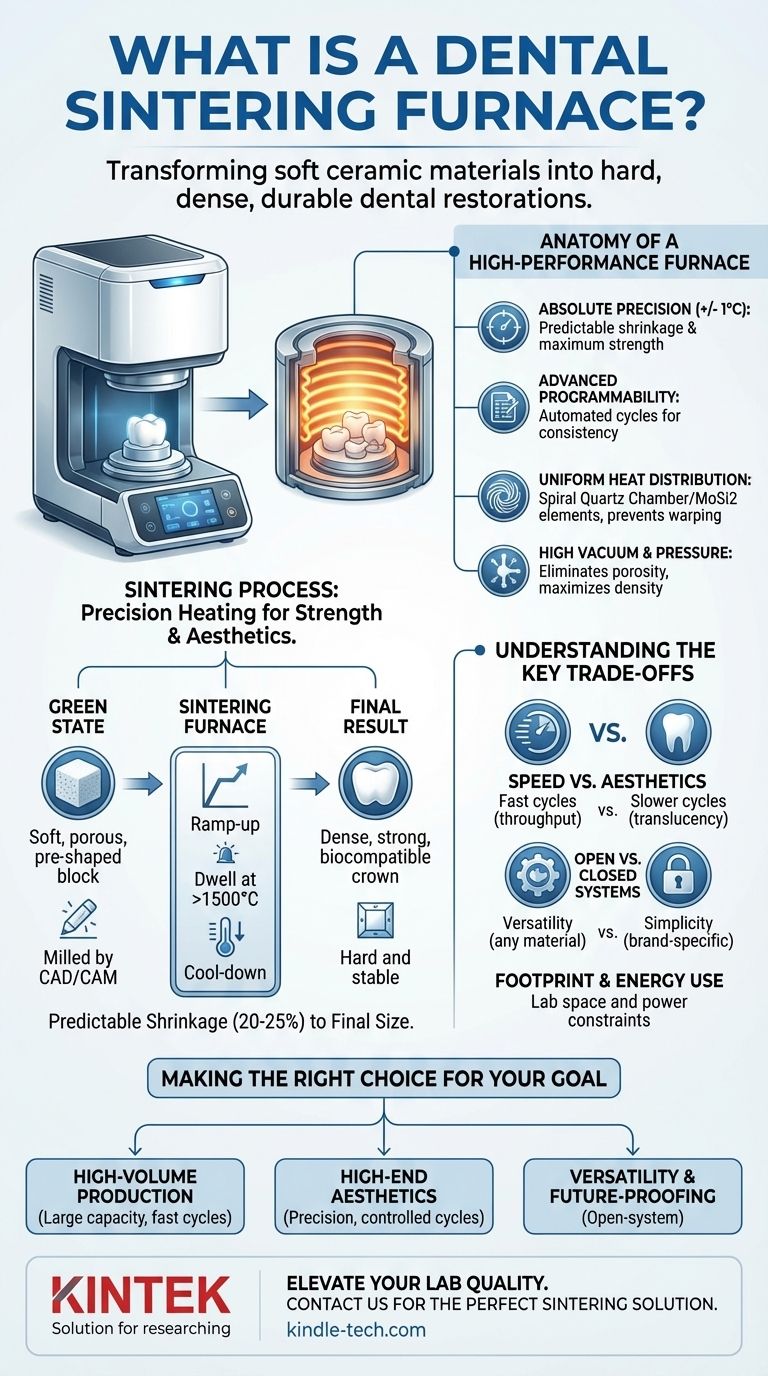

In short, a dental sintering furnace is a specialized high-temperature oven used in dental laboratories. It transforms soft, pre-shaped ceramic materials like zirconia into a hard, dense, and durable final state suitable for dental restorations such as crowns, bridges, and implants. This process, known as sintering, is what gives modern ceramic restorations their exceptional strength and aesthetic properties.

The core function of a sintering furnace is not just to generate heat, but to deliver it with extreme precision. Its ability to meticulously control temperature, heating rates, and dwell times is the single most critical factor in guaranteeing the strength, fit, and final appearance of a ceramic dental restoration.

How Sintering Transforms Dental Materials

To understand the furnace's role, you must first understand the material's journey. The process turns a fragile, chalk-like block into one of the strongest materials used in dentistry.

The "Green State" Material

Dental restorations made from zirconia begin as a pre-sintered or "green state" block. In this form, the material is soft enough to be easily milled by a CAD/CAM machine into the precise shape of the final crown or bridge.

However, at this stage, the restoration is porous, oversized, and extremely fragile.

The Sintering Process

The milled "green state" restoration is placed into the sintering furnace. The furnace then executes a precise, pre-programmed heating cycle, which involves three key phases:

- Ramp-up: The temperature is gradually increased over several hours to prevent thermal shock, which could crack the restoration.

