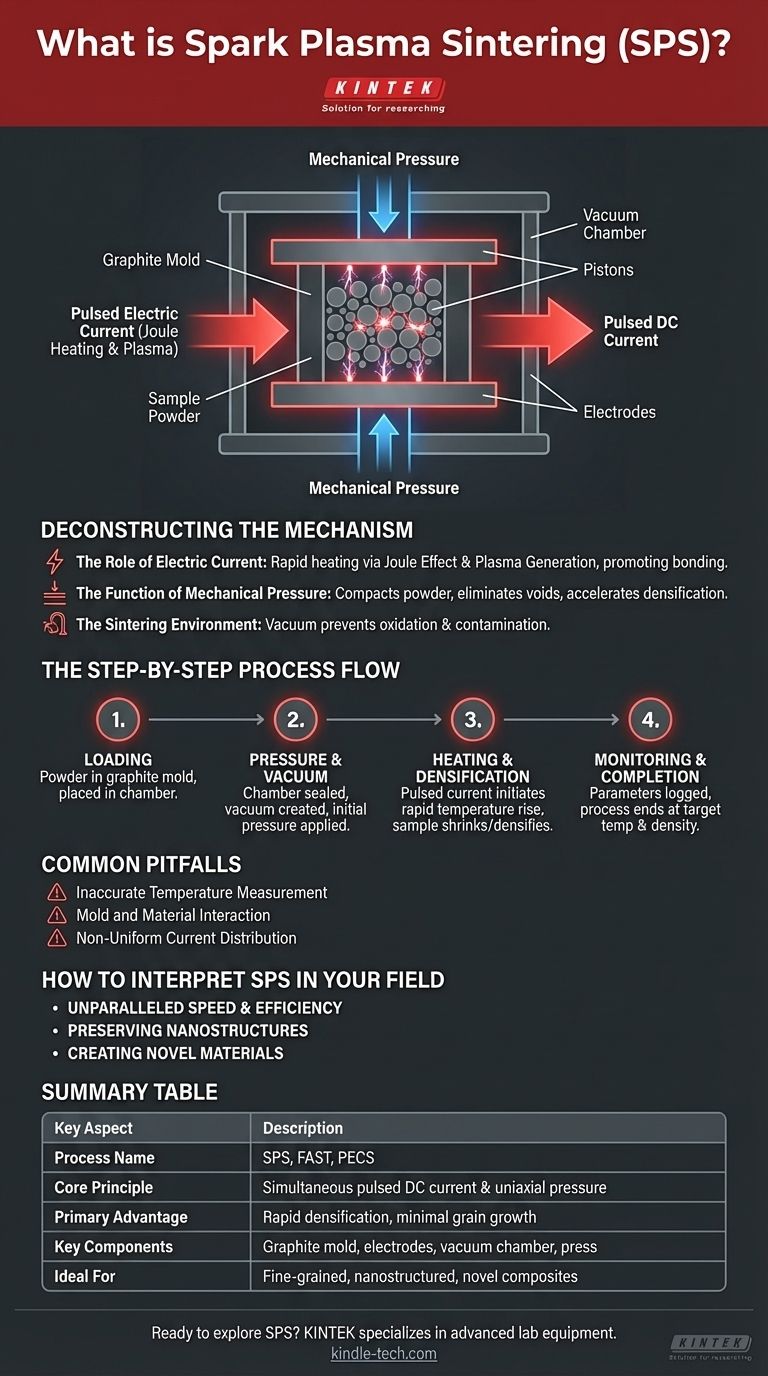

Deconstructing the SPS Mechanism

To understand SPS, it's essential to look at its key components and how they interact to sinter the powdered material. The process relies on a precise synergy between electrical energy, mechanical force, and a controlled environment.

The Core Setup

The sample powder is loaded into a conductive graphite mold. This mold is then positioned between two electrodes (upper and lower) inside a vacuum chamber. This entire assembly is the heart of the SPS machine.

The Role of Electric Current

A high-power, pulsed DC current is passed directly through the electrodes and the graphite mold. This current is responsible for the rapid heating in two primary ways:

- Joule Heating: The graphite mold has electrical resistance, and as the current passes through it, it heats up rapidly, transferring this heat to the powder sample inside.

