In essence, a dental porcelain furnace is a specialized, high-temperature oven. It is the cornerstone piece of equipment in a dental laboratory used to transform ceramic powders and materials into strong, aesthetic, and perfectly fitted crowns, veneers, bridges, and other restorations. Its primary job is to execute highly precise heating and cooling cycles, often under a vacuum, to fire, sinter, press, or glaze these materials.

A porcelain furnace is not merely a heat source; it is a precision instrument that enables the fundamental chemical and physical transformation of dental ceramics. Understanding its function is to understand how a lifelike, durable dental prosthesis is actually created from raw materials.

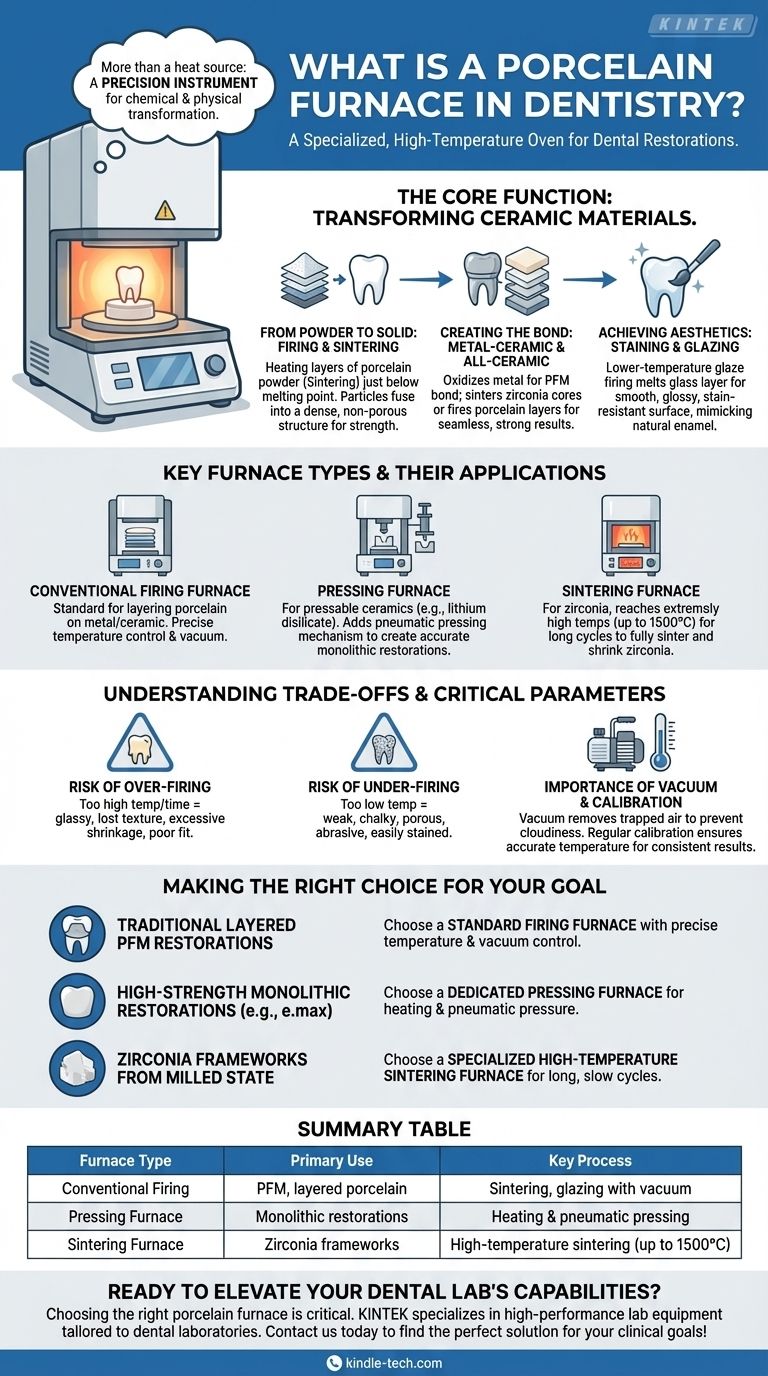

The Core Function: Transforming Ceramic Materials

A porcelain furnace's ultimate purpose is to take inert ceramic materials and convert them into a final restoration that has the required strength, fit, and aesthetics for clinical success. It accomplishes this through several distinct processes.

From Powder to Solid: Firing and Sintering

The most common function is firing, also known as sintering. This involves heating layers of dental porcelain powder to a specific temperature just below their melting point.

At this peak temperature, the individual ceramic particles fuse together, creating a dense, solid, and non-porous structure. This process is what gives the final restoration its strength and durability.

Creating the Bond: Metal-Ceramic and All-Ceramic Applications

For porcelain-fused-to-metal (PFM) restorations, the furnace is first used to oxidize the metal substructure. This creates a thin oxide layer that is chemically compatible with the porcelain, forming a powerful bond between the two materials.

