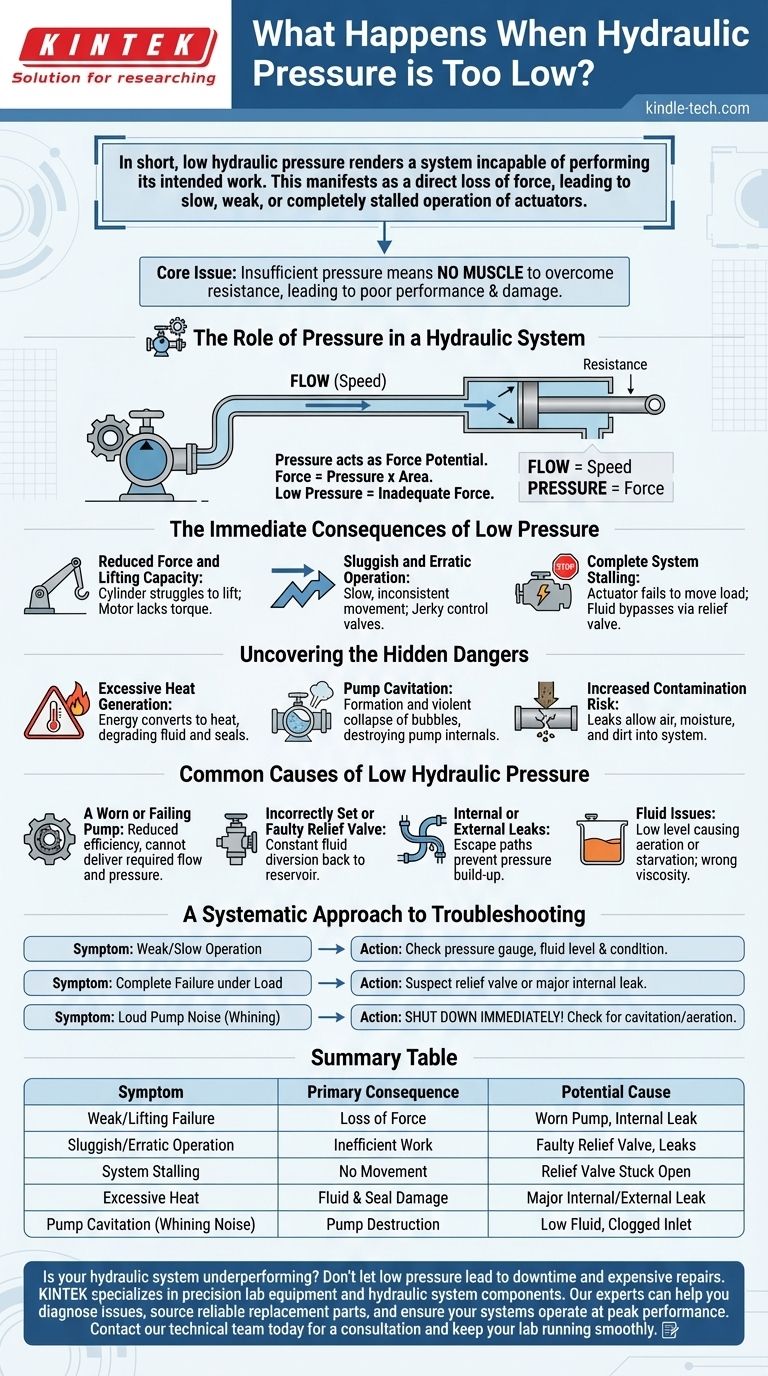

In short, low hydraulic pressure renders a system incapable of performing its intended work. This manifests as a direct loss of force, leading to slow, weak, or completely stalled operation of actuators like cylinders and motors.

The core issue is that hydraulic pressure is the direct enabler of force. When pressure is insufficient, the system lacks the fundamental "muscle" required to overcome the resistance of a load, leading not only to poor performance but also to potential long-term component damage.

The Role of Pressure in a Hydraulic System

Hydraulic systems don't create energy; they transmit it. The pump creates flow (the movement of fluid), but it is the resistance to this flow that generates pressure.

Pressure as Force Potential

Think of pressure as the potential to do work, stored within the confined fluid. This pressure acts equally in all directions, pushing on every surface it touches.

The amount of force an actuator can produce is a direct calculation: Force = Pressure x Area. If the pressure is too low, the force output will be inadequate, regardless of the actuator's size.