- Dwell: The furnace holds the material at its peak sintering temperature (often above 1,500°C for zirconia) for a specific duration. During this phase, the individual ceramic particles fuse together, eliminating pores and causing the material to densify.

- Cool-down: The temperature is slowly and controllably lowered back to room temperature.

This entire cycle causes the restoration to shrink by a predictable amount—typically 20-25%—to its final, intended size and high-density state.

The Final Result: Strength and Stability

After cooling, the restoration emerges from the furnace fully densified, incredibly strong, and biocompatible. It is now ready for final staining, glazing, and placement in the patient's mouth.

The Anatomy of a High-Performance Furnace

Not all furnaces are created equal. The consistency and quality of your lab's output depend directly on the furnace's technical capabilities.

Absolute Temperature Precision

This is the most critical feature. High-quality furnaces maintain temperature accuracy to within +/- 1°C. This precision ensures predictable shrinkage, preventing ill-fitting restorations, and guarantees the material achieves its maximum strength without being overheated, which can compromise aesthetics.

Advanced Programmability

Modern furnaces are fully automated and programmable. They often feature large touch screens and come with built-in programs for various types of zirconia and other ceramics. This allows technicians to select the material manufacturer's recommended cycle with a single touch, ensuring consistency and saving time.

Uniform Heat Distribution

The quality of the heating elements and the design of the firing chamber are vital. Many top-tier furnaces use a spiral quartz chamber or high-purity molybdenum disilicide (MoSi2) heating elements. This ensures the entire restoration is heated evenly, preventing hot spots that can cause warping or internal stress.

High Vacuum and Pressure Capabilities

While not standard on all sintering furnaces, some advanced models, particularly hot-pressing furnaces, incorporate high vacuum and pressure. A vacuum removes atmospheric impurities that could interfere with the material's integrity, while applied pressure helps achieve maximum density and eliminate any residual porosity.

Understanding the Key Trade-offs

Choosing a furnace involves balancing competing priorities related to speed, cost, and versatility.

Speed vs. Final Aesthetics

Many modern furnaces offer "speed" sintering cycles that can be completed in a fraction of the time of traditional cycles. While this dramatically increases throughput, it can sometimes come at a cost.

Faster heating and cooling can impact the final translucency of some zirconia materials, making them appear more opaque. For high-end anterior cases where aesthetics are paramount, a slower, conventional cycle often yields a superior result.

Open vs. Closed Systems

Some equipment manufacturers sell "closed" systems, where their furnace is optimized exclusively for their brand of ceramic materials. This can offer simplicity and guaranteed results but locks you into a single supplier.

An "open system" furnace provides the flexibility to create custom programs for any ceramic material from any manufacturer, offering greater versatility and adaptability as new materials enter the market.

Footprint and Energy Use

A furnace is a significant piece of equipment. Lab space and power supply are practical constraints. Larger-capacity furnaces can sinter more units simultaneously but have a larger physical footprint and higher energy consumption. Compact, energy-efficient models are available but may limit batch size.

Making the Right Choice for Your Goal

Your decision should be guided by the specific needs and priorities of your dental laboratory.

- If your primary focus is high-volume production: Choose a furnace with a large chamber capacity and proven reliability to handle multiple cases with fast, repeatable cycles.

- If your primary focus is high-end aesthetic restorations: Prioritize a furnace with exceptional temperature accuracy and the flexibility to customize slow, controlled cycles to maximize material translucency.

- If your primary focus is versatility and future-proofing: Invest in an open-system furnace that allows you to adapt to the full spectrum of current and future ceramic materials.

Ultimately, the sintering furnace is the heart of a modern dental lab, acting as the final guarantor of quality for every ceramic restoration you produce.

Summary Table:

| Feature | Impact on Dental Restoration |

|---|---|

| Temperature Precision (+/- 1°C) | Ensures predictable shrinkage and maximum material strength |

| Programmable Cycles | Guarantees consistency and saves time with automated processes |

| Uniform Heat Distribution | Prevents warping and ensures even sintering for perfect aesthetics |

| High Vacuum/Pressure (Advanced Models) | Eliminates porosity for superior density and material integrity |

Ready to elevate the quality and efficiency of your dental lab?

A precise sintering furnace is the cornerstone of producing durable, perfectly-fitting ceramic crowns and bridges. At KINTEK, we specialize in high-performance lab equipment designed specifically for dental laboratories. Our sintering furnaces deliver the exact temperature control, uniform heating, and programmability you need to achieve consistent, high-quality results for every restoration.

Contact us today to find the perfect sintering solution for your lab's unique needs—whether you focus on high-volume production or high-end aesthetic cases.

Get in touch with our experts now!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results