- Plasma Generation: The electric current can also create spark discharges or plasma in the gaps between individual powder particles. This effect cleans and activates the particle surfaces, promoting superior bonding.

The Function of Mechanical Pressure

While the current is heating the sample, a uniaxial force is applied to the mold via pistons. This constant pressure helps to compact the powder, eliminate voids, and accelerate the densification process as the material softens at high temperatures.

The Sintering Environment

The entire process takes place within a vacuum chamber. Evacuating the chamber removes air and other gases, which prevents oxidation and contamination of the material at the high temperatures required for sintering.

The Step-by-Step Process Flow

The SPS process is highly controlled and automated, with key parameters logged continuously to ensure precision and repeatability.

Loading and Preparation

First, the raw powder is carefully loaded into the graphite mold cavity. The mold is then placed into the SPS chamber, correctly positioned between the upper and lower electrodes.

Applying Pressure and Vacuum

The chamber is sealed, and a vacuum is created. Simultaneously, an initial mechanical pressure is applied through the pistons, compacting the loose powder.

The Heating and Densification Cycle

The pulsed electric current is initiated. The temperature rises at a very high rate, often hundreds of degrees Celsius per minute. As the powder heats and softens, the applied pressure causes the sample to shrink, or densify, as the gaps between particles are eliminated.

Monitoring and Completion

Throughout the cycle, sensors automatically log critical parameters like temperature, applied force, current, voltage, and the vertical movement of the piston (piston travel). The process concludes once the target temperature and maximum density are achieved.

Common Pitfalls to Avoid

While powerful, the effectiveness of the SPS process is highly dependent on precise control and understanding of the materials involved.

Inaccurate Temperature Measurement

Temperature is typically measured on the surface of the graphite mold, not within the sample itself. This can lead to a significant temperature difference between the mold and the powder, requiring careful calibration to avoid overheating or under-sintering the material.

Mold and Material Interaction

The sample material can sometimes react with the graphite mold at high temperatures. This can contaminate the final product or damage the mold. Using protective graphite foils or alternative mold materials is a common solution.

Non-Uniform Current Distribution

If the powder does not conduct electricity uniformly, the current can create "hot spots" within the sample. This leads to uneven densification and can compromise the structural integrity and properties of the final component.

How to Interpret SPS in Your Field

Understanding the core principles of SPS allows you to recognize its potential applications and benefits for specific material goals.

- If your primary focus is speed and efficiency: SPS is unparalleled for its ability to consolidate materials in minutes, compared to the hours or even days required for conventional furnaces.

- If your primary focus is preserving nanostructures: The rapid heating and cooling cycles minimize grain growth, making SPS ideal for producing dense, fine-grained materials with enhanced mechanical properties.

- If your primary focus is creating novel materials: SPS enables the sintering of materials that are difficult or impossible to consolidate with traditional methods, opening the door for new composites and alloys.

Ultimately, Spark Plasma Sintering is a powerful tool that leverages direct energy and force to forge the next generation of high-performance materials.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Name | Spark Plasma Sintering (SPS), also known as FAST or PECS |

| Core Principle | Simultaneous application of pulsed DC current and uniaxial pressure |

| Primary Advantage | Rapid densification (minutes vs. hours/days), minimal grain growth |

| Key Components | Graphite mold, electrodes, vacuum chamber, hydraulic press |

| Ideal For | Creating fine-grained, nanostructured, and novel composite materials |

Ready to explore how Spark Plasma Sintering can advance your material science projects?

KINTEK specializes in advanced lab equipment, including SPS systems, to help you rapidly create dense, high-performance materials with superior properties. Our expertise supports researchers and engineers in developing novel composites and alloys with precise control and efficiency.

Contact our experts today to discuss how SPS technology can benefit your specific application and accelerate your R&D.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Graphite Vacuum Continuous Graphitization Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What is the mechanism of SPS process? A Deep Dive into Rapid, Low-Temperature Sintering

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology

- What are the steps in spark plasma sintering? Achieve Rapid, Low-Temperature Densification

- What is the SPS process of spark plasma sintering? A Guide to Rapid, Low-Temperature Densification

- What is the difference between hot press and SPS? Choose the Right Sintering Method for Your Lab