At its core, a temperature control system for a digital application is a dedicated mechanism designed to monitor a component's heat and actively manage it to stay within a predetermined safe and efficient operating range. This system is crucial for the performance and longevity of modern electronics, from the CPU in your laptop to complex industrial controllers.

The fundamental purpose of a digital temperature control system is not just to prevent overheating, but to actively balance performance, power consumption, and component lifespan by intelligently managing thermal energy.

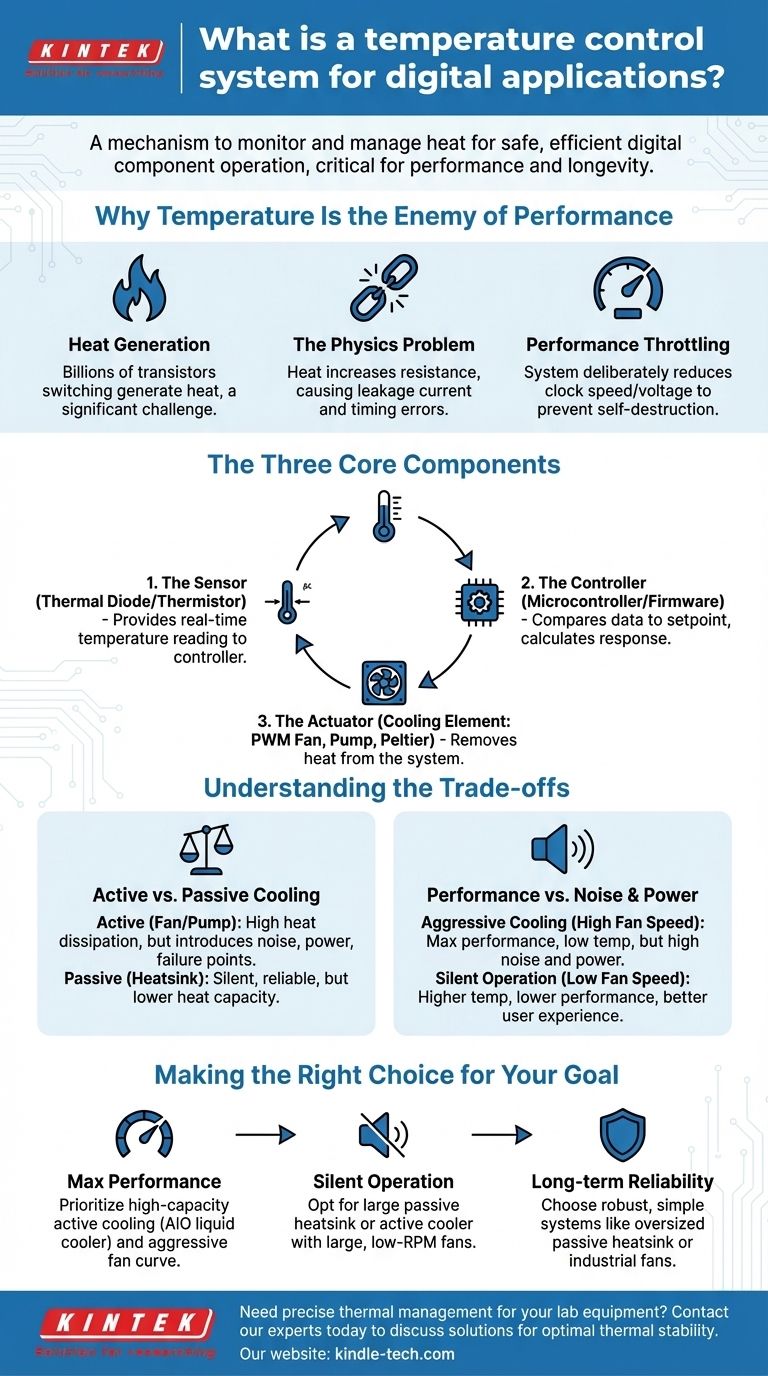

Why Temperature Is the Enemy of Performance

Modern digital circuits, like CPUs and GPUs, are packed with billions of transistors. Every time these transistors switch, they generate a small amount of heat. At high speeds, this collective heat becomes a significant engineering challenge.

The Physics of the Problem

Semiconductors have a strict thermal budget. As temperature rises, the electrical resistance changes, and electrons move more erratically.

This leads to two primary problems: an increase in leakage current, where transistors waste power even when idle, and a higher risk of timing errors, where signals don't arrive when they should, causing data corruption or system crashes.

