At its core, a muffle furnace is an insulated, high-temperature oven used for heat treatment processes that can be performed in the presence of ambient air. Its defining characteristic is its operational simplicity and the fact that it does not use a controlled or modified atmosphere. While versatile for many general heating tasks, this direct exposure to air makes it unsuitable for processes where surface oxidation or contamination must be avoided.

The critical distinction is this: a muffle furnace is for heating materials in air. If your process requires a pristine, oxygen-free environment to prevent oxidation, you need a specialized atmosphere furnace, such as a vacuum furnace.

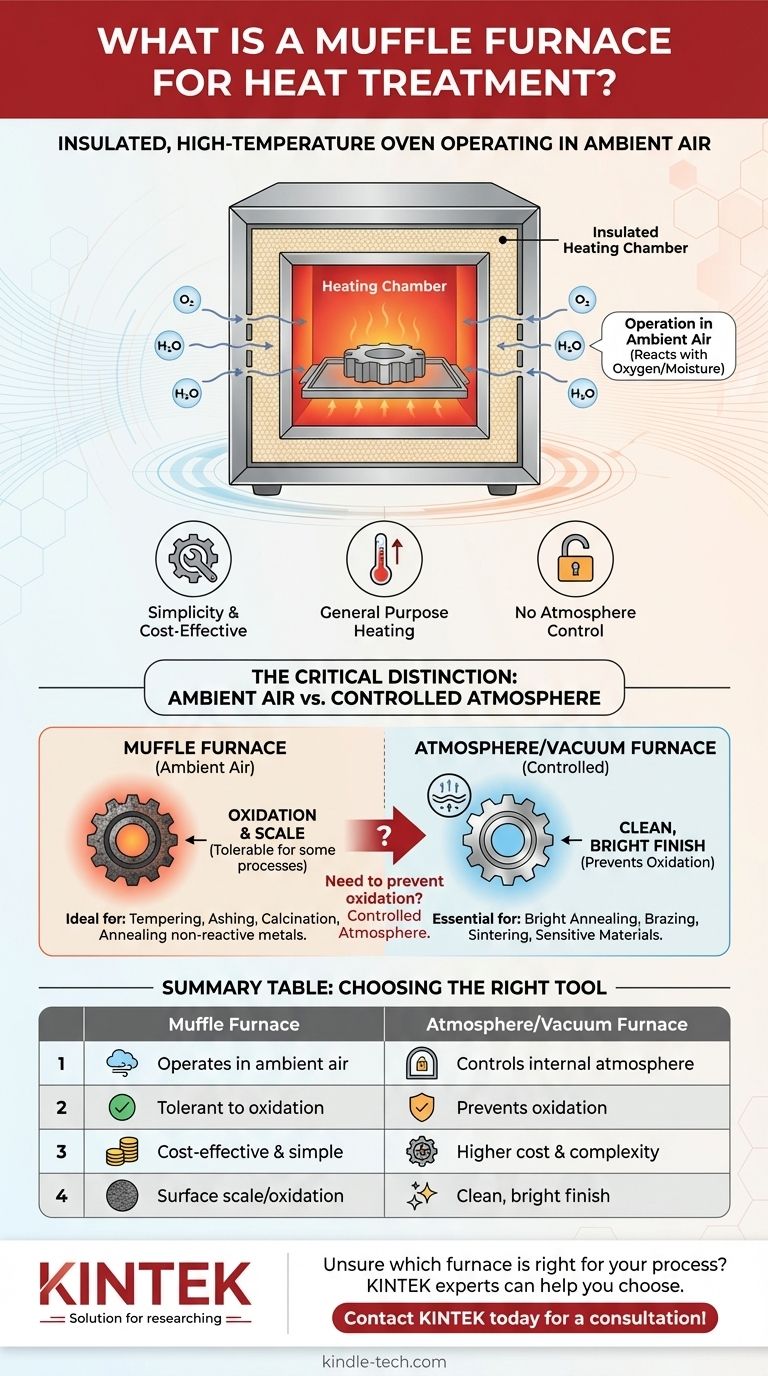

What Defines a Muffle Furnace?

A muffle furnace is one of the most common pieces of high-temperature equipment found in laboratories and workshops. Its design and function are straightforward, revolving around a few key principles.

The Insulated Heating Chamber

The term "muffle" historically referred to a ceramic box that shielded a part from the direct flames of a fuel-fired furnace. In modern electric furnaces, the term broadly applies to the entire insulated heating chamber that isolates the material and contains the heat.