The Relationship Between Flow and Pressure

It's crucial to distinguish between flow and pressure. Flow determines the speed of an actuator. Pressure determines the force it can exert.

A system can have adequate flow but still fail if it cannot generate the pressure needed to move a load. This is a common point of failure.

The Immediate Consequences of Low Pressure

The symptoms of low hydraulic pressure are often obvious and directly impact machine performance.

Reduced Force and Lifting Capacity

This is the most direct consequence. A cylinder may struggle to lift a load it could previously handle, or a hydraulic motor may lack the torque to turn its shaft. The machine simply becomes weak.

Sluggish and Erratic Operation

Low pressure can cause actuators to move slowly or inconsistently. It can also prevent control valves from shifting fully and crisply, leading to jerky and unpredictable machine behavior.

Complete System Stalling

If the required pressure to move a load is higher than what the system can produce, the actuator will stall or may not move at all. The fluid will simply bypass the actuator through the path of least resistance, often a pressure relief valve.

Uncovering the Hidden Dangers

Beyond poor performance, operating with low pressure can introduce destructive, long-term problems that are much more costly to fix.

Excessive Heat Generation

If a pump is producing flow but the pressure remains low due to a significant leak or an open relief valve, the energy is not converted into useful work. Instead, it is converted directly into heat, which degrades hydraulic fluid, damages seals, and shortens component life.

Pump Cavitation

Cavitation is the formation and violent collapse of vapor bubbles within the fluid, typically caused by insufficient pressure at the pump's inlet (a starved pump). This process is extremely destructive, eroding and pitting critical internal pump surfaces, leading to premature failure.

Increased Contamination Risk

The cause of low pressure is often a leak. A leak that allows fluid to escape also provides a potential entry point for air, moisture, and dirt to enter the system, contaminating the fluid and accelerating wear on all components.

Common Causes of Low Hydraulic Pressure

Diagnosing the problem requires understanding the most common failure points in a system.

A Worn or Failing Pump

The pump is the heart of the system. As its internal components wear, its efficiency drops, and it can no longer deliver the required flow at the desired pressure. This is often a gradual decline in performance.

Incorrectly Set or Faulty Relief Valve

The pressure relief valve is the system's safety. If it is set too low or becomes stuck partially open, it will constantly divert fluid back to the reservoir, preventing the system from ever reaching its required operating pressure.

Internal or External Leaks

An external leak from a hose or fitting is obvious. An internal leak, such as fluid bypassing a worn piston seal in a cylinder or a worn seal in a directional control valve, is invisible but has the same effect: it provides an escape path for fluid, preventing pressure from building effectively.

Fluid Issues

A low fluid level in the reservoir can cause the pump to ingest air (aeration) or be starved of fluid, making pressure generation impossible. Likewise, using fluid with the wrong viscosity, especially when cold, can also impede proper operation.

A Systematic Approach to Troubleshooting

When faced with low-pressure symptoms, a logical diagnostic process is essential.

- If your primary symptom is weak or slow operation: Immediately check the system pressure gauge during operation and verify the fluid level and condition in the reservoir.

- If the system fails completely under load: Suspect that the pressure relief valve is either set too low or is stuck open, or that there is a major internal leak in a primary component.

- If you hear a loud whining or knocking noise from the pump: Shut down the system immediately to prevent catastrophic failure. This is a classic sign of pump cavitation or severe aeration.

Ultimately, maintaining correct hydraulic pressure is fundamental to a system's performance, efficiency, and longevity.

Summary Table:

| Symptom | Primary Consequence | Potential Cause |

|---|---|---|

| Weak/Lifting Failure | Loss of Force | Worn Pump, Internal Leak |

| Sluggish/Erratic Operation | Inefficient Work | Faulty Relief Valve, Leaks |

| System Stalling | No Movement | Relief Valve Stuck Open |

| Excessive Heat | Fluid & Seal Damage | Major Internal/External Leak |

| Pump Cavitation (Whining Noise) | Pump Destruction | Low Fluid, Clogged Inlet |

Is your hydraulic system underperforming? Don't let low pressure lead to downtime and expensive repairs. KINTEK specializes in precision lab equipment and hydraulic system components. Our experts can help you diagnose issues, source reliable replacement parts, and ensure your systems operate at peak performance.

Contact our technical team today for a consultation and keep your lab running smoothly.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples