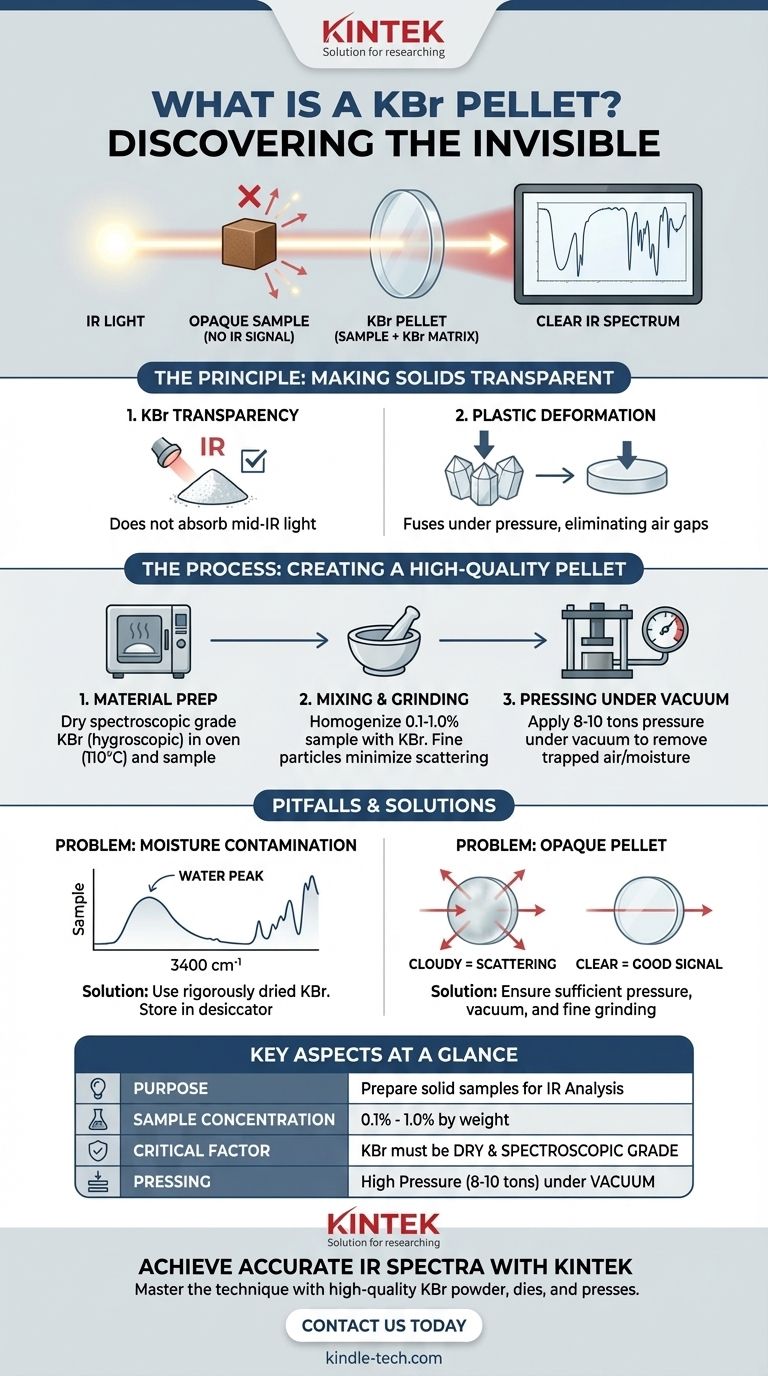

A KBr pellet is a standardized method for preparing solid samples for analysis via infrared (IR) spectroscopy. It involves finely grinding a small amount of the sample with high-purity potassium bromide (KBr) powder and compressing the mixture under high pressure to form a small, transparent disc. This disc can then be placed directly into the path of an IR spectrometer's beam.

The core challenge in analyzing solid materials with IR spectroscopy is that most are opaque to infrared light. The KBr pellet technique solves this by dispersing the sample particles within a matrix (KBr) that is transparent to IR light, allowing for a clean measurement of the sample's unique spectral fingerprint.

The Principle: Making Solids Transparent to IR Light

Infrared spectroscopy works by passing IR light through a sample and measuring which frequencies are absorbed. For this to work, the sample must be at least partially transparent. The KBr method creates this necessary transparency for solid powders.

Why Potassium Bromide is Used

Potassium bromide (KBr) is an alkali halide salt with two critical properties. First, it is transparent across the mid-infrared range, meaning it does not absorb IR light in the region where most organic and inorganic compounds show their characteristic peaks.

Second, under immense pressure, KBr powder undergoes plastic deformation. This causes the individual salt crystals to fuse together, forming a solid, glass-like disc that eliminates the air gaps between particles that would otherwise scatter the IR light beam.

The Importance of Dilution

Samples are typically mixed with KBr at a very low concentration, usually around 0.1% to 1.0% by weight. This dilution is essential.

If the sample is too concentrated, it will absorb too much light, resulting in "flat-topped" or saturated peaks in the spectrum, making the data useless for quantitative analysis. Dispersing the sample evenly throughout the KBr matrix ensures the absorption is proportional to its concentration.

The Process of Creating a High-Quality Pellet

The quality of the final spectrum is entirely dependent on the quality of the pellet. This requires careful attention to detail at each step.

