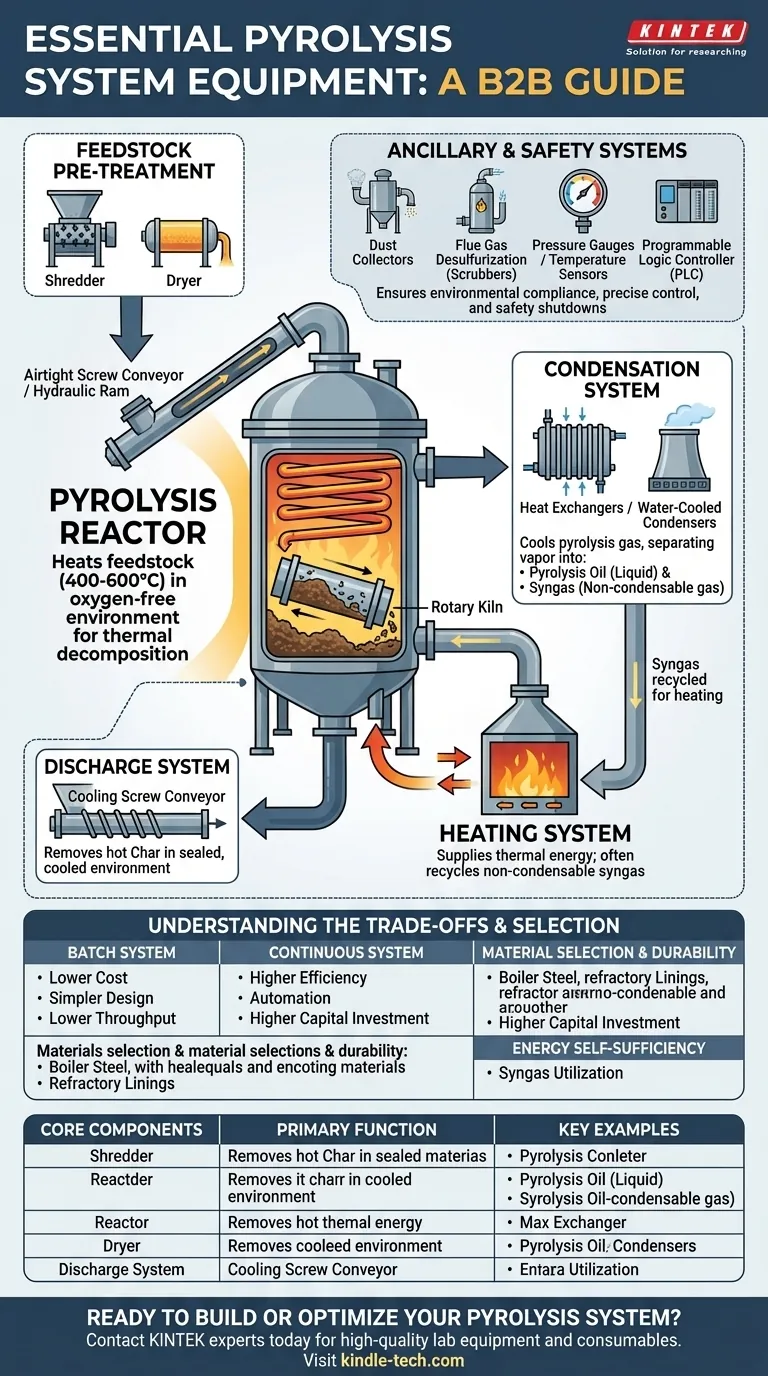

At its core, a pyrolysis system requires four essential pieces of equipment. These are the pyrolysis reactor where the material is heated, a feeding system to introduce the material, a heating system to supply the energy, and a condensation system to cool the resulting gas into liquid oil. These components work together to thermally decompose organic material in an oxygen-free environment.

A successful pyrolysis plant is not just a collection of parts, but a fully integrated system. The true challenge lies in ensuring these components work in unison to precisely control material flow and heat transfer in an oxygen-deprived atmosphere, which is essential for both safety and product quality.

The Core Components of a Pyrolysis Plant

Understanding the function of each primary piece of equipment is the first step in grasping how a pyrolysis system operates as a whole. Each component solves a specific engineering challenge in the process.

The Pyrolysis Reactor: The Heart of the Operation

The reactor is the sealed, oxygen-free vessel where the feedstock is heated to high temperatures (typically 400-600°C) and undergoes thermal decomposition.

The choice of reactor design is one of the most critical decisions. Common types include rotary kilns, which tumble the material for even heating and are ideal for continuous processing, and fixed-bed reactors, which are simpler and often used for batch operations.

The Feeding System: Controlled Material Input

The feeding system's primary job is to get feedstock into the sealed reactor without introducing oxygen, which would cause combustion instead of pyrolysis.

This is typically achieved with equipment like an airtight screw conveyor or a hydraulic ram. The system must be robust and create a reliable seal against the high temperatures and pressures inside the reactor.

The Heating System: The Energy Source

This system provides the thermal energy required to drive the pyrolysis reaction. The design must ensure consistent and controllable heat distribution throughout the reactor.