Performance Throttling: The Built-in Defense

To prevent self-destruction, nearly all modern processors implement thermal throttling.

When a built-in sensor detects a critically high temperature, the processor’s control logic deliberately reduces its own clock speed and voltage. This reduces heat generation at the direct cost of computational performance.

The Three Core Components of a Control System

A temperature control system functions as a continuous feedback loop. This loop is comprised of three essential parts working in concert.

1. The Sensor

This is the nerve ending of the system. It's typically a thermal diode integrated directly onto the silicon die of the processor or a thermistor placed near a critical component.

Its sole job is to provide an accurate, real-time temperature reading to the controller.

2. The Controller

This is the brain. The controller can be a dedicated microcontroller, a function within a larger chipset, or even software running on the main CPU.

It constantly reads the data from the sensor and compares it to a pre-defined setpoint or temperature curve stored in its firmware (like the BIOS/UEFI on a PC). Based on the difference, it calculates the necessary response.

3. The Actuator (Cooling Element)

This is the muscle that carries out the controller's commands. It's the physical component that removes heat from the system.

Common actuators include fans, which use Pulse Width Modulation (PWM) to precisely vary their speed, pumps in a liquid cooling loop, or even a Thermoelectric Cooler (Peltier device) for high-precision applications.

Understanding the Trade-offs

Implementing a temperature control system is not about achieving the lowest possible temperature; it's about finding the right balance for a specific goal.

Active vs. Passive Cooling

Active cooling involves actuators with moving parts, like fans and pumps. It is highly effective at dissipating large amounts of heat but introduces noise, complexity, power consumption, and more potential points of failure.

Passive cooling relies solely on a heatsink to dissipate heat into the ambient air through convection. It is completely silent and highly reliable but has a much lower capacity for heat dissipation, limiting it to lower-power components.

Performance vs. Noise and Power

An aggressive cooling profile that keeps temperatures very low will maximize performance by preventing throttling. However, this often requires fans to run at high speeds, creating significant noise and consuming more power.

Conversely, a system optimized for silence will allow temperatures to run higher, potentially sacrificing some peak performance for a better user experience in a quiet environment.

Making the Right Choice for Your Goal

The ideal temperature management strategy depends entirely on the primary objective of the digital application.

- If your primary focus is maximum, sustained performance: Prioritize a high-capacity active cooling solution, such as a large air cooler or an All-in-One (AIO) liquid cooler, and configure an aggressive fan curve.

- If your primary focus is silent operation: Opt for a large passive heatsink where possible or an active cooler with large, low-RPM fans designed for quiet operation.

- If your primary focus is long-term reliability in a harsh environment: Choose robust, simple systems. An oversized passive heatsink or high-quality industrial fan offers more reliability than complex liquid cooling with multiple failure points.

Ultimately, effective thermal management is the invisible foundation that enables the power and stability of all modern digital systems.

Summary Table:

| Component | Role | Key Examples |

|---|---|---|

| Sensor | Monitors temperature | Thermal diode, Thermistor |

| Controller | Processes data & makes decisions | Microcontroller, Firmware (BIOS/UEFI) |

| Actuator | Executes cooling commands | PWM Fan, Liquid Pump, Peltier Device |

| Trade-off | Key Consideration | Impact |

| Active vs. Passive | Cooling method | Performance vs. Silence/Reliability |

| Performance vs. Noise | User experience | Maximum speed vs. Quiet operation |

Need precise thermal management for your lab equipment? Just as digital systems rely on temperature control for peak performance, your laboratory instruments require the same precision for accurate and reliable results. KINTEK specializes in high-quality lab equipment and consumables designed for optimal thermal stability. Contact our experts today to discuss how our solutions can enhance your lab's efficiency and protect your critical investments.

Visual Guide

Related Products

- Shaking Incubators for Diverse Laboratory Applications

- Infrared Heating Quantitative Flat Plate Press Mold

- Manual Lab Heat Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What critical reaction conditions does a shaking incubator provide? Optimize Cassava Cellulose Enzymatic Hydrolysis

- How does a constant temperature incubator shaker facilitate the enzymatic hydrolysis of lignocellulosic materials?

- Why is a thermostatic shaker required for SSF of rice husk solids? Maximize Your Ethanol Yield with Precision Agitation

- Why is a constant temperature shaking incubator necessary for antibacterial experiments? Ensure Valid Results

- What function does a constant temperature shaker perform during adsorption performance tests? Ensure Data Accuracy