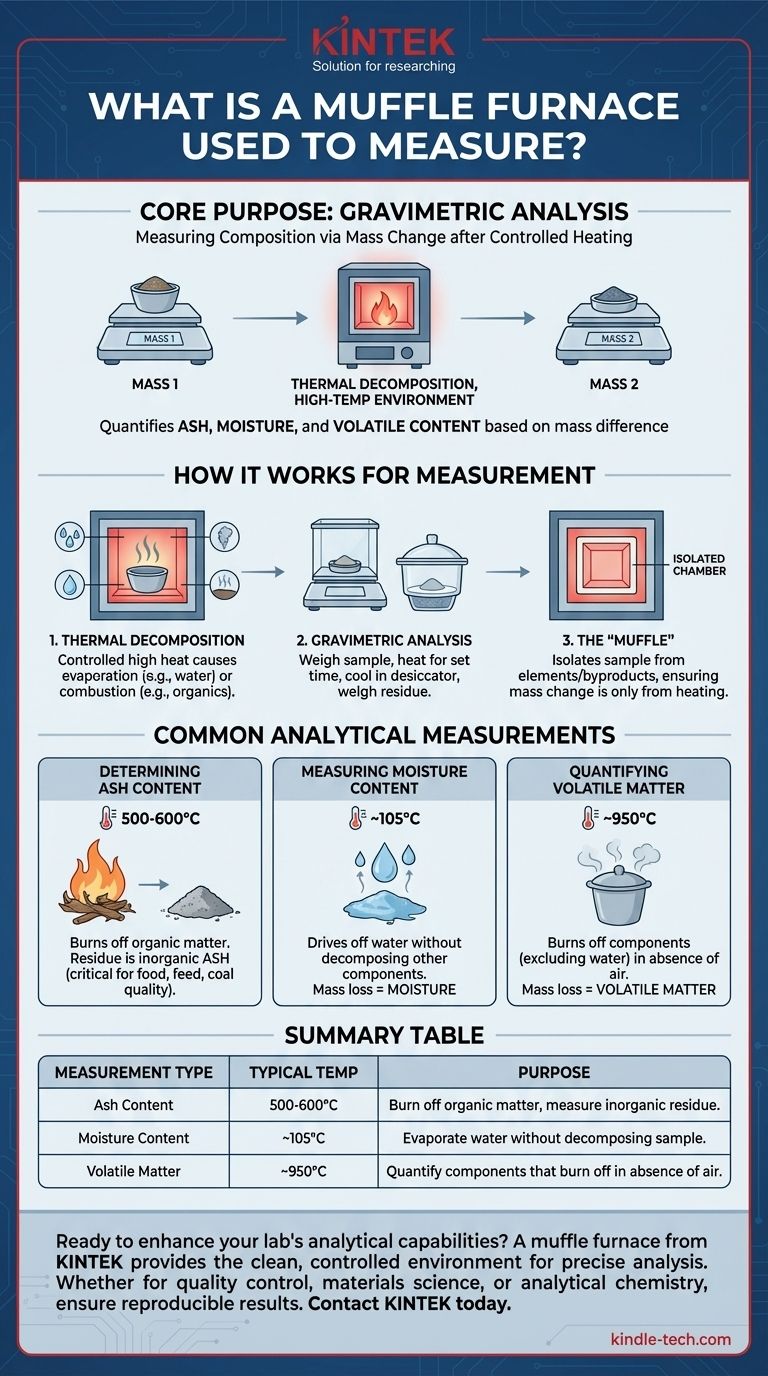

At its core, a muffle furnace is used to measure the ash, moisture, and volatile content of a sample. It accomplishes this not by measuring directly, but by creating a high-temperature, controlled environment that causes physical and chemical changes in a material, which are then quantified, typically by weighing the sample before and after heating.

A muffle furnace is not a measurement instrument in itself, but rather a sample preparation chamber. Its primary function is to enable gravimetric analysis—measuring a material's composition based on changes in its mass after controlled heating.

How a Muffle Furnace Works for Measurement

The Principle: Thermal Decomposition

A muffle furnace subjects a material to precisely controlled high temperatures. This heat causes different components within the sample to either evaporate (like water) or combust and burn away (like organic matter).

By controlling the temperature and duration, you can selectively remove specific components from the sample.

