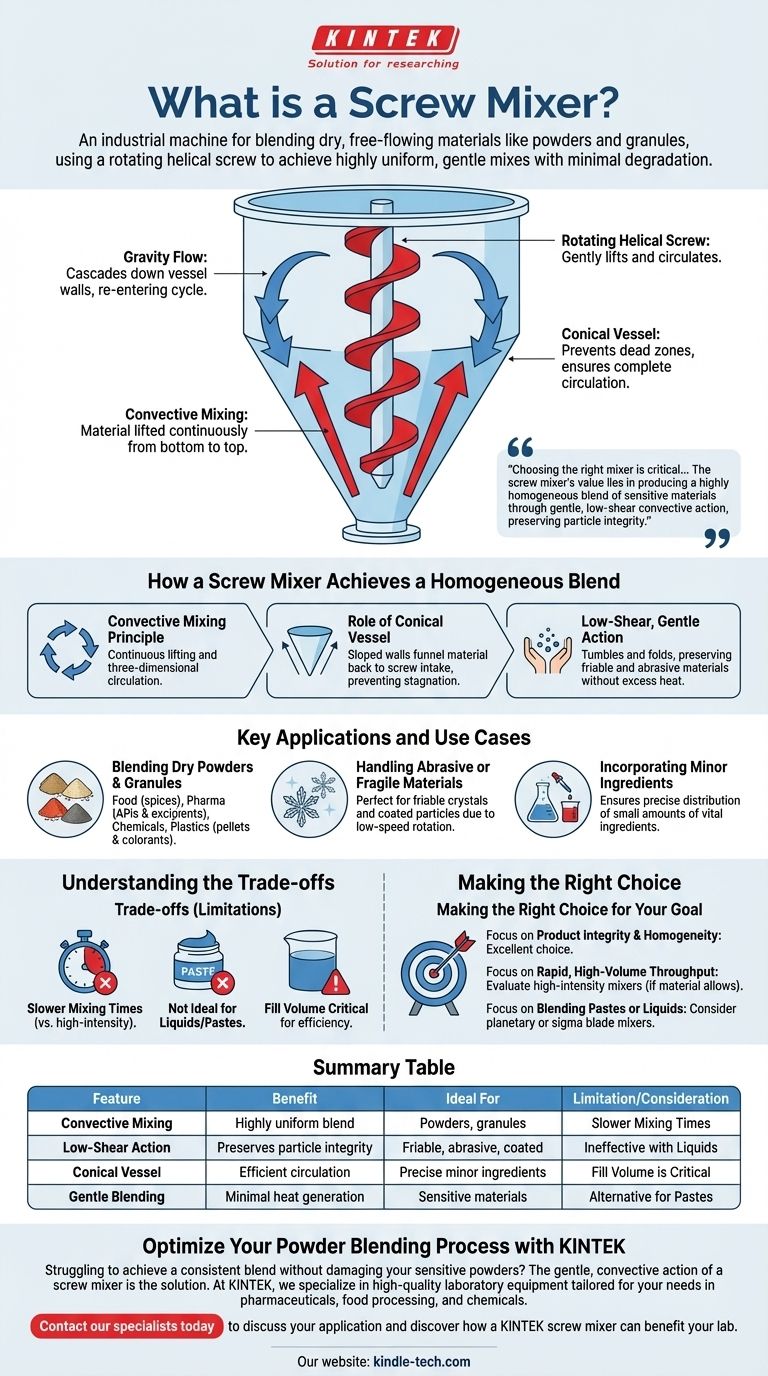

At its core, a screw mixer is an industrial mixing machine designed to blend dry, free-flowing materials like powders and granules. It utilizes a rotating, helical screw, typically within a conical vessel, to gently lift and circulate materials, achieving a highly uniform and consistent blend with minimal product degradation.

Choosing the right mixer is a critical process decision that directly impacts product quality and consistency. The screw mixer's unique value lies in its ability to produce a highly homogeneous blend of sensitive, dry materials through a gentle, low-shear convective action, preserving the physical integrity of the individual particles.

How a Screw Mixer Achieves a Homogeneous Blend

The effectiveness of a screw mixer comes from its elegant and efficient mixing principle, which creates a complex but predictable flow of material within the vessel.

The Principle of Convective Mixing

The primary mechanism is convective mixing. The rotating screw, located centrally or orbiting the vessel wall, continuously lifts material from the bottom of the batch and transports it to the top.

Once at the top, the material cascades down the sides of the vessel by gravity, re-entering the mixing cycle at the bottom. This creates a constant, three-dimensional circulation that ensures every particle is kept in motion.

The Role of the Conical Vessel

Most industrial screw mixers utilize a cone-shaped vessel. This design is not arbitrary; it works in perfect concert with the screw.