Most modern systems burn a fuel source in a separate combustion chamber to heat the exterior of the reactor. Critically, a portion of the non-condensable syngas produced during pyrolysis is often recycled back to this chamber, making the system partially self-sustaining.

The Condensation System: Capturing the Value

As the feedstock breaks down, it creates a hot vapor known as pyrolysis gas. The condensation system is designed to cool this gas rapidly.

This cooling process separates the gas stream into two primary products: a condensable liquid (pyrolysis oil) and non-condensable gases (syngas). This typically involves a series of heat exchangers or condensers, often cooled by a water-circulating cooling tower.

The Discharge System: Removing Solid Byproducts

After the reaction is complete, a solid residue called char (often referred to as carbon black) remains. The discharge system removes this material from the reactor safely.

Because the char is extremely hot, it must be cooled in a sealed environment, like a cooling screw conveyor, to prevent it from igniting upon contact with air.

Ancillary and Safety Equipment: Beyond the Basics

A functional plant requires more than just the core components. Supporting systems are crucial for efficiency, safety, and regulatory compliance.

Feedstock Pre-treatment

Most raw materials aren't ready for the reactor. Pre-treatment equipment often includes shredders to reduce particle size for better heat transfer and dryers to remove moisture, which can hinder the process and lower oil quality.

Environmental Control Systems

Pyrolysis plants must manage emissions. This requires equipment like dust collectors for material handling and flue gas desulfurization systems (scrubbers) to treat the exhaust from the heating chamber before it's released.

Safety and Control Systems

Operating at high temperatures and pressures demands robust safety measures. This includes an array of pressure gauges, temperature sensors, emergency vents, and an automated Programmable Logic Controller (PLC) to monitor the entire system and trigger safety shutdowns if necessary.

Understanding the Trade-offs

Selecting equipment involves balancing cost, efficiency, and operational complexity. There is no single "best" setup; the optimal choice depends on the project's scale and goals.

Batch vs. Continuous Systems

A batch system processes one load at a time, requiring cooling, emptying, and reloading between cycles. It has a lower initial cost and simpler design but suffers from lower throughput and higher labor costs.

A continuous system runs without interruption, with feedstock constantly fed in and byproducts constantly removed. It offers high efficiency and automation but demands a significantly higher capital investment and more sophisticated engineering.

Material Selection and Durability

The extreme conditions inside a pyrolysis reactor demand specialized materials. The reactor is typically built from high-temperature resistant boiler steel (like Q245R or Q345R) and may include internal refractory linings to withstand corrosive elements and prevent heat loss. Investing in durable materials prevents costly downtime and premature failure.

Energy Self-Sufficiency

A key goal for many plants is to use the syngas produced to power the heating system, reducing external energy costs. While this creates a highly efficient loop, it requires a stable process that generates consistent quality syngas and a reliable system to purify and deliver that gas back to the burners.

Choosing the Right Equipment for Your Goal

Your selection of pyrolysis equipment should be dictated entirely by your operational objectives.

- If your primary focus is small-scale research or proof-of-concept: A simple, manually operated batch reactor is the most practical and cost-effective starting point.

- If your primary focus is commercial-scale waste processing: A fully automated, continuous system with robust pre-treatment and environmental controls is essential for achieving the throughput and regulatory compliance needed for profitability.

- If your primary focus is maximizing high-quality liquid fuel output: The design of your condensation and cooling system is just as critical as the reactor, as it directly controls the efficiency of vapor-to-liquid recovery.

Ultimately, the right equipment is a complete, integrated system engineered to match your specific feedstock, desired output, and operational scale.

Summary Table:

| Core Component | Primary Function | Key Examples |

|---|---|---|

| Pyrolysis Reactor | Heats feedstock in an oxygen-free environment | Rotary Kiln, Fixed-Bed Reactor |

| Feeding System | Introduces material without letting oxygen in | Airtight Screw Conveyor, Hydraulic Ram |

| Heating System | Supplies thermal energy for decomposition | Combustion Chamber (often using syngas) |

| Condensation System | Cools vapor into liquid oil and syngas | Heat Exchangers, Water-Cooled Condensers |

Ready to build or optimize your pyrolysis system? The right equipment is critical for safety, efficiency, and product quality. KINTEK specializes in high-quality lab equipment and consumables for pyrolysis research and development. Whether you're scaling up from a batch reactor or need robust components for a continuous plant, our expertise can help you achieve precise temperature control and reliable performance. Contact our experts today to discuss how we can support your laboratory's specific pyrolysis needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

People Also Ask

- Can aluminum be sputtered? Master the Process for High-Quality Thin Films

- What is the primary function of a high-speed magnetic stirrer in the synthesis of Pd-on-Au NPs? Ensure Uniform Diffusion

- What is the function of high-temperature thermal treatment equipment in TiO2/G nanocomposites? Optimize Photocatalysts

- What is the purpose of a rotavap? Achieve Gentle, Efficient Solvent Removal for Your Lab

- Do cannabinoids evaporate? How to Preserve Potency and Prevent Degradation

- What happens to steel after annealing? Unlock Superior Machinability and Formability

- What is the purpose of a constant temperature incubator shaker? Master Quercetin Adsorption on Nanocomposites

- How do you measure melting? Mastering Temperature & Rate for Lab & Industry