The most critical factors in choosing a laboratory vacuum pump are your specific application, the required vacuum level, and the chemical compatibility of the pump's materials. These three elements will dictate whether you need a simple dry pump for filtration or a more powerful oil-sealed pump for high-vacuum processes like freeze-drying. Understanding how they interrelate is the key to avoiding a costly or inefficient choice.

Selecting a vacuum pump is not about finding the most powerful model, but about precisely matching the pump's technology to your scientific task. The decision ultimately balances the required vacuum depth against the risks of contamination and the need for maintenance.

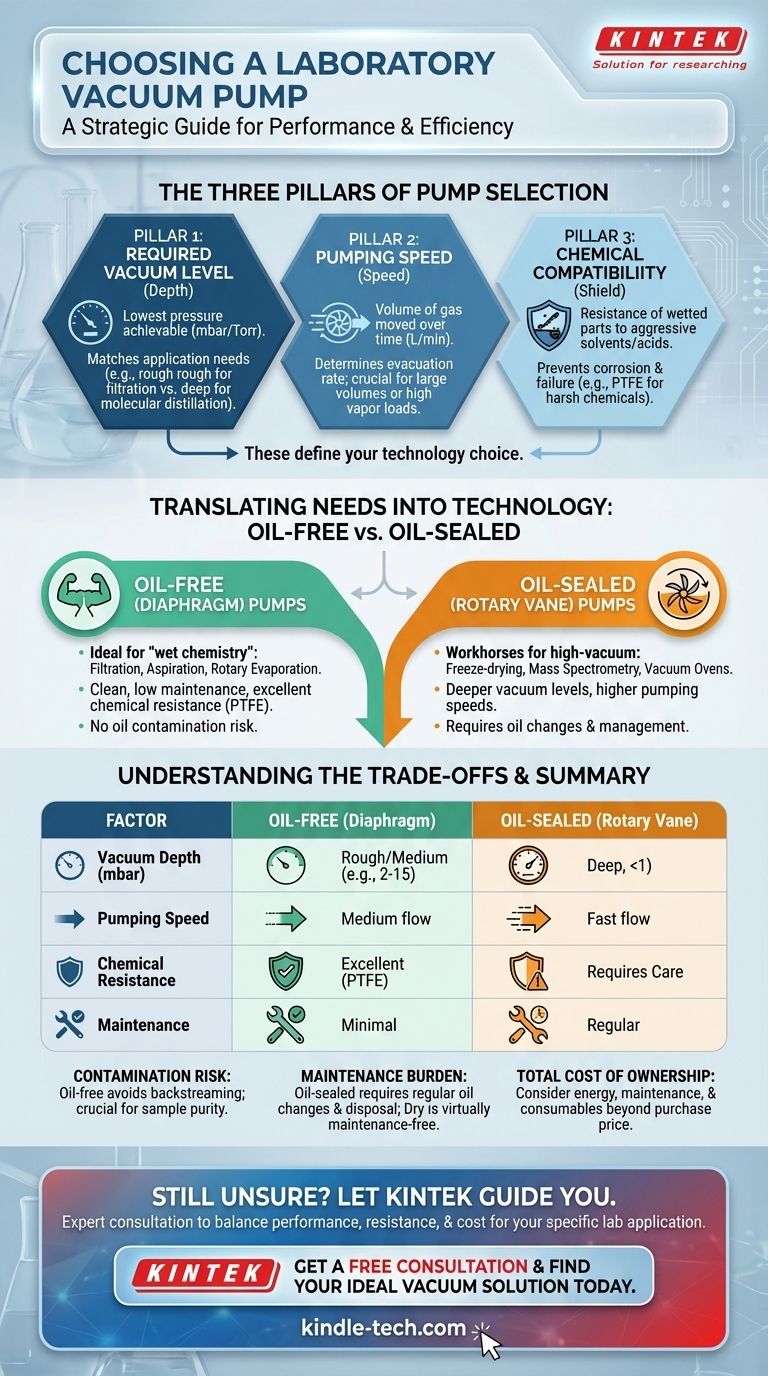

The Three Pillars of Pump Selection

Your choice will be built upon three foundational requirements. Getting these right will narrow your options from dozens to a select few.

Pillar 1: Required Vacuum Level (The "Depth")

The vacuum level, or ultimate pressure, is the lowest pressure the pump can achieve. This is the single most important technical specification and is directly tied to your application.

Different laboratory processes require vastly different vacuum levels. A simple filtration only needs a rough vacuum to pull liquid through a filter, while molecular distillation requires a deep vacuum to lower the boiling point of sensitive compounds.

This value is measured in units like millibar (mbar) or Torr. A lower number signifies a deeper (better) vacuum.

Pillar 2: Pumping Speed (The "Speed")

Pumping speed, or flow rate, measures the volume of gas the pump can move per unit of time (e.g., liters/minute). This determines how quickly the pump can evacuate your chamber or system.

While a deep ultimate vacuum is critical, a low pumping speed can create a bottleneck, especially when working with large vessels like desiccators or multi-liter reactors. You need enough speed to outpace any leaks or outgassing from your materials.

Consider both the size of your system and the nature of your process. Evaporation, for instance, generates a high volume of vapor that the pump must remove quickly to maintain the target pressure.

Pillar 3: Chemical Compatibility (The "Shield")

Many lab processes involve aggressive solvents, acids, or bases. If these vapors are drawn into the pump, they can corrode the internal components, leading to premature failure.

You must ensure the pump's wetted parts—the diaphragm, seals, and valves that come into contact with the vapor stream—are made from resistant materials. Polytetrafluoroethylene (PTFE) and related fluoropolymers are common choices for chemically resistant pumps.

Ignoring chemical compatibility is one of the most common and costly mistakes. A standard pump can be destroyed in weeks or even days by corrosive vapors it was not designed to handle.

Translating Needs into Technology: Oil vs. Oil-Free

Once you define your needs across the three pillars, your choice will likely come down to two primary technologies: oil-free diaphragm pumps or oil-sealed rotary vane pumps.

The Case for Oil-Free (Diaphragm) Pumps

These pumps generate a vacuum by flexing a diaphragm. They are exceptionally clean, require very little maintenance, and can be made highly chemically resistant.

Oil-free pumps are the standard choice for "wet chemistry" applications like filtration, aspiration, and rotary evaporation. Their vacuum level is perfectly suited for evaporating common solvents without risking sample contamination from pump oil.

The Case for Oil-Sealed (Rotary Vane) Pumps

These pumps use rotating vanes sealed by a thin film of oil to achieve much deeper vacuum levels than diaphragm pumps. They are the workhorses for high-vacuum applications.

You need a rotary vane pump for tasks like freeze-drying, mass spectrometry, or operating vacuum ovens at very low pressures. They also typically offer higher pumping speeds.

Understanding the Trade-offs

Every pump technology comes with compromises. Being aware of them is crucial for long-term success in the lab.

The Risk of Contamination

The primary drawback of an oil-sealed pump is the risk of oil backstreaming, where oil vapor migrates from the pump into your vacuum system. This can contaminate sensitive samples, rendering experiments useless.

This risk is why oil-free diaphragm pumps are heavily favored for any application where sample purity is paramount, even if an oil-sealed pump could technically do the job.

The Burden of Maintenance

Oil-sealed pumps require regular oil changes. This process involves handling used pump oil, which may be contaminated with hazardous chemicals from your experiments, creating a disposal challenge. Failure to change the oil leads to poor performance and pump failure.

Dry diaphragm pumps, by contrast, are virtually maintenance-free, often running for thousands of hours before a diaphragm replacement is needed.

The Total Cost of Ownership

Do not evaluate a pump on its purchase price alone. Consider the total cost, which includes energy consumption, maintenance time, and consumables like oil.

An inexpensive oil pump can quickly become more costly than a premium dry pump when you factor in the recurring cost of oil, filter cartridges, and the technician's time required for maintenance.

Making the Right Choice for Your Application

Use your primary application as the ultimate guide to your decision.

- If your primary focus is general filtration or aspiration: A basic, inexpensive oil-free diaphragm pump is all you need.

- If your primary focus is rotary evaporation of solvents: Choose a chemically resistant oil-free diaphragm pump with a vacuum level appropriate for your solvents (e.g., 2-10 mbar).

- If your primary focus is freeze-drying or high-vacuum science (e.g., mass spec): You will require an oil-sealed rotary vane pump, often paired with an oil mist filter and a cold trap to protect both the pump and your sample.

- If your primary focus is drying samples in a desiccator or small oven: A compact oil-free diaphragm pump offers a clean and maintenance-free solution.

By first defining your core needs for vacuum depth, speed, and chemical resistance, you can confidently select the right technology for your work.

Summary Table:

| Selection Factor | Key Question | Oil-Free (Diaphragm) Pump | Oil-Sealed (Rotary Vane) Pump |

|---|---|---|---|

| Vacuum Level | How deep a vacuum do you need? | Rough to medium vacuum (e.g., 2-15 mbar) | Deep vacuum (e.g., < 1 mbar) |

| Pumping Speed | How fast do you need to evacuate your system? | Lower to moderate flow rates | Higher flow rates |

| Chemical Compatibility | Will corrosive vapors be present? | Excellent chemical resistance (PTFE wetted parts) | Requires careful oil and filter management |

| Maintenance | How much upkeep are you willing to perform? | Virtually maintenance-free | Regular oil changes and filter replacements |

| Ideal Applications | What is your primary process? | Filtration, rotary evaporation, aspiration | Freeze-drying, mass spectrometry, high-vacuum ovens |

Still Unsure Which Vacuum Pump is Right for Your Lab?

Choosing the correct vacuum pump is critical for your experimental success and operational efficiency. The wrong choice can lead to contamination, frequent breakdowns, and costly downtime.

Let KINTEK's experts guide you. We specialize in laboratory equipment and consumables, and we understand the precise demands of research environments. We'll help you analyze your specific application—whether it's routine filtration, sensitive evaporation, or high-vacuum processes—to recommend the perfect pump that balances performance, chemical resistance, and total cost of ownership.

We provide:

- Expert Consultation: Get personalized advice based on your vacuum level, pumping speed, and chemical exposure needs.

- Reliable Equipment: Access a range of high-quality, durable oil-free and oil-sealed vacuum pumps from trusted manufacturers.

- Ongoing Support: Ensure your equipment runs smoothly with our support for maintenance and consumables.

Don't let pump selection slow down your science. Contact our technical team today for a free, no-obligation consultation and find the ideal vacuum solution for your laboratory.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the function of alumina setter plates for LATP? Protect Material Purity & Prevent Adhesion

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination

- What material is used in refractory? A Guide to High-Temperature Material Selection

- What are the overall advantages of using vacuum pumps? Achieve Unmatched Process Control & Efficiency

- What does a high pressure switch do on a furnace? A Critical Safety Gatekeeper for Your Home

- What are the advantages of using Rotary Vane Vacuum Pumps? The Versatile Workhorse for Laboratory Efficiency

- What kind of insulation is used in a furnace? A Guide to Optimizing Thermal Efficiency and Performance

- How is furnace temperature measured? A Guide to Thermocouples vs. Pyrometers