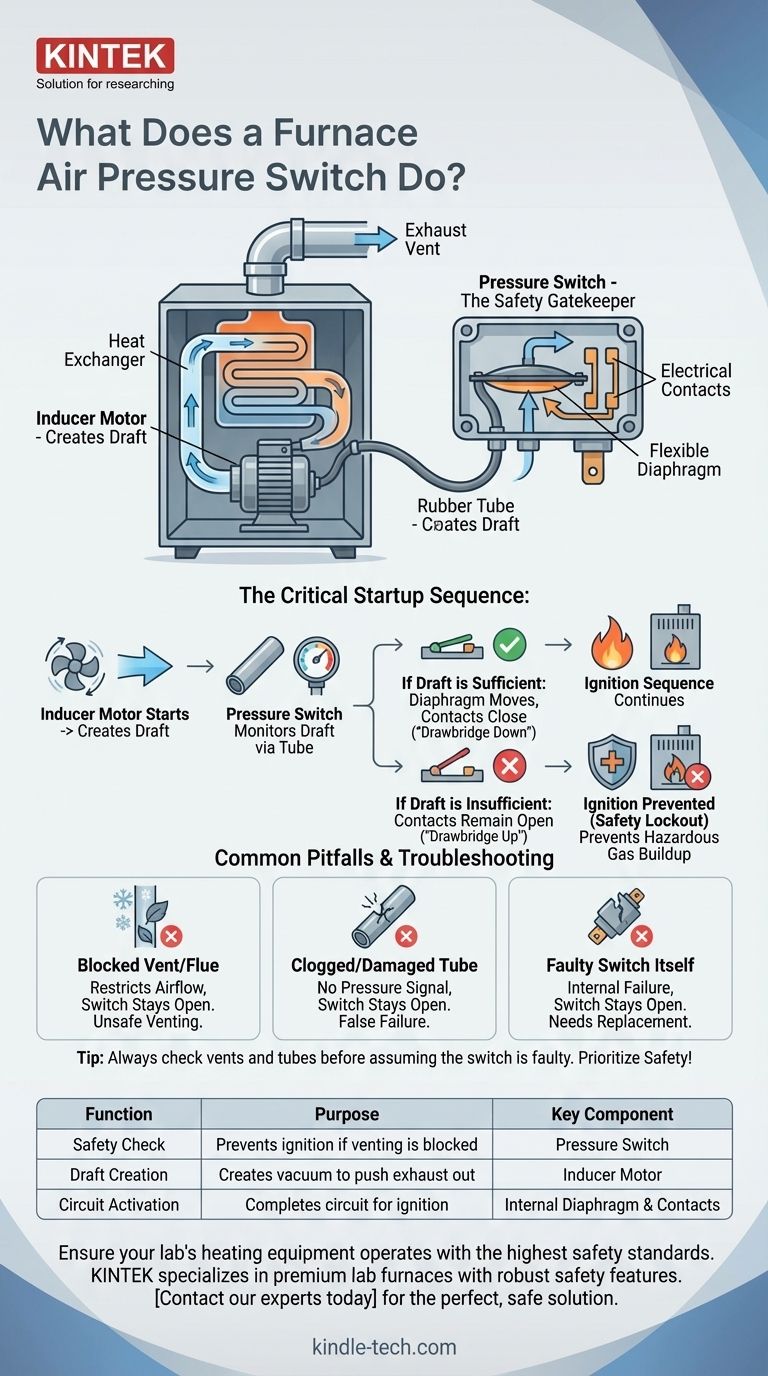

At its core, a furnace air pressure switch is a critical safety device. It acts as a sensor that confirms your furnace's venting system is working correctly before allowing the main burners to ignite. This simple check prevents the furnace from operating if dangerous exhaust gases, like carbon monoxide, cannot be safely removed from your home.

The pressure switch is your furnace's first line of defense against improper venting. It ensures the path is clear for harmful exhaust to exit before the system begins to produce it, preventing both immediate safety hazards and potential damage to the unit.

The Critical Role of a Safety Check

Modern furnaces follow a strict startup sequence to ensure safe operation. The pressure switch is a key checkpoint in this sequence, verifying that the foundation for safe combustion is in place.

Creating the Necessary Draft

Before gas ever flows to the burners, a small fan called an inducer motor turns on. Its job is to create a draft, or a slight vacuum, that actively pulls combustion gases through the heat exchanger and pushes them out the exhaust vent.

Verifying Safe Venting

The pressure switch is connected to the inducer motor assembly by a small rubber tube. It constantly monitors the pressure created by the inducer motor. If the draft is strong enough to create the required negative pressure, the switch activates.

Preventing Dangerous Conditions

If the switch does not detect the proper draft, it will not close the circuit. This action prevents the furnace from proceeding to the ignition stage. This single step is crucial for preventing the buildup of harmful gases, inefficient furnace operation, and even small explosions from unburnt fuel inside the heat exchanger.