This chamber is typically lined with high-performance ceramic insulation and contains heating elements that radiate heat to the workpiece inside.

Operation in Ambient Air

The most important functional detail of a standard muffle furnace is that it operates in normal air. It does not have the seals, pumps, or gas-handling systems required to create a vacuum or introduce a protective gas.

When a metal is heated in a muffle furnace, it is reacting with the oxygen and moisture present in the air.

Simplicity and Cost-Effectiveness

Because they lack complex atmospheric controls, muffle furnaces are generally more cost-effective, easier to use, and simpler to maintain than their vacuum or controlled-atmosphere counterparts. They are ideal for straightforward heating applications.

When is a Muffle Furnace the Right Choice?

A muffle furnace is the correct tool when the heat treatment process is either tolerant of or benefits from an oxygen-rich environment.

Processes Tolerant to Oxidation

Many heat treatment processes do not require a pristine surface finish. For tasks like tempering, stress relieving, or annealing non-reactive metals, the slight oxidation that occurs is often acceptable and can be removed later if necessary.

General Purpose Heating and Testing

These furnaces are workhorses for a variety of lab and research tasks. This includes ash content determination, materials testing, drying, and pre-heating components for subsequent operations.

Air Calcination

Calcination is the process of heating a material to a high temperature to cause thermal decomposition or phase transition. When done in a muffle furnace, it is called air calcination, and it leverages the presence of oxygen for the desired chemical reaction.

Understanding the Trade-offs: Muffle vs. Atmosphere Furnaces

Choosing the wrong furnace is a common and costly error in heat treatment. The decision almost always comes down to one factor: the need for atmospheric control.

The Critical Role of Atmosphere

For many advanced applications, controlling the atmosphere is non-negotiable. It is the only way to prevent oxidation (scaling), decarburization (loss of carbon from steel), and other surface contamination. A clean, controlled environment ensures superior mechanical properties and a bright, untarnished finish.

The Problem: Oxidation

When you heat most common metals (like steel) in a muffle furnace, the hot surface reacts with oxygen to form a dark, flaky layer of oxide scale. This scale must be cleaned off, can ruin surface finish, and in some cases, can affect the part's final dimensions.

The Alternative: Vacuum and Atmosphere Furnaces

A vacuum furnace represents the opposite approach. By pumping out nearly all the air, it creates an ultra-clean environment that eliminates oxidation entirely. This allows for processes like bright annealing, vacuum brazing, and high-purity sintering.

These advanced furnaces can perform almost any heat treatment process, delivering components with predictable, high-quality results that are impossible to achieve in a muffle furnace.

Making the Right Choice for Your Process

Your choice of furnace must be dictated by the required outcome of the material you are treating.

- If your primary focus is cost-effective, simple heating where surface oxidation is acceptable: A muffle furnace is the correct and most efficient tool for the job.

- If your primary focus is a clean surface finish, preventing oxidation, or performing advanced processes like brazing or carburizing: You must use an atmosphere-controlled furnace, such as a vacuum furnace.

Ultimately, selecting the right furnace is about aligning the tool's capability with your specific engineering goal.

Summary Table:

| Muffle Furnace | Atmosphere/Vacuum Furnace |

|---|---|

| Operates in ambient air | Controls the internal atmosphere |

| Ideal for processes tolerant to oxidation (e.g., tempering, ashing) | Essential for preventing oxidation (e.g., bright annealing, brazing) |

| Cost-effective and simple to operate | More complex and higher initial cost |

| Can cause surface scale/oxidation | Delivers clean, bright, high-quality finishes |

Unsure which furnace is right for your heat treatment process?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you choose the perfect furnace—whether a cost-effective muffle furnace for general heating or a high-precision atmosphere furnace for oxidation-sensitive applications—to ensure your materials meet exact specifications.

Contact KINTEK today for a personalized consultation and unlock the full potential of your lab's thermal processing!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the precautions of muffle furnace? Essential Safety Protocols for Your Lab

- What is a muffle furnace used for in microbiology? Essential for Depyrogenation and Ashing

- What is the operating temperature of the muffle furnace? Find Your Ideal Range for Lab Success

- What is the difference between muffle furnace and induction furnace? Choosing the Right Heat Source for Your Lab

- What is the application of a muffle furnace? Achieve Contamination-Free High-Temperature Processing