The sloped walls of the cone funnel material directly back towards the intake of the screw, preventing "dead zones" where material might stagnate. This guarantees that the entire batch is consistently incorporated into the mixing flow.

Low-Shear, Gentle Action

Unlike high-speed, high-impact mixers, the screw mixer's action is remarkably gentle and low-shear. It tumbles and folds the materials together rather than forcing them against each other with high velocity.

This makes it the ideal choice for applications where the particle size, shape, or composition must be preserved without generating excess heat from friction.

Key Applications and Use Cases

The screw mixer's specific strengths make it a preferred tool across several key industries for very specific tasks.

Blending Dry Powders and Granules

This is the most common application. Industries like food processing, pharmaceuticals, chemicals, and plastics rely on screw mixers to combine different powders with high precision.

Examples include creating uniform spice blends, mixing active pharmaceutical ingredients (APIs) with excipients, or blending plastic pellets with colorants and additives.

Handling Abrasive or Fragile Materials

Because the mixing action is so gentle, it is perfectly suited for materials that are friable (easily crumbled) or abrasive.

The low-speed rotation and lack of forceful impacts prevent the breakdown of delicate crystals, coated particles, or other sensitive structures that would be destroyed in a more aggressive mixer.

Incorporating Minor Ingredients

The machine's systematic circulation is extremely effective at achieving high levels of homogeneity. This is critical when a very small amount of a vital ingredient must be perfectly distributed throughout a large batch.

Understanding the Trade-offs

No single piece of equipment is perfect for every task. To use a screw mixer effectively, you must understand its limitations.

Limitation: Slower Mixing Times

The trade-off for gentle, low-shear mixing is speed. A screw mixer typically requires longer batch times compared to high-intensity plough or ribbon blenders.

Limitation: Not Ideal for Liquids or Pastes

The convective mixing principle is optimized for free-flowing solids. While some variations can handle small amounts of liquid addition, a standard screw mixer is not effective for blending high-viscosity pastes or liquid-liquid mixtures.

Consideration: Fill Volume is Critical

For a screw mixer to work efficiently, it must be filled to the correct level. Underfilling or overfilling the vessel can disrupt the circulation pattern and significantly compromise the final blend uniformity.

Making the Right Choice for Your Goal

Selecting the correct mixer requires matching the equipment's core strengths to your process objectives.

- If your primary focus is product integrity and homogeneity: A screw mixer is an excellent choice, especially for sensitive powders, coated particles, or when avoiding heat generation is critical.

- If your primary focus is rapid, high-volume throughput: You may need to evaluate a higher-intensity mixer, but only if your materials can withstand the increased shear forces and potential for degradation.

- If your primary focus is blending heavy pastes or liquids: A screw mixer is the wrong tool; you should investigate equipment like planetary mixers, sigma blade mixers, or high-shear dispersers.

Ultimately, understanding the screw mixer's principle of gentle, convective blending is the key to deploying it effectively in your process.

Summary Table:

| Feature | Benefit | Ideal For |

|---|---|---|

| Convective Mixing | Highly uniform blend without dead zones | Powders, granules, free-flowing solids |

| Low-Shear Action | Preserves particle integrity; minimal heat generation | Friable, abrasive, or coated materials |

| Conical Vessel | Efficient material circulation; prevents stagnation | Precise distribution of minor ingredients |

| Limitation | Consideration | Alternative Needed For |

| Slower Mixing Times | Trade-off for gentleness | High-speed, high-shear applications |

| Ineffective with Liquids | Optimized for dry solids | Paste or liquid blending |

Optimize Your Powder Blending Process with KINTEK

Struggling to achieve a consistent blend without damaging your sensitive powders? The gentle, convective action of a screw mixer is the solution for preserving product integrity while ensuring perfect homogeneity.

At KINTEK, we specialize in providing high-quality laboratory equipment, including screw mixers tailored for your specific needs. Whether you're in pharmaceuticals, food processing, or chemicals, our experts can help you select the ideal mixer to enhance your product quality and process efficiency.

Contact our specialists today to discuss your application and discover how a KINTEK screw mixer can benefit your lab.

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Oscillating Orbital Shaker

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- What are the principles of a ball mill? Master Impact & Attrition for Perfect Particle Size

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What are the components of a colloid mill? Master the Core Mechanism for Superior Emulsification

- Why is it necessary to use ultrafine grinding equipment for boron carbide? Achieve High Density in Hard Ceramics

- What is the role of mechanical mixing equipment in preparing tungsten-coated diamond precursors for uniform coatings?

- What is grinding media made of? Select the Right Material for Your Milling Process

- Why use an agate mortar for Li2-xZr1-xTaxCl6 pre-mixing? Ensure Homogeneity & Purity

- What technical problem does a micronizing mill solve for LSTH solid electrolytes? Enhance Sintering & Density