In all-ceramic systems, the furnace sinters the core material (like zirconia) or fires layers of aesthetic porcelain onto a ceramic substructure, ensuring a seamless and strong final product.

Achieving Aesthetics: Staining and Glazing

The final step in creating a restoration is often a glaze firing. This is a lower-temperature cycle that melts a thin layer of glass onto the surface of the restoration.

This glaze provides a smooth, glossy, and stain-resistant surface that mimics the natural luster of tooth enamel. External stains can also be applied and fired on during this cycle to add character and perfect the shade match.

Key Furnace Types and Their Applications

While all are high-heat ovens, dental furnaces are often specialized for specific materials and techniques.

Conventional Firing Furnaces

This is the standard furnace found in most dental labs. It is designed for layering and firing porcelain powders onto metal or ceramic frameworks. Its critical features are precise temperature control and an effective vacuum system.

Pressing Furnaces

Used for pressable ceramics (like lithium disilicate), these furnaces add a pneumatic pressing mechanism to the heating chamber. A ceramic ingot is heated until it becomes molten, and then a plunger presses the fluid ceramic into a mold, creating a highly accurate and strong monolithic restoration.

Sintering Furnaces

Often used for zirconia, these furnaces are designed to reach extremely high temperatures (upwards of 1500°C) and hold them for many hours. This extended cycle is necessary to fully sinter the pre-milled zirconia, shrinking it to its final, dense, and incredibly strong state.

Understanding the Trade-offs and Critical Parameters

Achieving a successful outcome is not as simple as just heating the ceramic. The process is highly sensitive, and incorrect parameters lead to immediate failure.

The Risk of Over-firing

If the temperature is too high or held for too long, the porcelain can "over-fire." This causes it to become glassy, lose its surface texture and vitality, and shrink excessively, which can ruin the fit of the restoration.

The Problem of Under-firing

Conversely, an under-fired restoration will be weak, chalky, and porous. It will be highly abrasive to opposing teeth and will easily absorb stains, leading to clinical failure.

The Importance of the Vacuum

During the main heating phase, a strong vacuum is pulled inside the chamber. This removes trapped air from between the porcelain particles before they fuse. Without a proper vacuum, the final restoration would be cloudy, opaque, and filled with micro-bubbles that severely compromise its strength.

The Critical Nature of Calibration

A furnace's temperature display must be perfectly accurate. Regular calibration is mandatory to ensure that the temperature programmed into the furnace is the actual temperature inside the chamber. An uncalibrated furnace is a primary source of inconsistent and failed ceramic work.

Making the Right Choice for Your Goal

The type of furnace and process you use must be directly matched to the material you are working with and the desired clinical outcome.

- If your primary focus is traditional layered porcelain-fused-to-metal (PFM) restorations: A standard firing furnace with precise temperature and vacuum control is the essential workhorse.

- If your primary focus is high-strength monolithic restorations (e.g., e.max): You must use a dedicated pressing furnace capable of both heating and applying pneumatic pressure.

- If your primary focus is creating zirconia frameworks from a milled state: A specialized, high-temperature sintering furnace capable of long, slow heating and cooling cycles is required.

Ultimately, the dental furnace is the bridge between art and science, transforming a technician's skill into a durable and esthetic clinical reality.

Summary Table:

| Furnace Type | Primary Use | Key Process |

|---|---|---|

| Conventional Firing Furnace | PFM, layered porcelain | Sintering, glazing with vacuum |

| Pressing Furnace | Monolithic restorations (e.g., e.max) | Heating & pneumatic pressing |

| Sintering Furnace | Zirconia frameworks | High-temperature sintering (up to 1500°C) |

Ready to elevate your dental lab's capabilities?

Choosing the right porcelain furnace is critical for producing strong, aesthetic, and perfectly fitting restorations. At KINTEK, we specialize in providing high-performance lab equipment tailored to dental laboratories. Whether you need a precise firing furnace for PFM work, a robust pressing furnace for monolithic restorations, or a high-temperature sintering furnace for zirconia, we have the solution to match your clinical goals and materials.

Our expertise ensures you get the right equipment for consistent, high-quality results. Don't leave your outcomes to chance—invest in reliability and precision.

Contact us today to discuss your specific needs and find the perfect porcelain furnace for your lab!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What does sintering do to zirconia? Unlock Its Full Strength and Aesthetic Potential

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- How does firing temperature affect ceramics? Master the Key to Perfect Strength and Aesthetics

- What is the shrinkage of zirconia during sintering? Mastering the 20-25% Dimensional Change

- What is the temperature of the burnout oven? Master the Multi-Stage Cycle for Flawless Castings

- How do dental ceramic ovens process materials? Master Heat and Pressure for Perfect Restorations

- What are the different types of temperature calibration systems used in porcelain furnaces? Ensure Precision for Every Ceramic Type

- What methods are used to control the temperature for sintering dental zirconia? Achieve Precise Results with KINTEK