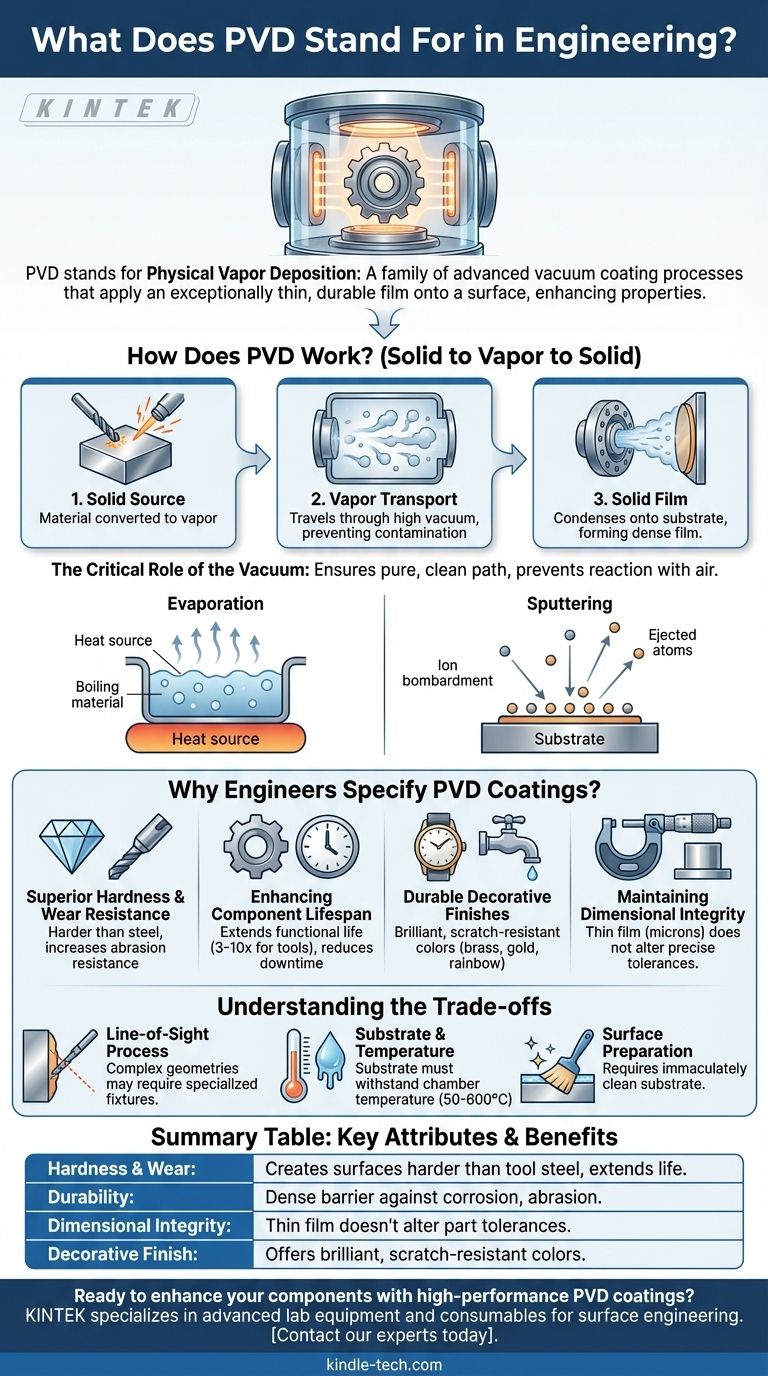

In engineering and manufacturing, PVD stands for Physical Vapor Deposition. It is a family of advanced vacuum coating processes used to apply an exceptionally thin but highly durable film onto the surface of a component, fundamentally enhancing its properties without changing its underlying structure.

Physical Vapor Deposition is not merely a coating; it is a surface engineering technique. It transforms a standard material into a high-performance version by bonding a new, functional surface to it at a near-atomic level.

How Does Physical Vapor Deposition Work?

To understand why PVD is so effective, you must first grasp its fundamental principles. The entire process takes place inside a high-vacuum chamber, which is a critical element.

The Core Principle: Solid to Vapor to Solid

At its heart, PVD involves three steps. First, a solid source material (like titanium, chromium, or aluminum) is converted into a vapor. Second, this vapor travels through the vacuum chamber. Third, it condenses onto the target components, forming a thin, dense, and tightly bonded film.

The Critical Role of the Vacuum

The process must occur in a vacuum to prevent the vaporized coating material from reacting with air. If particles of oxygen or nitrogen were present, they would contaminate the film, compromising its integrity and adhesion. The vacuum ensures a pure, clean path from the source to the substrate.

