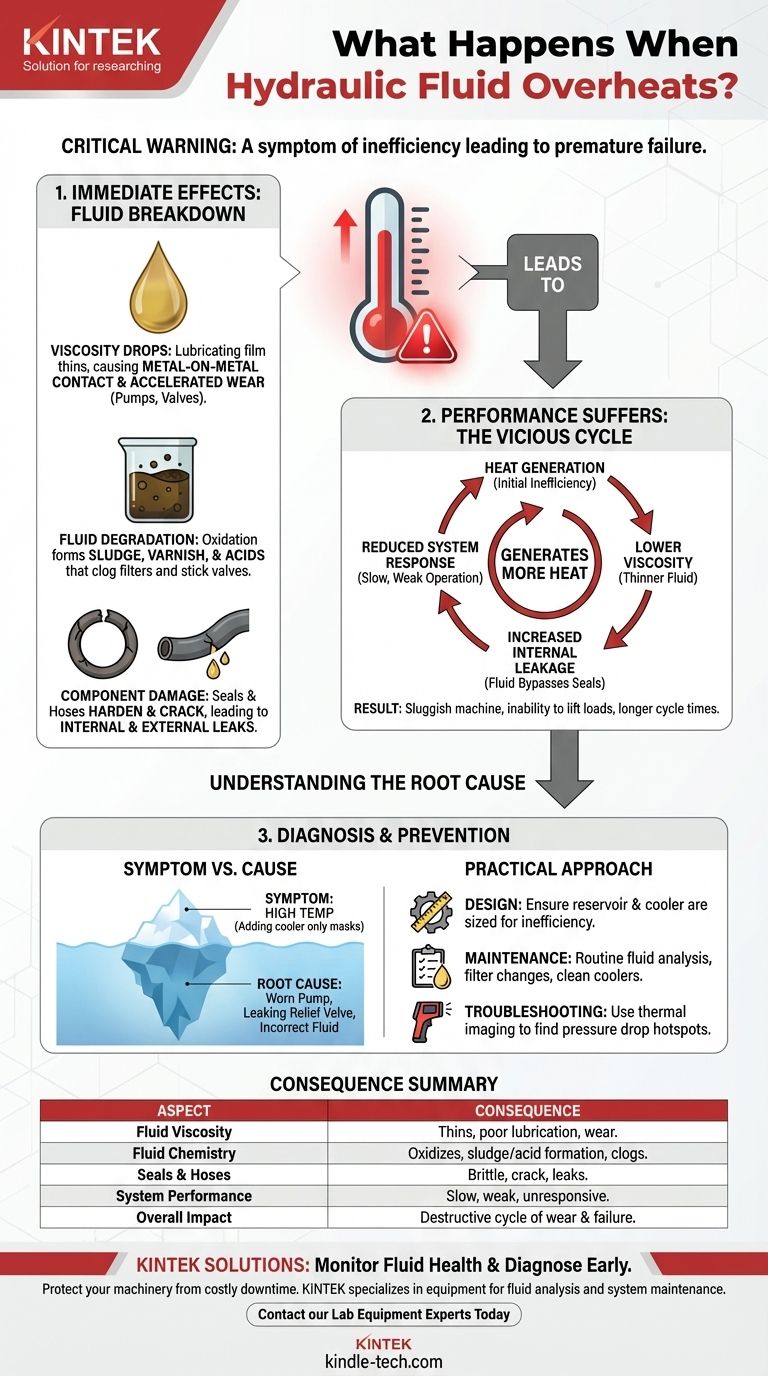

When hydraulic fluid overheats, it is a critical warning sign that your system is operating inefficiently and on a path toward premature failure. The immediate effect is a dangerous drop in the fluid's viscosity (its thickness), which compromises its ability to lubricate parts, transfer power effectively, and seal internal clearances. This triggers a cascade of chemical breakdown and physical damage to core components.

Excessive heat in a hydraulic system is not the root problem; it is a critical symptom of inefficiency. Addressing heat requires diagnosing the underlying cause—be it poor design, component wear, or incorrect fluid—to prevent a cascading cycle of damage and performance loss.

The Immediate Effects of Excessive Heat

When a hydraulic system's temperature exceeds its optimal operating range (typically above 180°F or 82°C), the fluid itself begins to change in ways that are detrimental to the entire system.

The Breakdown of Viscosity

Viscosity is the most important property of hydraulic fluid. It represents the fluid's resistance to flow and is what allows it to create a load-bearing film between moving parts.

When the fluid gets too hot, it thins out, and this lubricating film becomes weak or breaks down entirely. This leads to metal-on-metal contact in pumps, motors, and valves, causing accelerated wear.

Accelerated Fluid Degradation

Heat is a catalyst for oxidation, the chemical reaction between the fluid and oxygen. This process is often compared to "cooking" the oil.

As the fluid oxidizes, it forms sludge, varnish, and acidic byproducts. These contaminants clog filters, coat internal surfaces, cause valves to stick, and reduce the overall service life of the fluid, necessitating more frequent and costly changes.

Damage to Physical Components

Hydraulic systems rely on elastomeric seals and hoses to contain high-pressure fluid. Excessive heat causes these materials to harden and become brittle.

This loss of flexibility leads to cracks and fractures, resulting in both internal and external leaks. An external leak is a safety and environmental hazard, while an internal leak reduces system efficiency.

Why Performance Suffers in an Overheated System

The physical and chemical changes in the fluid translate directly into observable performance issues. An operator will notice the machine becoming sluggish, weak, and unpredictable.

Increased Internal Leakage

As the fluid's viscosity drops, it can more easily bypass the internal seals within components like cylinders, pumps, and motors.

This internal leakage means a portion of the fluid flow is lost and does no useful work. It simply cycles back to the reservoir, generating even more heat in the process.

Reduced System Response

Because of internal leakage, the system's actuators (cylinders and motors) receive less flow than the pump is providing.

The direct result is slower and less responsive operation. The machine may feel weak, unable to lift its rated load, or take longer to complete a cycle.

The Vicious Cycle of Heat Generation

Overheating creates a destructive feedback loop. The initial cause of heat (an inefficiency) warms the fluid, which lowers its viscosity.

This lower viscosity increases internal leakage, which is itself a major source of inefficiency. This new inefficiency generates even more heat, further reducing viscosity and accelerating the cycle of wear and performance degradation.

Understanding the Trade-offs and Root Causes

Simply observing that a system is hot is insufficient. A proper diagnosis requires understanding that heat is always the byproduct of energy that is not being used for work.

Symptom vs. Cause: The Cooler Fallacy

A common mistake is to treat an overheating problem by simply installing a larger heat exchanger (cooler). While this may lower the temperature, it only masks the symptom.

The underlying inefficiency—such as a worn-out pump or a misconfigured valve—is still present, wasting energy and costing money in fuel or electricity. The correct approach is to identify and fix the source of the heat.

The Role of System Pressure

Heat is generated any time fluid flows from an area of high pressure to an area of low pressure without performing useful work.

The most common culprit is a pressure relief valve. If a relief valve is set too low, is leaking, or is constantly open, it is dumping high-pressure oil directly to the reservoir, converting hydraulic energy into immense heat.

The Importance of Fluid Selection

Not all hydraulic fluids are created equal. A fluid's Viscosity Index (VI) measures its ability to resist viscosity changes with temperature.

A fluid with a high VI will maintain a more stable viscosity across a wide temperature range, offering better protection in systems prone to overheating. Using a low-VI fluid in a demanding application can initiate the overheating cycle.

A Practical Approach to Managing Hydraulic Temperature

Your strategy for managing heat should be based on your specific role, whether in design, maintenance, or troubleshooting.

- If your primary focus is system design and prevention: Ensure the reservoir and heat exchanger are adequately sized for the system's power output and expected inefficiencies.

- If your primary focus is maintenance and longevity: Implement a routine schedule to check fluid levels, clean cooler fins, replace filters, and perform fluid analysis to detect early signs of oxidation and thermal breakdown.

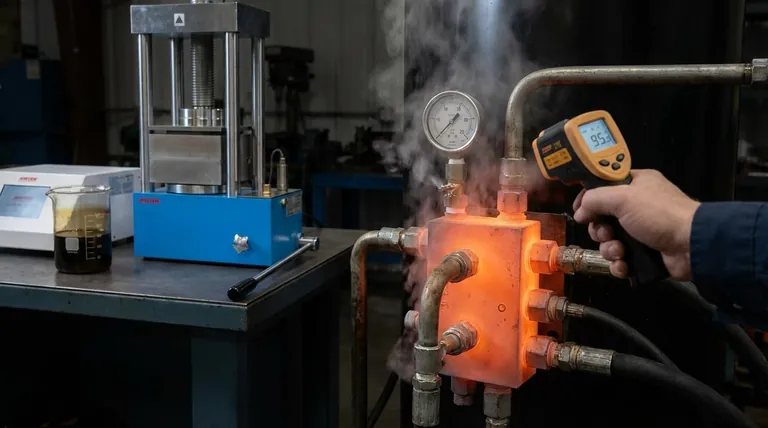

- If your primary focus is troubleshooting a hot system: Use an infrared temperature gun to scan components and find hotspots, which are direct indicators of where pressure is being dropped inefficiently.

Ultimately, managing hydraulic temperature is about managing system efficiency.

Summary Table:

| Aspect | Consequence of Overheating |

|---|---|

| Fluid Viscosity | Thins out, leading to poor lubrication and metal-on-metal contact. |

| Fluid Chemistry | Oxidizes, forming sludge, varnish, and acids that clog the system. |

| Seals & Hoses | Become brittle and crack, causing internal and external leaks. |

| System Performance | Increased internal leakage results in slow, weak, and unresponsive operation. |

| Overall Impact | Triggers a destructive cycle of wear, inefficiency, and premature failure. |

Is your hydraulic system running hot and inefficient? Don't let overheating lead to costly downtime and component failure. KINTEK specializes in the precise equipment and consumables needed for fluid analysis and system maintenance. Our solutions help you monitor fluid health and diagnose problems early, protecting your valuable machinery.

Contact our lab equipment experts today to discuss how we can support your hydraulic system's performance and longevity.

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What mechanism would cause hydraulic failure? Prevent System Breakdown with Proactive Fluid Care

- What is the function of a laboratory hydraulic press in the preparation of bulk tungsten? Achieve High Density Solids

- How pressed powder pellets are prepared? Master the Foundation for Reliable Analytical Data

- What role does a laboratory hydraulic press play in assembling solid-state fluoride ion battery test units? Key Benefits

- Why is a laboratory hydraulic press required for SOFC green bodies? Enhance Density & Performance with Precision

- What is the ratio of KBr and sample in IR? Achieve Perfect Sample Concentration for Clear IR Spectra

- What is the error range for XRF? Master Your Analytical Accuracy and Precision

- How does a laboratory hydraulic press assist in the formation of LZP solid-state electrolyte ceramic pellets?