When hydraulic pressure exceeds design limits, the system enters a state of critical failure. This over-pressurization immediately targets the weakest components, causing seals to blow, hoses to burst, and fittings to leak. In more severe cases, it can cause catastrophic damage to pumps, motors, and actuators, creating significant safety hazards from high-velocity fluid jets or uncontrolled machine movement.

Excessive hydraulic pressure is more than just a risk of component failure; it is a critical sign that the system is operating inefficiently and unsafely. It wastes energy, generates damaging heat, and accelerates wear on every part of the system, leading to premature failure and significant operational risks.

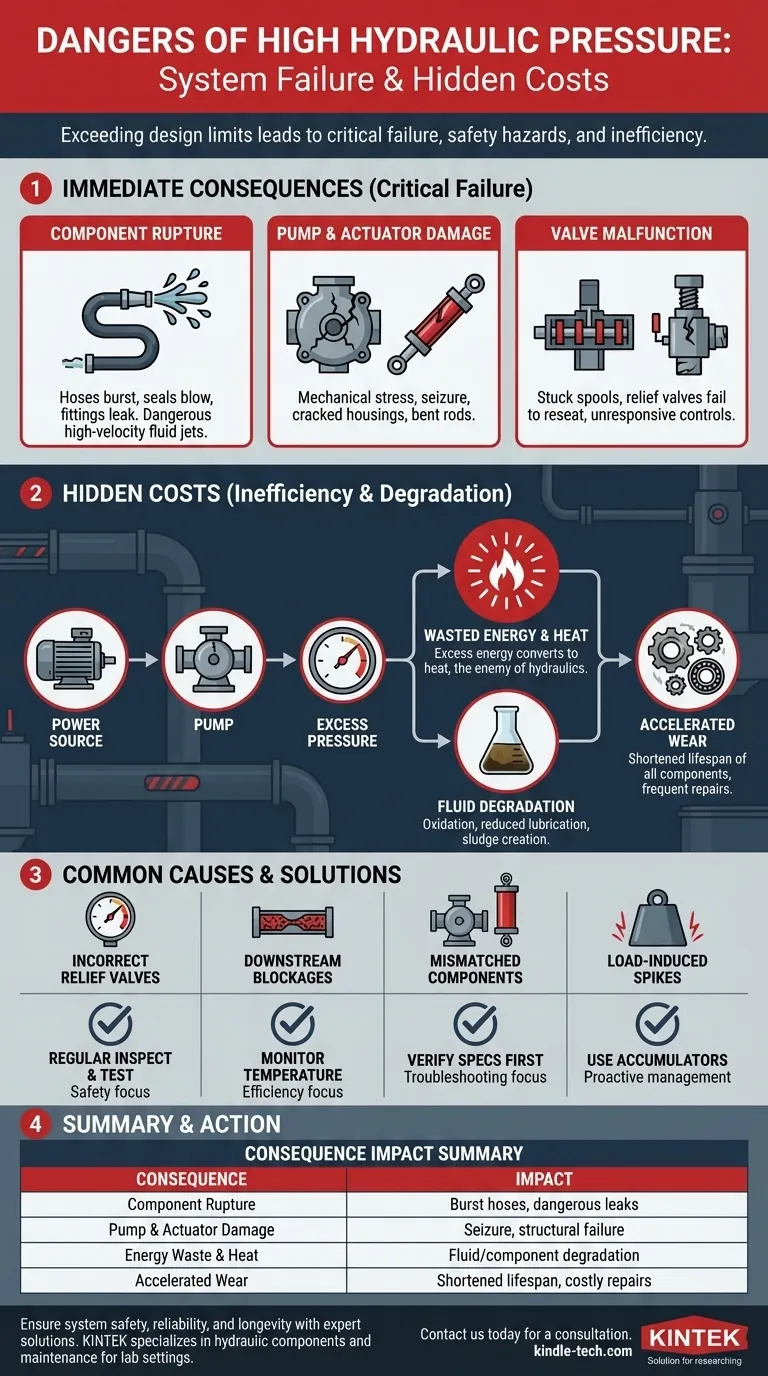

The Immediate Consequences of Over-Pressurization

High pressure places a load on the entire hydraulic circuit that it was not designed to withstand. The consequences are often immediate and destructive.

Component Rupture and Leaks

The most common failures occur at the system's points of containment. Hoses, seals, and O-rings have specific pressure ratings, and exceeding them leads to rupture. A burst hose not only disables the machine but also creates a dangerous high-pressure spray of hydraulic fluid.

Pump and Actuator Damage

Hydraulic pumps and motors are built to precise tolerances. Excessive pressure creates immense mechanical stress on their internal rotating groups, bearings, and shafts. This can lead to accelerated wear, component seizure, or even a cracked pump housing. Similarly, actuators like hydraulic cylinders can see their barrels bulge, rods bend, or internal pistons fail.

Valve Malfunction

Control valves are also susceptible. High pressure can cause spools inside directional control valves to stick, preventing the system from responding to operator commands. Pressure relief valves, the system's primary safety device, can be forced open so violently that they fail to reseat properly, or the shock can damage them internally.

The Hidden Costs: Inefficiency and System Degradation

Even if pressure isn't high enough to cause an immediate rupture, operating above the optimal level silently destroys the system and wastes energy.

Wasted Energy and Excess Heat

A hydraulic system's prime mover (an electric motor or diesel engine) provides power to the pump. If the system pressure is higher than needed to move the load, that extra energy has to go somewhere. It is converted directly into heat, which is the primary enemy of any hydraulic system.

Accelerated Fluid Degradation

Excess heat breaks down hydraulic fluid, a process known as oxidation. This changes the fluid's viscosity, reduces its ability to lubricate, and creates sludge and varnish. Degraded fluid accelerates wear on all system components and can clog fine orifices in sophisticated control valves.

Increased Mechanical Wear

Every pound of excess pressure adds a proportional amount of stress to the entire system. Bearings, shafts, gears, and cylinder mounts are all subjected to higher loads than they were designed for. This drastically shortens the operational lifespan of these expensive components, leading to more frequent and costly repairs.

Understanding the Common Causes

Excess pressure is a symptom, not the root problem. Identifying the cause is critical for a reliable fix.

Incorrectly Set Relief Valves

The pressure relief valve is the most common source of pressure issues. If it is set too high, it fails to protect the system from over-pressurization. Conversely, if a relief valve fails or sticks shut, the system has no protection at all, and pressure will spike until something breaks or the prime mover stalls.

Downstream Blockages

A blockage in a hose, a stuck valve, or a mechanically jammed cylinder can prevent fluid flow. The pump, however, continues to try and move fluid, causing pressure to rise rapidly until the relief valve opens or a component fails.

Mismatched Components

Installing a pump capable of generating higher pressure than the rest of the system's components (hoses, valves, actuators) are rated for is a frequent mistake. The system will always be at risk, as the pump can easily exceed the burst pressure of the weakest component.

Load-Induced Pressure Spikes

In dynamic applications, stopping a heavy load quickly can cause a momentary but extremely high pressure spike. This is due to the inertia of the load forcing fluid back against a closed valve, creating a "water hammer" effect that can damage components if not properly managed with accumulators or specialized valves.

Making the Right Choice for Your Goal

Effectively managing pressure is about balancing performance with reliability and safety. Your approach should be dictated by your primary objective.

- If your primary focus is safety and reliability: Regularly inspect and test your pressure relief valves to ensure they are set to the manufacturer's specified limit, not an arbitrary higher value.

- If your primary focus is operational efficiency: Monitor system temperature, as excess heat is a direct indicator of wasted energy from unnecessarily high pressure settings.

- If you are troubleshooting frequent component failures: Always start by connecting a pressure gauge to the system to verify that operating and relief pressures are within the designed specifications before replacing parts.

Proactively managing hydraulic pressure is the single most effective strategy for ensuring a system's longevity, safety, and efficiency.

Summary Table:

| Consequence | Impact |

|---|---|

| Component Rupture | Burst hoses, blown seals, dangerous fluid leaks |

| Pump & Actuator Damage | Seizure, cracked housings, bent rods from extreme stress |

| Energy Waste & Heat | Excess pressure converts to heat, degrading fluid and components |

| Accelerated Wear | Shortened lifespan for bearings, shafts, and other parts |

Is your hydraulic system operating safely and efficiently? Uncontrolled pressure can lead to dangerous failures and costly downtime. KINTEK specializes in lab equipment and consumables, including hydraulic system components and maintenance solutions for laboratory settings. Our experts can help you ensure your systems run at optimal pressure for maximum safety, reliability, and longevity. Contact us today for a consultation and protect your valuable equipment.

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Variable Speed Peristaltic Pump

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is a hydraulic hot press machine? A Guide to Force and Heat for Material Transformation

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What is the role of a hydraulic press with heating plates in copper welding tests? Analyze Stress & Thermal Cycles

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- How does a hydraulic hot press machine work? Unlock Precision in Material Bonding and Forming