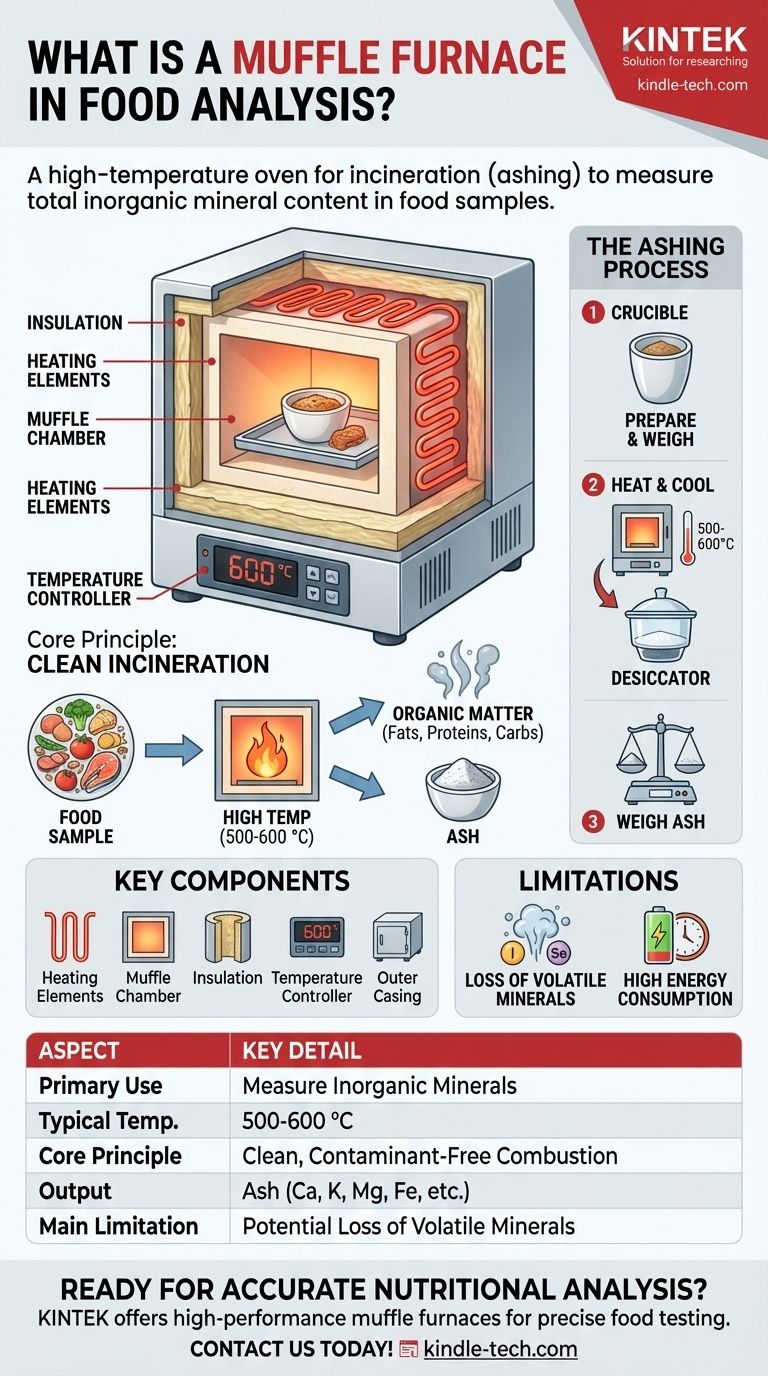

In food analysis, a muffle furnace is a high-temperature laboratory oven used for a process called incineration or "ashing." Its primary function is to completely burn away all the organic matter in a food sample—such as fats, proteins, and carbohydrates—to precisely measure the remaining inorganic mineral content. This resulting "ash" is a critical indicator of a food's nutritional composition.

The defining feature of a muffle furnace is its design, which isolates the sample in a chamber (the "muffle"), separating it from the byproducts of the heat source. This ensures that the final measurement reflects only the food's intrinsic mineral content, providing a clean and accurate basis for analysis.

The Core Principle: Clean Incineration

A muffle furnace is not just any oven. Its specific design is engineered химика for one primary purpose in food science: to determine total mineral content through complete, uncontaminated combustion.

Separating the Sample from Contamination

The term "muffle" refers to the insulated, enclosed inner chamber where the sample is heated. This chamber acts as a barrier, separating the food sample from the actual heating elements and any potential contaminants they might produce.

In older fuel-fired furnaces, this was critical to prevent soot and combustion gases from mixing with the sample. In modern electric furnaces, it ensures radiant heat is applied uniformly without direct contact with the electrical components.