Two Primary Methods: Evaporation and Sputtering

While there are many variations, most PVD processes fall into two main categories.

Evaporation uses heat to "boil" the source material until it evaporates. Sputtering uses a different approach, bombarding the source material with high-energy ions, which physically knock atoms off the surface like microscopic billiard balls.

Why Do Engineers Specify PVD Coatings?

Engineers choose PVD not for its own sake, but for the specific, high-value problems it solves. The resulting coatings provide benefits that are difficult or impossible to achieve with other methods like painting or traditional electroplating.

Unlocking Superior Hardness and Wear Resistance

PVD coatings like Titanium Nitride (TiN) or Chromium Nitride (CrN) are extremely hard—often harder than the steel substrate they are applied to. This dramatically increases a component's resistance to abrasion, erosion, and galling, making it ideal for cutting tools, molds, and bearings.

Enhancing Component Lifespan

By creating a durable barrier against wear and corrosion, PVD coatings can significantly extend the functional life of a part. A PVD-coated drill bit, for example, can last three to ten times longer than an uncoated one, reducing downtime and replacement costs.

Achieving Durable Decorative Finishes

PVD is also used to create brilliant, durable decorative finishes. Because the film is so tough, it provides colors (from brass and gold tones to black, blue, and rainbow effects) that are far more resistant to scratching and fading than paint or traditional plating. You see this on high-end watches, faucets, and architectural hardware.

Maintaining Dimensional Integrity

The films are incredibly thin, typically just a few microns (thousandths of a millimeter). This means the coating process adds negligible material and does not alter the precise dimensions or tolerances of the underlying part, a critical factor for high-precision components like engine parts or medical implants.

Understanding the Trade-offs and Limitations

While powerful, PVD is not a universal solution. An effective technical advisor must also consider its limitations to make an informed decision.

It Is a Line-of-Sight Process

The vaporized material travels in a relatively straight line from the source to the substrate. This means any surface that is "hidden" or blocked—such as the inside of a long, narrow tube—will not receive an even coating. Complex parts often require specialized fixtures and rotation to ensure uniform coverage.

Substrate and Temperature Considerations

PVD processes generate heat, and the substrate must be able to withstand the chamber temperature, which can range from 50°C to over 600°C depending on the specific method and coating. This makes it unsuitable for many low-melting-point plastics and requires careful management for temperature-sensitive metals.

Surface Preparation is Paramount

The success of PVD is entirely dependent on the cleanliness of the substrate. The component surface must be immaculately clean, free of oils, oxides, and any other contaminants. This often requires a multi-stage, intensive cleaning process that adds cost and complexity to the manufacturing workflow.

Making the Right Choice for Your Application

Selecting the right surface treatment requires a clear understanding of your primary goal. PVD is a performance-driven choice, not a low-cost alternative.

- If your primary focus is maximum wear resistance and tool life: PVD is an excellent choice for cutting tools, forming dies, and high-wear components where performance justifies the cost.

- If your primary focus is corrosion resistance in a challenging environment: The dense, non-porous nature of PVD coatings provides an inert barrier that can significantly outperform many other coating types.

- If your primary focus is a durable, high-end decorative finish: PVD offers a wide range of colors with far greater scratch resistance and longevity than paint or simple plating.

- If your component has complex internal geometries: Carefully evaluate the line-of-sight limitation and consider alternative processes like Chemical Vapor Deposition (CVD) or electroless nickel plating.

Ultimately, understanding PVD empowers you to strategically enhance a component's surface properties without compromising its core structural integrity.

Summary Table:

| Key Attribute | PVD Coating Benefit |

|---|---|

| Hardness & Wear | Creates surfaces harder than tool steel, extending component life by 3-10x. |

| Durability | Provides a dense, non-porous barrier against corrosion, abrasion, and fading. |

| Dimensional Integrity | Applies a thin film (a few microns) that doesn't alter part tolerances. |

| Decorative Finish | Offers brilliant, scratch-resistant colors for high-end applications. |

Ready to enhance your components with high-performance PVD coatings? KINTEK specializes in advanced lab equipment and consumables for surface engineering. Our solutions help you achieve superior wear resistance, extended part lifespan, and durable decorative finishes. Contact our experts today to discuss how our PVD technology can meet your specific laboratory and manufacturing needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

People Also Ask

- What is the RF frequency for sputtering? Unlocking the Standard for Insulating Materials

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained

- What is deposition in environmental chemistry? Understanding How Air Pollution Harms Ecosystems

- Is sputtering a PVD? Discover the Key Coating Technology for Your Lab

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials