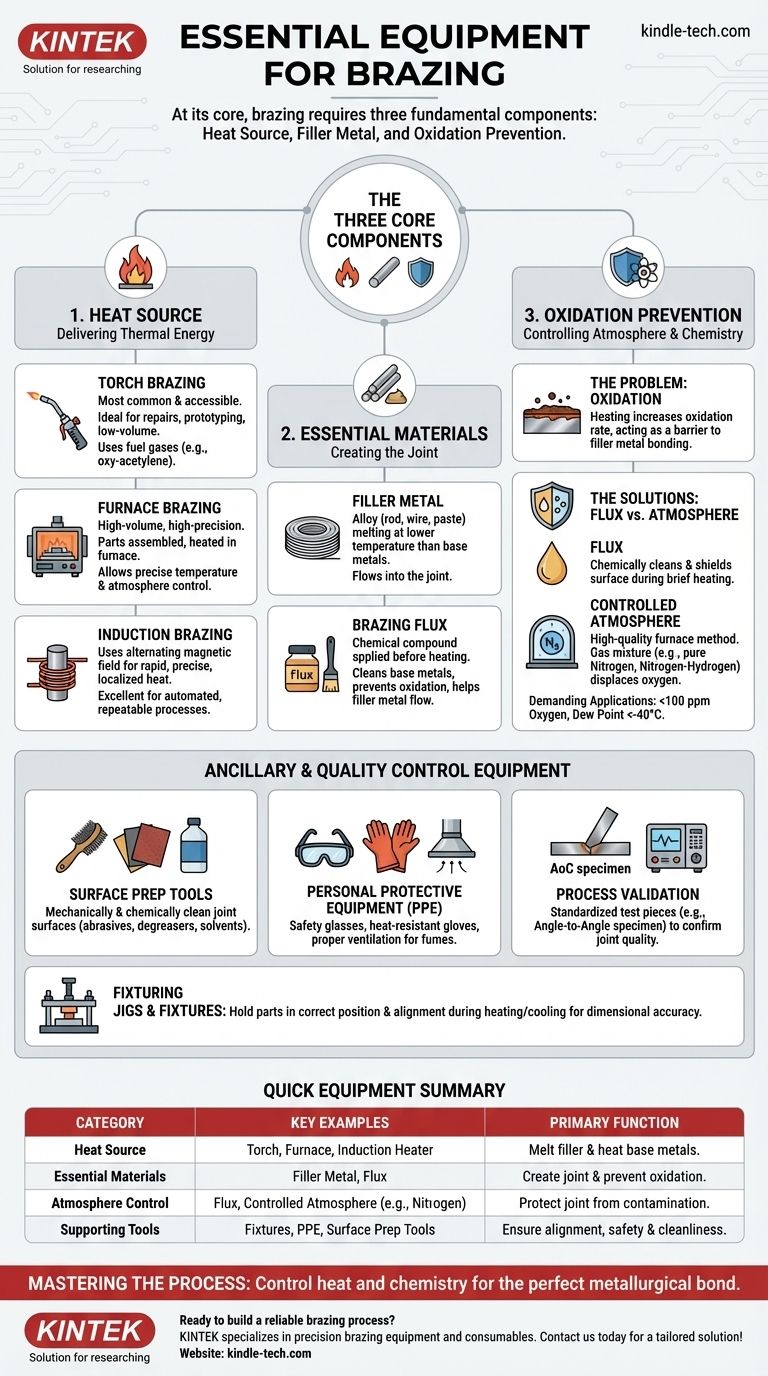

At its core, brazing requires three fundamental components: a source of heat, a filler metal, and a method to prevent oxidation, which is typically a flux or a controlled atmosphere. The specific equipment you need is dictated entirely by the materials you are joining, the scale of your production, and the quality standards you must meet.

The central challenge in any brazing operation is applying clean, controlled heat to the base metals. Your choice of equipment—from a simple hand-held torch to a sophisticated controlled-atmosphere furnace—is fundamentally a decision about how to best manage that heat and protect the joint from contamination.

The Core Components of a Brazing Setup

Every brazing operation, regardless of its complexity, is built around a few essential pieces of equipment and materials. Understanding their individual roles is the first step to building a reliable process.

The Heat Source: Delivering Thermal Energy

The primary tool in brazing is what provides the heat to melt the filler metal. The options range widely in complexity and cost.

Torch Brazing is the most common and accessible method. It uses a flame from a hand-held torch, making it ideal for repairs, prototyping, and low-volume production. Common fuel gas combinations include air-propane, air-acetylene, and oxy-acetylene.

Furnace Brazing is used for high-volume, high-precision work. Parts are assembled with the filler metal pre-placed and then heated in a furnace. This method allows for precise temperature control and often takes place in a controlled atmosphere to prevent oxidation.

Induction Brazing uses an alternating magnetic field to induce an electric current in the parts, generating heat rapidly and precisely. This is excellent for automated, repeatable processes where heating needs to be localized.

Essential Materials: Filler and Flux

These consumable materials are what create the brazed joint itself.

A brazing filler metal is the alloy (often in the form of a rod, wire, or paste) that melts and flows into the joint. Its melting point must be lower than that of the base metals being joined.

A brazing flux is a chemical compound applied to the joint area before heating. It cleans the base metals, protects them from oxidation during heating, and helps the molten filler metal flow into the joint.

Fixturing: Ensuring Proper Alignment

Jigs and fixtures are mechanical devices used to hold the component parts in the correct position and alignment during the heating and cooling cycle. Proper fixturing is critical for maintaining dimensional accuracy.

The Critical Role of Atmosphere Control

The most significant challenge at brazing temperatures is oxidation, where the hot metal reacts with oxygen in the air. This forms a layer that prevents the filler metal from properly wetting and bonding with the base materials.

The Problem of Oxidation

As metals are heated, their rate of oxidation increases dramatically. This oxide layer acts as a barrier, and if not removed and prevented from re-forming, it will result in a weak or failed joint.

Solving Oxidation: Flux vs. Atmosphere

You have two primary tools to combat oxidation: chemical (flux) or environmental (controlled atmosphere).

Using flux is common in torch brazing. It chemically cleans the surface and shields it during the brief heating cycle.

A controlled atmosphere is the method of choice for high-quality furnace brazing, especially with reactive materials like aluminum. The furnace is filled with a specific gas mixture that displaces the oxygen.

For demanding applications, such as manufacturing aluminum heat exchangers, the atmosphere must be exceptionally pure. The environment must be an inert or reducing gas, such as pure nitrogen or a nitrogen-hydrogen blend, with an oxygen content below 100 parts per million (ppm) and extremely low humidity, often with a dew point below -40°C.

Ancillary and Quality Control Equipment

Beyond the core components, a professional setup includes tools for preparation, safety, and validation.

Surface Preparation Tools

Before brazing, the joint surfaces must be mechanically and chemically clean. This may require abrasives like wire brushes or sandpaper, as well as chemical degreasers and solvents.

Personal Protective Equipment (PPE)

Safety is non-negotiable. Essential PPE includes heat-resistant gloves, safety glasses with the appropriate shade for brazing, and proper ventilation to remove fumes, especially when using flux.

Process Validation Specimens

In industrial settings, processes must be validated. Standardized test pieces, like an angle-to-angle (AoC) specimen, are often brazed alongside production parts to confirm the quality and strength of the joints without destroying the actual product.

Making the Right Choice for Your Goal

Your equipment selection should be driven by the specific demands of your project.

- If your primary focus is on repairs, prototyping, or one-off projects: A simple torch, filler metal, and flux provide the most cost-effective and flexible solution.

- If your primary focus is on repeatable, high-volume production of simple parts: An induction heating setup offers unmatched speed and consistency.

- If your primary focus is on complex assemblies or joining reactive metals like aluminum at scale: A controlled atmosphere furnace is the only way to achieve the necessary cleanliness and joint integrity.

Ultimately, mastering brazing is about controlling heat and chemistry to create a perfect metallurgical bond.

Summary Table:

| Equipment Category | Key Examples | Primary Function |

|---|---|---|

| Heat Source | Torch, Furnace, Induction Heater | Melt the filler metal and heat the base metals. |

| Essential Materials | Filler Metal, Flux | Create the joint and prevent oxidation. |

| Atmosphere Control | Flux, Controlled Atmosphere (e.g., Nitrogen) | Protect the joint from contamination during heating. |

| Supporting Tools | Fixtures, PPE, Surface Prep Tools | Ensure alignment, safety, and joint cleanliness. |

Ready to build a reliable brazing process? The right equipment is key to achieving strong, clean, and repeatable joints. At KINTEK, we specialize in providing the lab equipment and consumables you need for precision brazing, from furnaces for controlled atmosphere work to essential materials. Let our experts help you select the perfect setup for your materials and production scale.

Contact KINTEL today to discuss your brazing application and get a tailored solution!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- What is the sintering process of powder metallurgy? Transform Powder into Durable Metal Parts

- Where is vacuum furnace used? Essential for Aerospace, Medical, and High-Tech Manufacturing