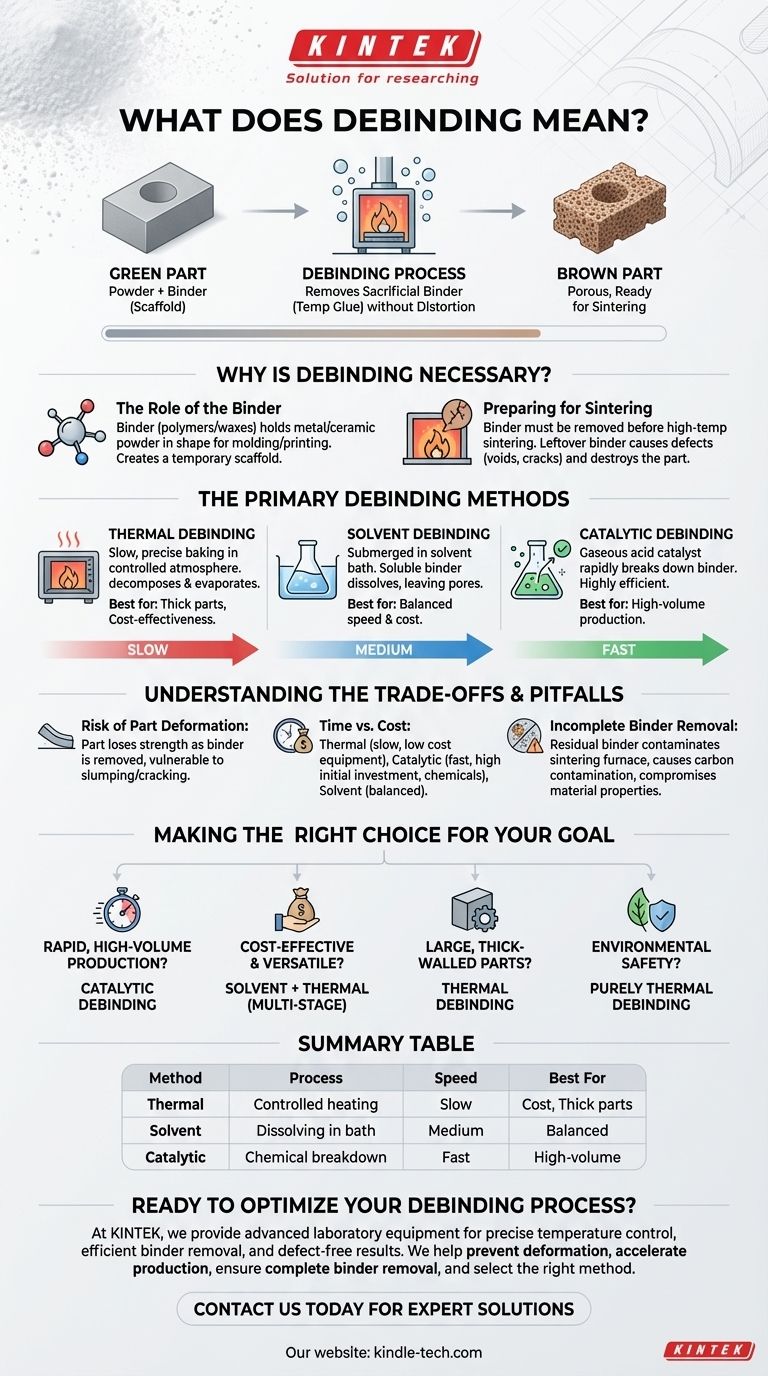

In short, debinding is the critical manufacturing step where a temporary "glue," known as a binder, is removed from a molded or printed part. This process is essential for parts made from metal or ceramic powders, preparing them for the final strengthening step called sintering. It carefully removes the sacrificial binder material without distorting the part's delicate geometry.

The core challenge of debinding is to meticulously extract a temporary binder that gives a part its initial shape, transforming it from a fragile "green part" into a porous "brown part" ready for final densification, all while preventing cracks, slumping, or other defects.

Why is Debinding Necessary?

The Role of the Binder

In processes like Metal Injection Molding (MIM) or binder jetting, fine metal or ceramic powder cannot hold a complex shape on its own. A binder, typically a mix of polymers and waxes, is added to the powder to create a feedstock that can be molded or printed.

The binder acts as a temporary scaffold, holding the powder particles together in the desired shape. This initial, binder-filled component is called a "green part."

Preparing for Sintering

The ultimate goal is to fuse the metal or ceramic particles into a solid, dense object through a high-temperature process called sintering.

The binder must be removed before sintering. If it were left in, it would burn off uncontrollably at high temperatures, releasing gases that would create voids, cracks, and defects, ultimately destroying the part. Debinding clears the way for the particles to bond directly.