How the Pressure Switch Works

The mechanism is simple but effective, functioning much like a gatekeeper for the furnace's ignition sequence. It is an electrical switch that is physically activated by a change in air pressure.

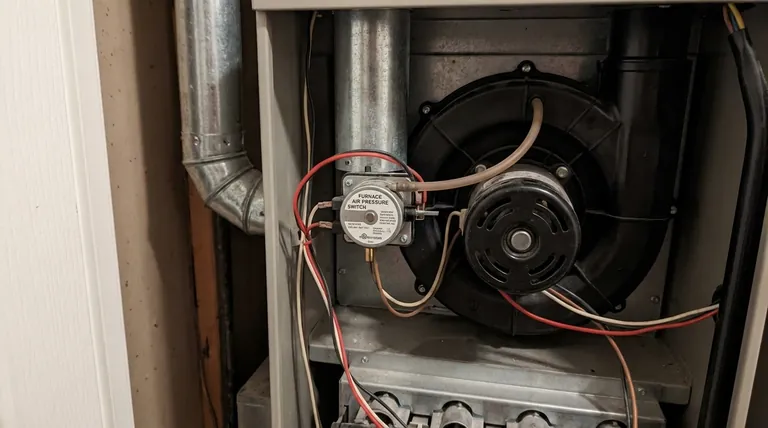

The Inducer Motor and Vacuum Tube

When the inducer motor spins up, it creates suction. This suction pulls air through the small rubber hose connected to the pressure switch.

The Diaphragm and Electrical Contacts

Inside the switch is a flexible rubber diaphragm. The vacuum created by the motor pulls on this diaphragm. If the suction is sufficient, the diaphragm moves enough to press against an internal button or lever.

Completing the Circuit

Pressing this button closes a set of electrical contacts, completing a circuit. Think of it as lowering a drawbridge to allow electricity to pass through to the next component in the startup sequence, which is typically the furnace igniter. If the draft is too weak, the "drawbridge" stays up, and the furnace will not light.

Common Pitfalls and Failure Points

When a furnace fails to ignite, it's easy to blame the pressure switch. However, in many cases, the switch is not faulty; it is correctly doing its job by signaling a genuine problem elsewhere in the system.

A Blocked Vent or Flue

The most common reason for a pressure switch to remain open is a blockage in the furnace's intake or exhaust pipes. This can be caused by snow, ice, leaves, or even an animal's nest, creating a truly unsafe venting condition.

A Clogged or Damaged Tube

The small rubber tube that connects the motor to the switch can become brittle, cracked, or clogged with condensation and debris over time. This prevents the necessary vacuum from reaching the switch's diaphragm, even if the inducer motor is working perfectly.

A Faulty Switch Itself

While less common, the switch itself can fail. The internal diaphragm can become damaged or stuck, or the electrical contacts can wear out, preventing the circuit from closing even when the proper vacuum is present.

Making the Right Choice for Your Goal

Understanding what the pressure switch is telling you is key to diagnosing your furnace correctly and safely.

- If your primary focus is safety: Never bypass a pressure switch. Its failure to close is a clear signal that your furnace has detected a potentially hazardous venting issue that requires immediate investigation.

- If your primary focus is troubleshooting a furnace that won't start: Check for the simplest causes first. Ensure the exterior vent pipes are clear of obstruction and inspect the small rubber hose for cracks or blockages before assuming the switch itself has failed.

Ultimately, this small component empowers you to recognize when your furnace is actively protecting you from a dangerous situation.

Summary Table:

| Function | Purpose | Key Component |

|---|---|---|

| Safety Check | Prevents furnace ignition if venting is blocked | Pressure Switch |

| Draft Creation | Creates a vacuum to push exhaust gases out | Inducer Motor |

| Circuit Activation | Completes electrical circuit for ignition sequence | Internal Diaphragm & Contacts |

Ensure your lab's heating equipment operates with the highest safety standards. KINTEK specializes in premium lab furnaces and related equipment, designed with robust safety features like pressure switches to protect your team and research. Contact our experts today to find the perfect, safe heating solution for your laboratory needs.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What can I use a vacuum pump for? Powering Industrial Processes from Packaging to Automation

- Why does the pressure switch keep tripping on my furnace? Diagnose the Root Cause and Restore Heat

- What is the purpose of the compression chamber in a vacuum pump? The Heart of Vacuum Generation

- What is the role of a two-stage rotary vane vacuum pump in magnesium alloy sublimation? Enhance Efficiency and Purity

- What role do agate grinding balls play in wet ball milling of silicon nitride? Ensure High Purity & Uniform Dispersion

- Why do we use Rotavapor? For Gentle, Efficient Solvent Removal in Your Lab

- What technical considerations are involved in selecting quartz reaction tubes for biomass pyrolysis? Optimize Efficiency

- What are the sources of sputtering? A Guide to the Target and Ion Source