The Measurement: Analysis by Mass Difference

The actual measurement is performed with a high-precision balance, not the furnace. The process, known as gravimetric analysis, follows a simple sequence:

- A sample is weighed accurately.

- It is placed in the furnace and heated to a specific temperature for a set time.

- The sample is cooled in a desiccator (to prevent reabsorption of atmospheric moisture) and weighed again.

The difference in mass before and after heating allows you to calculate the percentage of the component that was burned off or evaporated.

The Key Component: The "Muffle"

The defining feature of this furnace is its internal chamber, or muffle. This heat-resistant box isolates the sample from the direct heating elements and, in older fuel-fired models, any byproducts of combustion.

This isolation is critical. It prevents contamination and ensures that any change in the sample's mass is due only to the controlled heating process, leading to accurate and repeatable results. Modern electric furnaces inherently provide this clean environment.

Common Analytical Measurements

Determining Ash Content

This is one of the most common applications. A sample is heated to a high temperature (typically 500-600°C) to completely burn away all organic matter.

The material left behind is the inorganic, non-combustible residue known as ash. This is a critical quality metric in industries like food, animal feed, and coal analysis.

Measuring Moisture Content

To measure moisture, the furnace is set to a much lower temperature, usually just above the boiling point of water (e.g., 105°C).

Heating at this temperature drives off the water without thermally decomposing the rest of the sample. The resulting mass loss corresponds to the sample's moisture content.

Quantifying Volatile Matter

Volatile matter refers to components (other than water) that will burn off when heated in the absence of air. This is a key test in coal analysis.

The sample is heated in a covered crucible to a very high temperature (e.g., 950°C) for a precise, short duration. The mass loss represents the volatile matter, distinct from fixed carbon and ash.

Other High-Temperature Processes

While not strictly for measurement, muffle furnaces are also essential for heat treatment processes that alter a material's physical properties, such as:

- Annealing, hardening, and tempering of metals.

- Sintering powdered materials to form a solid mass.

- Fusing glass or creating enamel coatings.

Understanding the Trade-offs

It's an Indirect Measurement Tool

A muffle furnace is a preparatory instrument. You cannot get a result without ancillary equipment, most importantly a precision analytical balance and a desiccator. The accuracy of your result depends entirely on the quality of your weighing process.

Temperature and Time Are Critical Variables

Slight deviations in final temperature, heating rate, or duration can significantly affect results, especially for volatile matter analysis. Reproducibility depends on a furnace with excellent temperature uniformity and control.

Safety is Paramount

These devices operate at extremely high temperatures, posing a significant burn hazard. Proper personal protective equipment (PPE), including heat-resistant gloves and safety glasses, is non-negotiable.

Making the Right Choice for Your Goal

- If your primary focus is quality control (food, environmental, coal): Your main application will be precise gravimetric analysis to determine the percentage of ash, moisture, or volatile matter.

- If your primary focus is materials science or metallurgy: You will use the furnace primarily for heat treatment processes like annealing or sintering to modify the physical properties of your materials.

- If your primary focus is analytical chemistry: The furnace is an essential tool for sample preparation, used to remove the organic matrix of a sample cleanly before conducting elemental analysis.

Ultimately, a muffle furnace provides the clean, stable, high-temperature environment required to reliably transform a sample for accurate analysis.

Summary Table:

| Measurement Type | Typical Temperature | Purpose |

|---|---|---|

| Ash Content | 500-600°C | Burn off organic matter to measure inorganic residue |

| Moisture Content | ~105°C | Evaporate water content without decomposing sample |

| Volatile Matter | ~950°C | Quantify components that burn off in absence of air |

Ready to enhance your lab's analytical capabilities? A muffle furnace from KINTEK is the cornerstone of precise gravimetric analysis, providing the clean, controlled high-temperature environment essential for accurate ash, moisture, and volatile content measurements. Whether you're in quality control, materials science, or analytical chemistry, our lab equipment ensures reproducible results and process reliability. Contact KINTEK today to find the perfect furnace solution for your laboratory's specific needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the critical point of heat treatment? Master the Key to Steel Transformation

- How do you take care of a muffle furnace? Extend Equipment Life and Ensure Accurate Results

- What is done by ashing in muffle furnace? A Guide to Precise Inorganic Content Analysis

- What are the uses of muffle furnaces? Achieve Precise, Contamination-Free High-Temperature Processing

- What is the body structure of a furnace? Unlocking the Dual-Layer Design for Superior Thermal Control