Step 1: Material Preparation

The process begins with preparing the materials. The KBr powder must be of spectroscopic grade purity and, critically, must be completely dry. KBr is hygroscopic, meaning it readily absorbs moisture from the air.

To remove moisture, the powder is typically dried in an oven at around 110°C for several hours and stored in a desiccator. The sample itself should also be dry and finely ground.

Step 2: Mixing and Grinding

A small, precisely weighed amount of sample (e.g., 1-2 mg) is combined with a larger amount of dried KBr (e.g., 200-300 mg). This mixture is then ground together, typically with an agate mortar and pestle.

The goal is to thoroughly homogenize the mixture and reduce the particle size to minimize light scattering. Inadequate mixing is a common source of poor-quality spectra.

Step 3: Pressing Under Vacuum

The ground powder is transferred into a specialized pellet die. The die is placed in a hydraulic press, and pressure (typically 8-10 tons) is applied.

Crucially, a vacuum is pulled on the die during pressing. This removes trapped air and any residual moisture, which are primary causes of cloudy, opaque pellets that scatter light and produce noisy, unusable spectra.

Understanding the Trade-offs and Pitfalls

While the KBr pellet method is a powerful standard, it is not without its challenges. Understanding these is key to troubleshooting and obtaining reliable data.

The Problem of Moisture Contamination

Because KBr is so hygroscopic, water contamination is the most frequent issue. Any absorbed water will appear in the IR spectrum as a very broad absorption band around 3400 cm⁻¹ (O-H stretch) and a weaker one around 1640 cm⁻¹ (H-O-H bend).

These water peaks can obscure important sample peaks in the same regions, making interpretation difficult or impossible. Using rigorously dried KBr is the only solution.

Pellet Quality: Transparent vs. Opaque

A high-quality pellet is perfectly clear and transparent. A cloudy or opaque pellet indicates a problem, usually insufficient pressure, trapped air from an inadequate vacuum, or particles that were not ground finely enough.

An opaque pellet will cause significant light scattering, leading to a sloping baseline and a poor signal-to-noise ratio in the final spectrum.

The Background Measurement is Non-Negotiable

No KBr pellet is perfect. It will always have some minor absorption or scattering effects. To correct for this, a background spectrum must be run using a pellet made from pure KBr (from the same batch) or simply with an empty pellet holder.

The spectrometer software then subtracts this background from the sample spectrum, removing any interfering signals from the KBr matrix, atmospheric CO₂, or water vapor.

Making the Right Choice for Your Goal

The KBr pellet technique remains a gold standard for its high-quality results when performed correctly. Tailor your focus based on your analytical objective.

- If your primary focus is quantitative analysis: Be meticulous about weighing your sample and KBr, ensure homogenous mixing, and press pellets with consistent thickness to ensure reproducible results.

- If your primary focus is qualitative identification: Prioritize eliminating moisture and achieving a transparent pellet to obtain a clean, recognizable spectral fingerprint free from interfering peaks.

- If you are troubleshooting poor results: Check for a sloping baseline (improve grinding and vacuum), broad water peaks (re-dry your KBr), or saturated signals (reduce your sample-to-KBr ratio).

By mastering this technique, you transform a simple disc of salt into a powerful window for observing the molecular world.

Summary Table:

| Key Aspect | Description |

|---|---|

| Purpose | Prepare solid samples for analysis via Infrared (IR) Spectroscopy. |

| Principle | Disperses sample in a KBr matrix transparent to IR light. |

| Sample Concentration | Typically 0.1% to 1.0% by weight. |

| Critical Factor | KBr must be spectroscopic grade and completely dry (hygroscopic). |

| Pressing Conditions | High pressure (8-10 tons) under vacuum to remove air/moisture. |

| Ideal Pellet | Clear and transparent; cloudy pellets indicate issues. |

Achieve Clear, Accurate IR Spectra with KINTEK

Mastering the KBr pellet technique is essential for reliable solid sample analysis. KINTEK specializes in supplying the high-quality laboratory equipment and consumables you need for success, including spectroscopic grade KBr powder, durable pellet dies, and reliable hydraulic presses.

Let us help you eliminate common pitfalls like moisture contamination and poor pellet quality. Our products are designed to support researchers and lab technicians in obtaining the clean, interpretable data required for both qualitative identification and quantitative analysis.

Contact us today via our [#ContactForm] to discuss your specific lab needs and discover how KINTEK's solutions can enhance your IR spectroscopy workflow.

Visual Guide

Related Products

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Ring Press Mold for Lab Applications

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

People Also Ask

- What is the highest pressure in a hydraulic press? Unlock the True Power of Force Multiplication

- What are 3 important maintenance procedures for hydraulic systems? Prevent Costly Failures & Downtime

- What products are made with a hydraulic press? From Car Parts to Cosmetics, Shaping Modern Manufacturing

- Why is my hydraulic press leaking? Diagnose and Fix Common Seal & Cylinder Issues

- What is rolling pressure? Master the Key to Material Deformation and Quality Control

- What is a hydraulic jack? The Simple Physics of Lifting Heavy Loads

- How do PTFE holders or laboratory presses contribute to electrode prep? Ensure Precision in Corrosion Testing

- What are the advantages of metal pressing? Unlock High-Speed, Low-Cost Mass Production