Achieving Complete Combustion

Muffle furnaces operate at extremely high temperatures, typically between 500 and 600 °C (932-1112 °F) for food ashing. This intense heat causes all organic compounds to oxidize and turn into gases (like carbon dioxide and water vapor), which are vented away.

The process continues until only the non-combustible, inorganic components are left behind.

What "Ash" Represents in Food

The small amount of white or grey powder инфекция remaining after the process is complete is called ash. This ash is the total sum of the minerals present in the original food sample.

This measurement is a key parameter in nutritional analysis, representing a food's content of essential minerals like calcium, potassium, magnesium, and iron.

How a Modern Muffle Furnace Works

The reliability of a muffle furnace comes from the precise interaction of several key components, all working to maintain a stable, high-temperature environment.

Key Components

- Heating Elements: Modern furnaces use high-resistance electric coils, often made of iron-chromium-aluminum alloys, that can rapidly generate and sustain high temperatures.

- The Muffle Chamber: This is the workhorse of the furnace, made from high-density refractory ceramic материаль to withstand extreme heat and thermal shock.

- Insulation: Layers of ceramic fiber insulation surround the muffle, minimizing heat loss and making the furnace energy-efficient.

- Temperature Controller & Thermocouple: A thermocouple acts as a temperature sensor inside the chamber. It sends feedback to a digital controller, which adjusts power to the heating elements to maintain a precise, pre-set temperature.

- Outer Casing: A durable steel or aluminum shell protects the internal components and provides structural integrity.

The Ashing Process

A typical workflow involves placing a pre-weighed food sample into a ceramic or porcelain crucible. This crucible is then placed inside the cool furnace, which is programmed to heat to a specific temperature for several hours until combustion is complete. Finally, a crucible is carefully removed and cooled in a desiccator before the remaining ash is weighed.

Understanding the Trade-offs and Limitations

While essential, a muffle furnace is not a perfect tool. Understanding its limitations is crucial for accurate interpretation of results.

Loss of Volatile Minerals

The primary limitation is that the extremely high temperatures can cause some volatile minerals to be lost. Elements like chlorine, bromine, iodine, mercury, and even some selenium can turn to vapor and escape along with the organic matter.

Because of this, the "total ash" वैल्यू is an excellent approximation but may slightly underestimate the true total mineral content.

Time and Energy Consumption

Heating a furnace to 600°C and holding that temperature for hours is an energy-intensive process. The entire cycle, including the crucial cooling-down period, can take a significant amount of time, making it a bottleneck in high-throughput labs.

Safety and Handling

Operating a muffle furnace requires strict safety protocols. The exterior can become very hot, and the interior temperatures मौसम an immediate and severe burn risk. Heat-resistant gloves and long tongs are mandatory for loading or unloading samples.

Making the Right Choice for Your Goal

The data from a muffle furnace serves different purposes depending on your analytical objective.

- If your primary focus is nutritional labeling: Use the furnace to determine the total ash content, which is a required value for many nutrition facts panels and a standard proxy for total mineral content.

- If your primary focus is quality control: Use the ashing proceso to verify the consistency of mineral content in raw ingredients or finished products, ensuring they meet formulation specifications.

- If your primary focus is specific mineral analysis: Recognize that ashing in a muffle furnace is the first step. The resulting ash is then dissolved and analyzed using more advanced instruments (like Atomic Absorption Spectroscopy or ICP-MS) to quantify individual minerals.

Ultimately, the muffle furnace provides a foundational data point in food science, offering a clear window into the inorganic world hidden within organic matter.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Use | Incineration (ashing) to measure inorganic mineral content in food samples. |

| Typical Temperature Range | 500°C to 600°C (932°F to 1112°F). |

| Core Principle | Isolates the sample in a chamber for clean, contaminant-free combustion. |

| Output | Ash, representing the total sum of minerals like calcium, potassium, and iron. |

| Main Limitation | Potential loss of volatile minerals (e.g., iodine, selenium) at high temperatures. |

Ready to ensure accurate nutritional analysis in your lab? A reliable muffle furnace is the cornerstone of precise food testing. KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for the exacting needs of food science laboratories. Contact us today to find the perfect solution for your ashing and quality control workflows.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the objective of a muffle furnace? Achieve Pure, High-Temperature Processing

- Why is the metal melting temperature important? The Key to Manufacturing & Performance

- What temperature is needed for metal casting? Achieve Perfect Casts with the Right Superheat

- How does quenching work chemistry? Mastering the Atomic Race for Harder Steel

- What is an example of quenching? Achieve Optimal Hardness with Precise Cooling