The Primary Debinding Methods

The choice of method depends on the binder material, part geometry, and production requirements. Often, a multi-stage process combining methods is used.

Thermal Debinding

This is the most common method, essentially a very slow and precise baking process. The green part is heated in a controlled-atmosphere furnace to temperatures that cause the binder to decompose and evaporate.

The process must be slow to allow the gaseous byproducts to escape through the part's pore network without building up pressure and causing defects.

Solvent Debinding

In this method, the green part is submerged in a solvent bath. The solvent dissolves the soluble components of the binder system, leaving behind a network of open pores.

This process is often faster than purely thermal debinding and is used as a first step. A secondary thermal debinding stage is still required to remove the remaining, insoluble binder elements.

Catalytic Debinding

This is a highly efficient chemical process where a gaseous acid catalyst, like nitric acid, is introduced into a low-temperature oven. The catalyst rapidly breaks down the primary binder polymer (typically polyacetal).

Catalytic debinding is significantly faster than other methods but requires more specialized equipment and binder materials.

Understanding the Trade-offs and Pitfalls

The Risk of Part Deformation

Debinding is the stage where a part is most vulnerable. As the binder is removed, the part loses strength and can easily slump, crack, or distort under its own weight if not properly supported.

This is especially true for parts with thin walls, sharp corners, or complex internal features. The rate of binder removal must be carefully managed to maintain structural integrity.

Time vs. Cost

Thermal debinding is generally the most cost-effective in terms of equipment but is also the slowest, sometimes taking days for large or thick parts.

Catalytic debinding is the fastest but requires a higher initial investment in specialized furnaces and involves handling corrosive chemicals, increasing operational costs. Solvent debinding sits in the middle, offering a speed advantage over thermal but with the added cost and environmental considerations of solvent handling and disposal.

Incomplete Binder Removal

If the debinding process is incomplete, residual binder can contaminate the furnace during sintering, leading to carbon contamination in the final part. This can severely compromise the material's mechanical properties, such as strength and ductility.

Making the Right Choice for Your Goal

- If your primary focus is rapid, high-volume production: Catalytic debinding is the superior choice, as its speed drastically reduces cycle times.

- If your primary focus is cost-effectiveness for a wide range of materials: A multi-stage process starting with solvent and finishing with thermal debinding offers a balanced approach.

- If your primary focus is processing large, thick-walled parts: A slow, carefully controlled thermal debinding cycle is often the only way to prevent internal defects.

- If your primary focus is environmental safety and minimal chemical handling: Purely thermal debinding avoids the complexities of solvent or acid catalyst management.

Ultimately, mastering the debinding process is essential to unlocking the full potential of powder-based manufacturing.

Summary Table:

| Method | Process | Speed | Best For |

|---|---|---|---|

| Thermal Debinding | Controlled heating to decompose binder | Slow | Cost-effectiveness, thick parts |

| Solvent Debinding | Dissolving binder in chemical bath | Medium | Balanced speed and cost |

| Catalytic Debinding | Chemical breakdown using acid catalyst | Fast | High-volume production |

Ready to optimize your debinding process?

At KINTEK, we specialize in providing advanced laboratory equipment and consumables tailored for metal and ceramic manufacturing. Whether you're working with Metal Injection Molding (MIM), binder jetting, or other powder-based processes, our solutions ensure precise temperature control, efficient binder removal, and defect-free results.

We help you:

- Prevent part deformation and defects with controlled thermal debinding systems

- Accelerate production cycles with efficient catalytic and solvent debinding solutions

- Achieve complete binder removal to avoid contamination during sintering

- Select the right debinding method for your specific materials and part geometries

Contact us today to discuss how our expertise in lab equipment can enhance your debinding process and improve your final product quality. Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the role of a vacuum drying oven in Alloy 690TT preparation? Secure Flawless Data Baselines

- What is the use of a pyrolysis plant? Transform Waste into Fuel and Valuable Products

- What role does a vacuum drying oven play in processing Al2O3/ZrO2 ceramic mixed slurries? Ensure Powder Quality

- Why is a vacuum drying oven necessary for Li2MnSiO4 processing? Ensure High Purity & Battery Performance

- Why is a vacuum drying oven recommended for processing wet gels of Erbium-doped titanium dioxide? | KINTEK

- What are the applications of industrial furnace? From Aerospace to Everyday Manufacturing

- How thick is the plasma nitriding layer? Tailor Case Depth from 0.05mm to 0.5mm for Your Needs

- What are the major products from biomass pyrolysis? Tune Your Process for Biochar, Bio-oil, or Gas